What to Do with the Smell of Laser-cut Wood Material?

Updated Nov 20,2024

Updated Nov 20,2024

Why does it smell?

If there is insufficient power and speed, it takes more time to cut. In this case, it is more likely to cause black edges and a bad smell, sometimes even burnt wood, which gives a burnt smell.

How to reduce the smell?

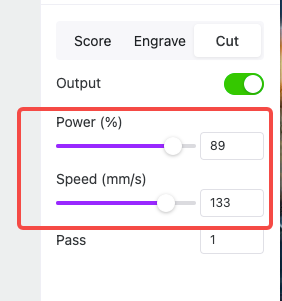

Increase the working power and speed. This can accelerate the cutting process and reduce the chances of black edges and smell.

|  |

Use masking tape. By doing so, the cutting surface would be the tape, instead of the board.

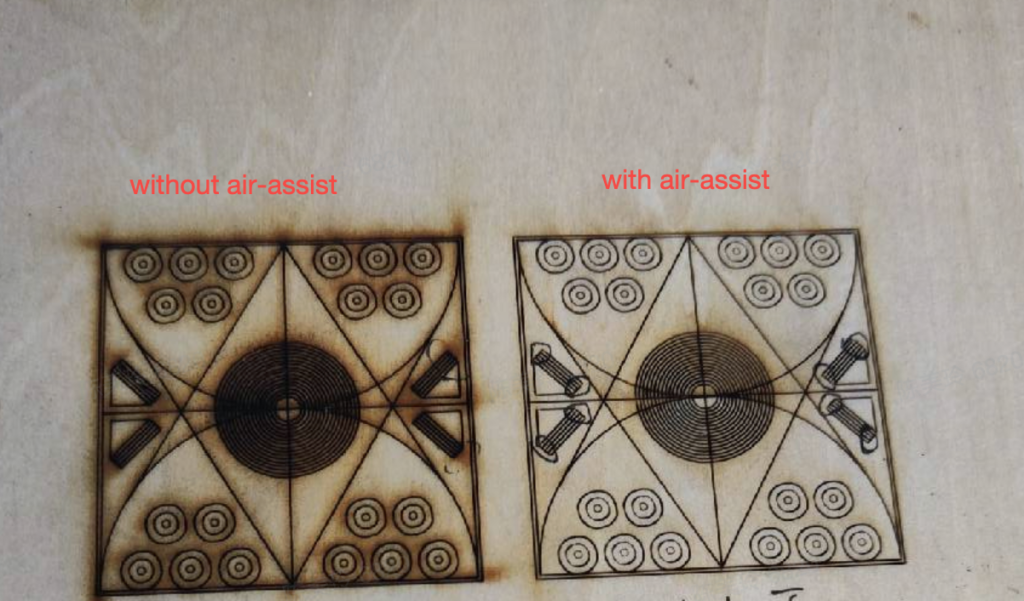

Use an air pump. It can blow away the particulate emission from gasification during the working process.

Wipe and rinse the charred piece. You can also wipe the small molecules with a nano sponge.

If there is still a residual smell, try airing it out in an open space.

Preview

Was this page helpful?

14 out of 14 found this helpful

Help Ticket

Use this help ticket to submit your issue. We will respond within 1 business day

Submit a Ticket Tags

Help Ticket

Use this help ticket to submit your issue. We will respond within 1 business day

Submit a Ticket

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.