xTool Creative Space (XCS) is an all-in-one software for graphic designing and editing, laser process setting, and machine controlling.

Connect xTool S1 to XCS

Minimum and recommended requirements for iPad

Item | Minimum configuration | Recommended configuration |

Processor | A10 | A12 or later |

Operating system | iPadOS 15 or later (except for iOS15.4.1, at which XCS may have exceptions) | |

RAM | 4 GB | 6 GB or more |

Storage | 32 GB | 64 GB or more |

- With the minimum configurations, all the functions of XCS can be used properly. When you import a complex image, however, XCS may fail to run smoothly.

- With the recommended configurations, XCS can run more smoothly when you import and edit a complex image, the software delay may be shorter, and the performance is better.

Download and install XCS

(1) Search for "xTool Creative Space" in App Store or Google Play, or visit xtool.com/software to download and install XCS.

(2) Open XCS. On the top-left corner, tap the icon to open the Settings panel and select the language you use.

Connect xTool S1 to Wi-Fi

You can connect xTool S1 to a Wi-Fi network by using XCS on your iPad or your computer.

- On the iPad

(1) Open XCS on your iPad, and tap New project.

(2) On the top-right corner of your screen, tap Connect Device.

(3) On the Connect device window, tap + Wi-Fi setting in the top-right corner. Then, select S1 and tap Next.

Note: The device supports only 2.4 GHz Wi-Fi networks.

(4) Long press the button on xTool S1 until the annular indicator blinks purple. On XCS, tap OK, next.

(5) Follow the onscreen instructions to connect xTool S1 to a Wi-Fi network.

- On the computer

(1) Follow the instructions on "Operate xTool S1 with XCS on Your Computer" to connect xTool S1 with XCS on the computer through the USB cable.

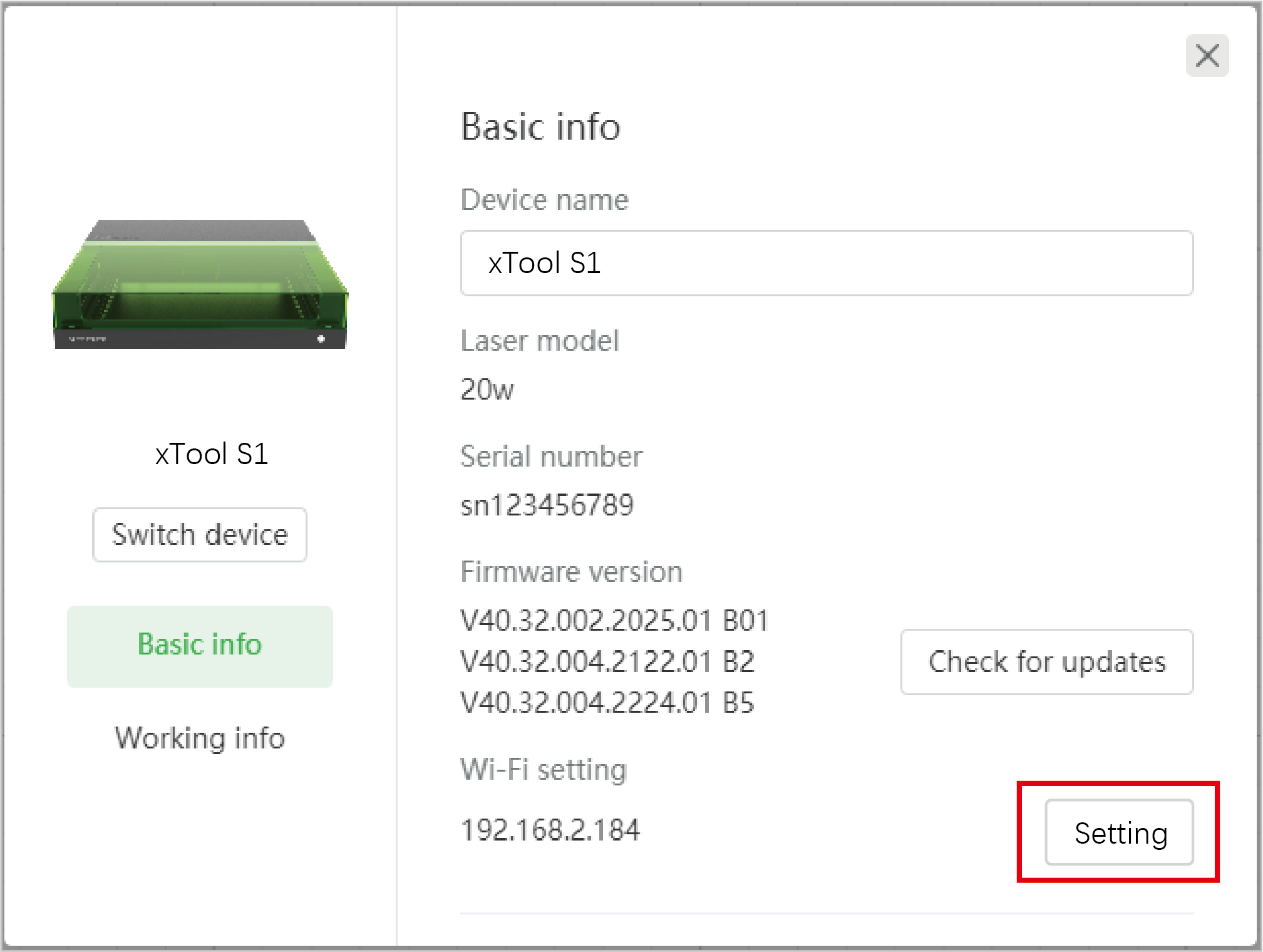

(2) On the computer, click the icon on the top-right corner of XCS.

(3) View the device name and click Setting in the Wi-Fi setting section.

(4) Select a Wi-Fi network and enter the password. Then, click Next to connect xTool S1 to the Wi-Fi.

Note: The device supports only 2.4 GHz Wi-Fi networks.

Connect xTool S1 to XCS

(1) Ensure that your iPad and xTool S1 are connected to the same Wi-Fi network. On the top-right corner of your screen, tap Connect Device.

(2) On the device list, tap the name of your xTool S1 to connect it. After xTool S1 is connected, its annular indicator turns solid purple.

Note: If you cannot find your device on the list, you can try tapping Refresh.

Set up xTool S1 in XCS

- On the top right corner of XCS, click the gear icon next to the xTool S1 image to open the device setting window.

- Set up xTool S1 based on your needs.

- Device name: Set a new name for your xTool S1.

- Flame alarm: If a flame is detected, xTool S1 will pause processing and raise the alarm.

- Stops when moved: If xTool S1 is moved or tilted during processing, it will pause processing.

- Fill light brightness: Adjust the brightness of the fill light in the working area.

- Time the purifier continues to work:

If you connect xTool S1 with the smoke purifier, you can set the duration at which the smoke purifier continues to work after xTool S1 stops processing. By setting this parameter, you can make the smoke purifier work longer to absorb the remaining smoke. - Auto-adjustment for the air assist set:

If you connect xTool S1 with the air assist set (updated version), you can turn on Auto-adjustment for the air assist set.

Set the airflow levels respectively for engraving and cutting. The airflow increases from 1 to 4, and 0 means no airflow. During processing, XCS adjusts the airflow based on your setting.

Note:

For an air assist set that is not of the updated version, you cannot set Auto-adjustment for the air assist set for it.

You are advised to use a small airflow for engraving and a large airflow for cutting.

The supported processing modes

XCS that runs on iPad supports the following processing modes:

- Laser flat: processes flat materials

- Laser cylindrical: processes regular or irregular cylindrical materials

To use this mode, you need to use xTool S1 with the rotary attachment and the riser base (the ordinary version or the version that supports the conveyer feeder).

For more information on how to use xTool S1 with the rotary attachment in Laser cylindrical mode, see Use xTool S1 with the Rotary Attachment.

Note: XCS that runs on the mobile phone or iPad does not support the Laser curve and Conveyor feeder modes. If you need to use these two modes, please use XCS on your computer.

Use xTool S1 in the Laser flat mode

Notes

xTool S1 supports different material thicknesses when working with different accessories.

Combinations of xTool S1 and accessories | Supported material thickness (H) |

xTool S1 | 0 mm < H ≤ 42 mm |

xTool S1 + slats | 0 mm < H ≤ 34 mm |

xTool S1 + honeycomb panel | 0 mm < H ≤ 15 mm |

xTool S1 + riser base | 70 mm ≤ H ≤ 125 mm |

xTool S1 + riser base + honeycomb panel | 0 mm < H ≤ 99 mm |

xTool S1 + riser base supporting conveyor feeder | 15.5 mm ≤ H ≤ 133.5 mm |

xTool S1 + riser base supporting conveyor feeder + honeycomb panel | 0 mm < H ≤ 106.5 mm |

1. Place the material

Open the lid of xTool S1, and place the material to be processed on the baseplate.

.png)

Note: To cut a material, you are advised to place the slats or honeycomb panel on the baseplate before placing the material. The slats or honeycomb panel can reduce the burned area on the back of the material and protect the baseplate..png)

2. Open or create a project

You can open a project to start processing or create a new project. If you create a new project, you need to design patterns and set parameters from scratch.

- Open a project

On the home screen of XCS, the saved projects are displayed in the Projects section. You can slide left or right to select the project you want to use and tap to open it.

Note: The project file can contain information such as processing patterns, processing modes, and processing parameters. However, if the machine model, processing mode, or material thickness used in the project varies from the current situation, you need to reset the corresponding parameters.

- Create a new project

On the home screen of XCS, tap New project.

3. Select the processing mode and material name

(1) On the right side of XCS, select Laser flat.

(2) In the drop-down list of Material, select the name of your material.

Note 1:

If you can't find your material in the list, you can click + More to search among more materials in the xTool SELECTED online material center.

If you still can't find the name of your material, you can select User-defined material.

Note 2:

After you select a material on the material list or xTool Selected online material center, the software will automatically focus and set other parameters for laser processing.

The default settings apply to xTool materials. You can adjust the settings based on your needs.

(3) Turn on or off Laser module position based on your need.

Note: If you turn on Laser module position, XCS will display the position of the laser module in real time. The red cross in the canvas indicates the laser module, and the coordinates of the laser module are shown in the Laser module position section.

4. Set the laser focus

xTool S1 has a distance sensor, which can measure the distance between the laser module and the material surface. You can also manually measure and calculate the distance between the laser module and the material surface, and input the obtained values into XCS. Before processing, xTool S1 will perform auto-focus based on the Distance parameter.

- Auto measure

(1) Move the laser module over the material. Ensure that the locating spot falls on the surface of the material.

(2) On the right side of XCS, click the  icon under the Distance parameter, and xTool S1 will automatically measure the distance from the laser module to the material surface.

icon under the Distance parameter, and xTool S1 will automatically measure the distance from the laser module to the material surface.

.png)

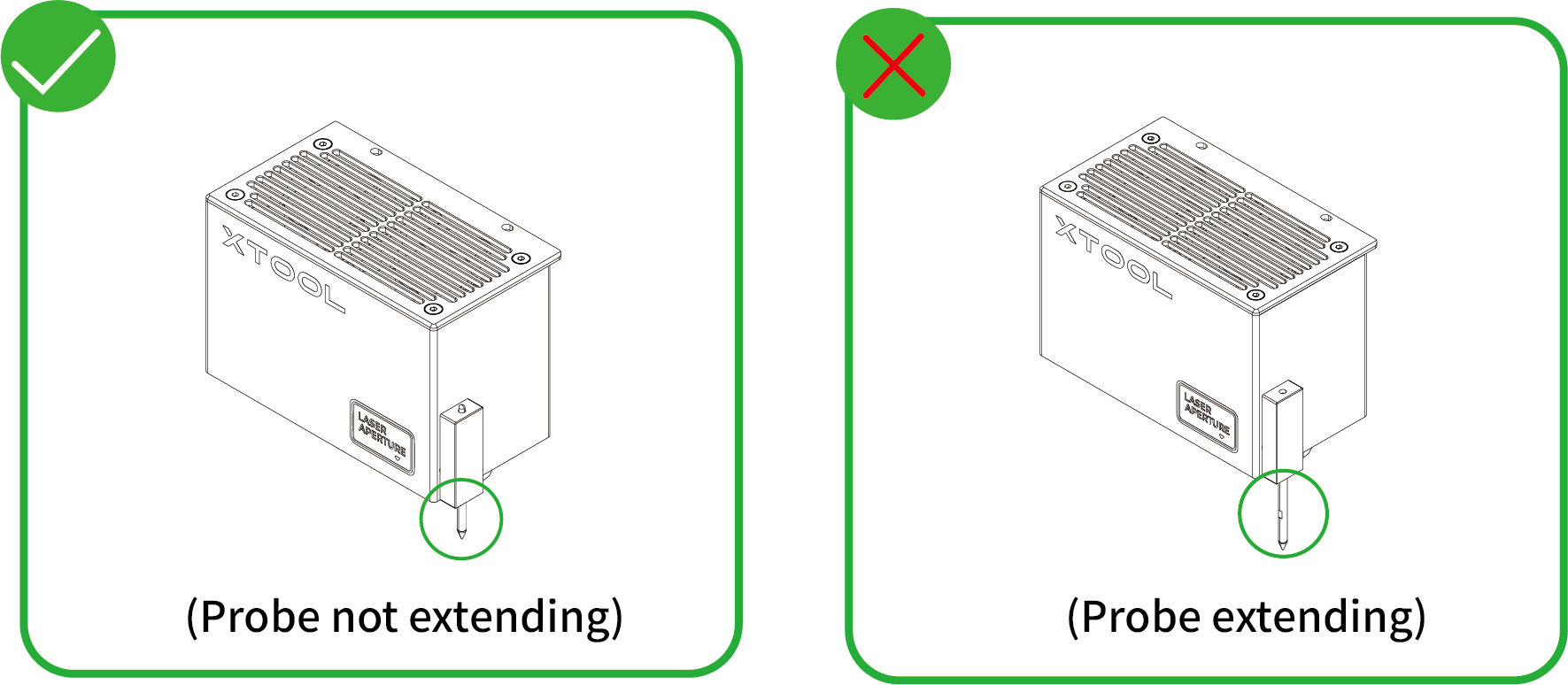

Note: Before auto-measure, ensure that the probe of the distance sensor is not extending.

- Manual measure

(1) Use a ruler to measure the distance from the surface of the material to the top of the laser module.

(2) Subtract 100 mm (3.937 in) from the measured value from step (1), and input the calculated value into the Distance parameter on the right of XCS.

5. Design objects for processing

(1) Use the tools to the left side of the canvas to create objects. You can import images, insert shapes, enter text, or draw vector graphics.

.png)

Note: XCS supports importing the following image formats: SVG, DXF, JPG, JPEG, PNG, BMP, etc.

(2) Select the objects and use the toolbar above the canvas to further edit the objects.

.png)

Note: If you select an image object, you can edit the image by using the tools to the right side of the canvas.

6. Set parameters for processing

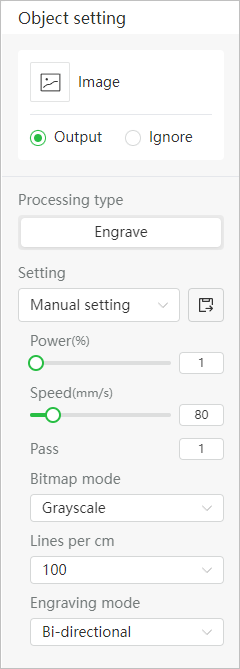

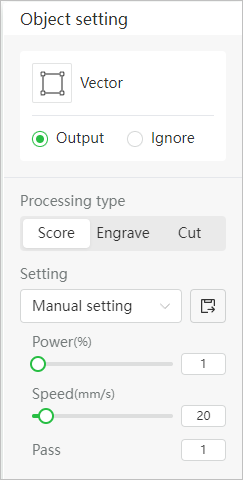

Select objects on the canvas. Then, on the right side of XCS, set parameters for the selected objects.

Note:

You need to set parameters for every object. A missed object may fail to be processed.

The parameters that can be set for bitmap objects and vector objects are different. You can select multiple objects of the same type and set parameters for them at once.

- For bitmaps

- For vectors

Note: For a detailed explanation of each parameter, see support.xtool.com/hc/en-us/categories/9157502370455-XCS.

7. Preview the processing area

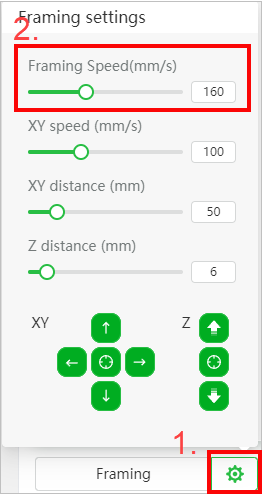

(1) At the bottom right corner of the software, click the .png) icon next to the framing button to set the framing speed.

icon next to the framing button to set the framing speed.

Note: You can tap the arrow buttons to control the movement of the laser module. The other three parameters allow you to configure how the laser module moves with every tap on an arrow button.

XY speed (mm/s): The moving speed of the laser module in X and Y directions.

XY distance (mm): The moving distance of the laser module with each tap on an XY arrow button.

Z distance (mm): The moving distance of the laser module with each tap on a Z arrow button.

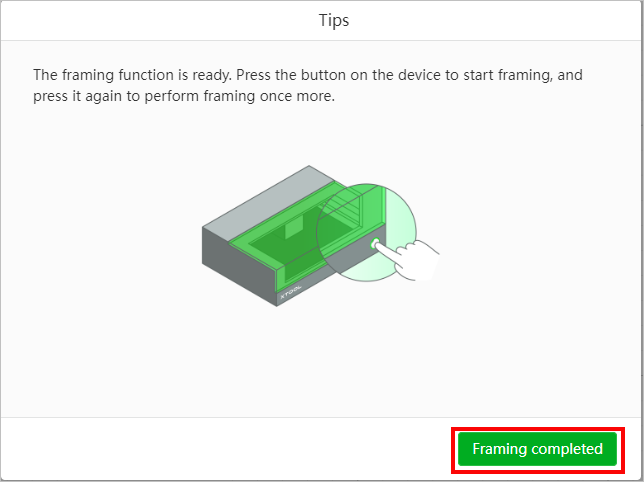

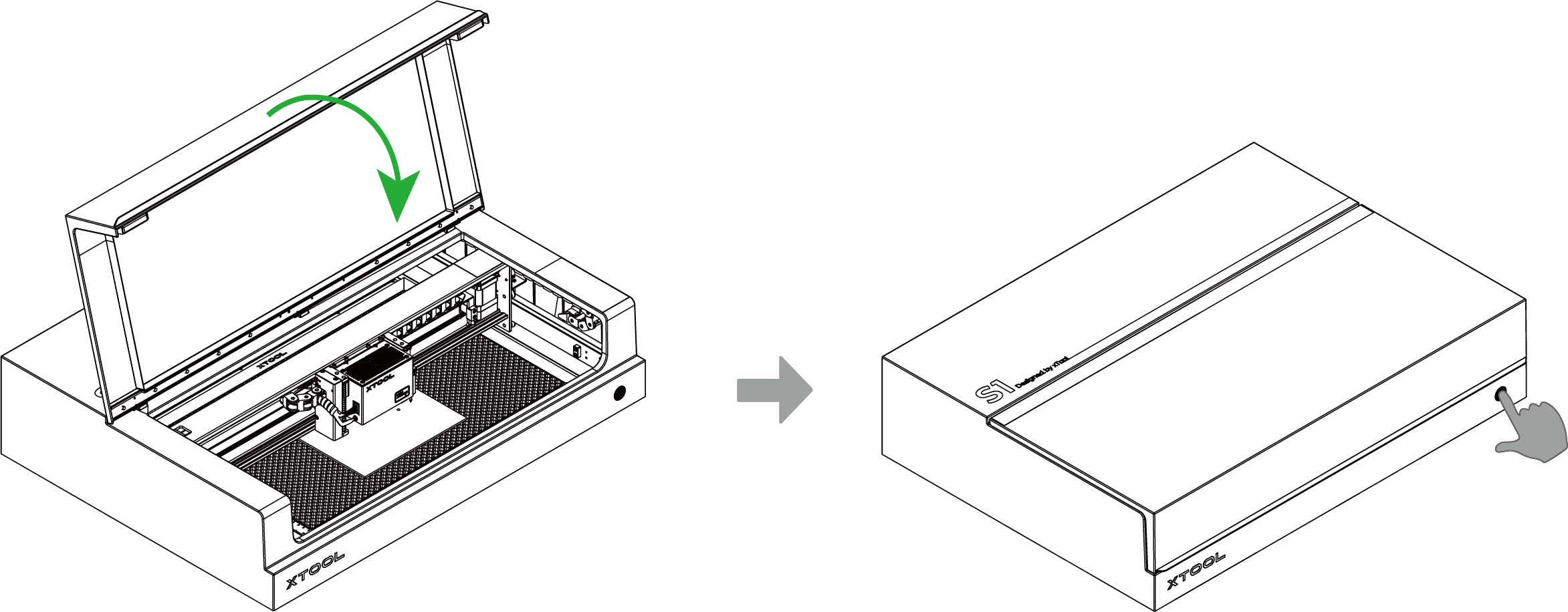

(2) Close the lid of xTool S1, and then click Framing in the software. Press the button on xTool S1 to start framing. The laser spot will move along the boundary of the processing pattern on the material so that you can preview the processing area.

(3) After you confirm that the processing area is proper, click Framing completed in XCS. If the area is not ideal, you can adjust the material position or adjust the element positions in the software, and then preview the processing area again.

8. Start processing

Note: If you use the infrared laser module at a temperature of 10 ℃ or below, please preheat the laser module for 2 minutes to ensure better processing results.

(1) On the upper right corner of the software, click Start.

(2) Preview the processing objects in the software. Then, in the upper right corner of the software, click Start.

(3) Close the lid of xTool S1. Then, press the button on xTool S1 to start processing.

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.