1. Connect xTool M1 Ultra to xTool Studio

Refer to Connect and Setup xTool M1 Ultra with xTool Studio for instructions on connecting xTool M1 Ultra to xTool Studio.

2. Install the laser module

(1) Align the slot of the laser module and the slot of the multi-function holder, slide the laser module, and install it on the multi-function holder.

(2) Push down the laser module until it sits snugly on the holder.

(3) Toggle the locking bar to lock the module.

3. Place the material

Open the lid of xTool M1 Ultra, and place the material to be processed on the baseplate.

Note: To cut a material, it is recommended to place the slatted panel on the baseplate before placing the material. The panel can reduce the burned area on the back of the material and protect the baseplate.

4. Select the processing mode and material

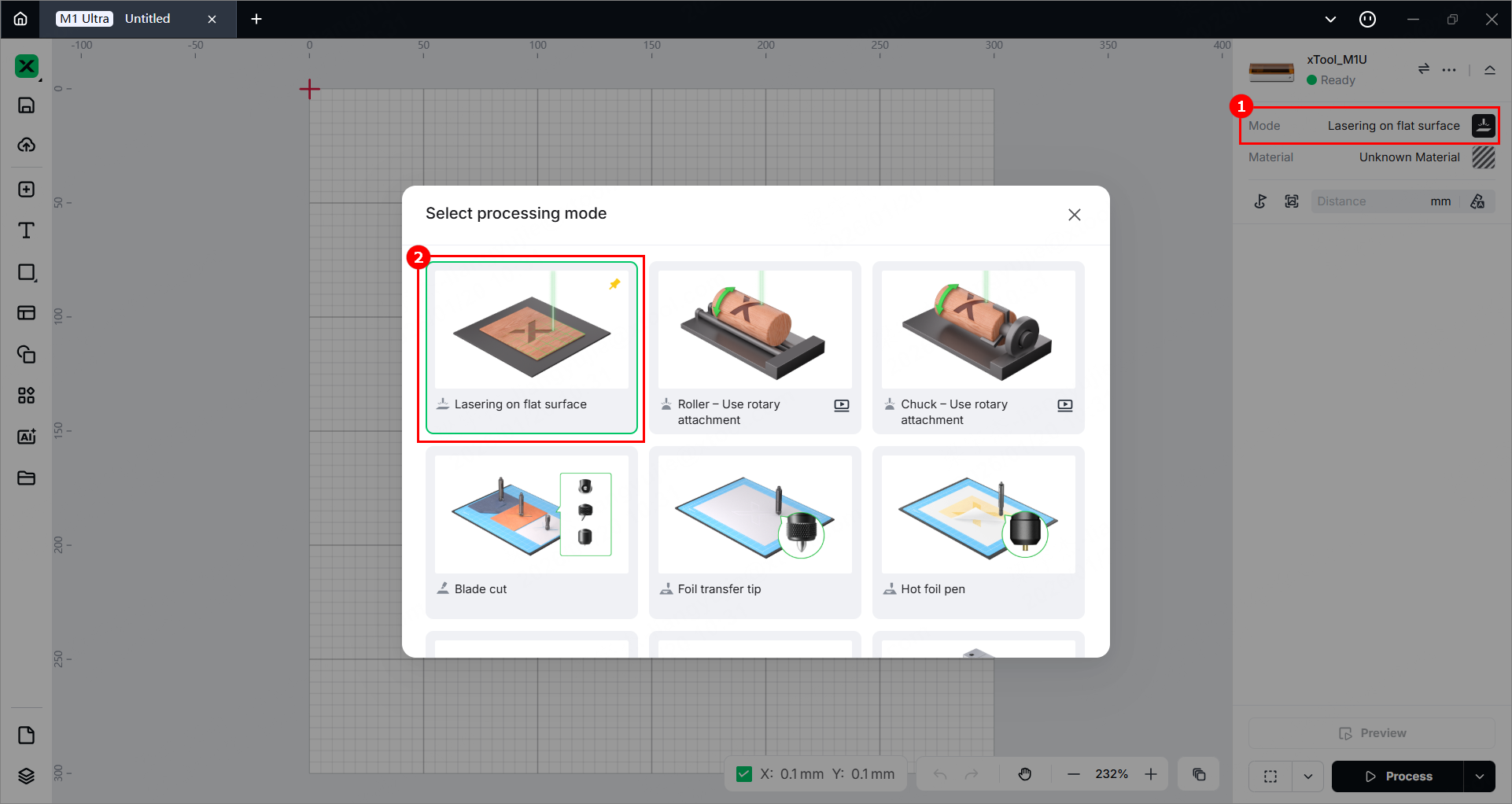

(1) In the right panel of the page, click the current processing mode, and then select Lasering on flat surface as the processing mode.

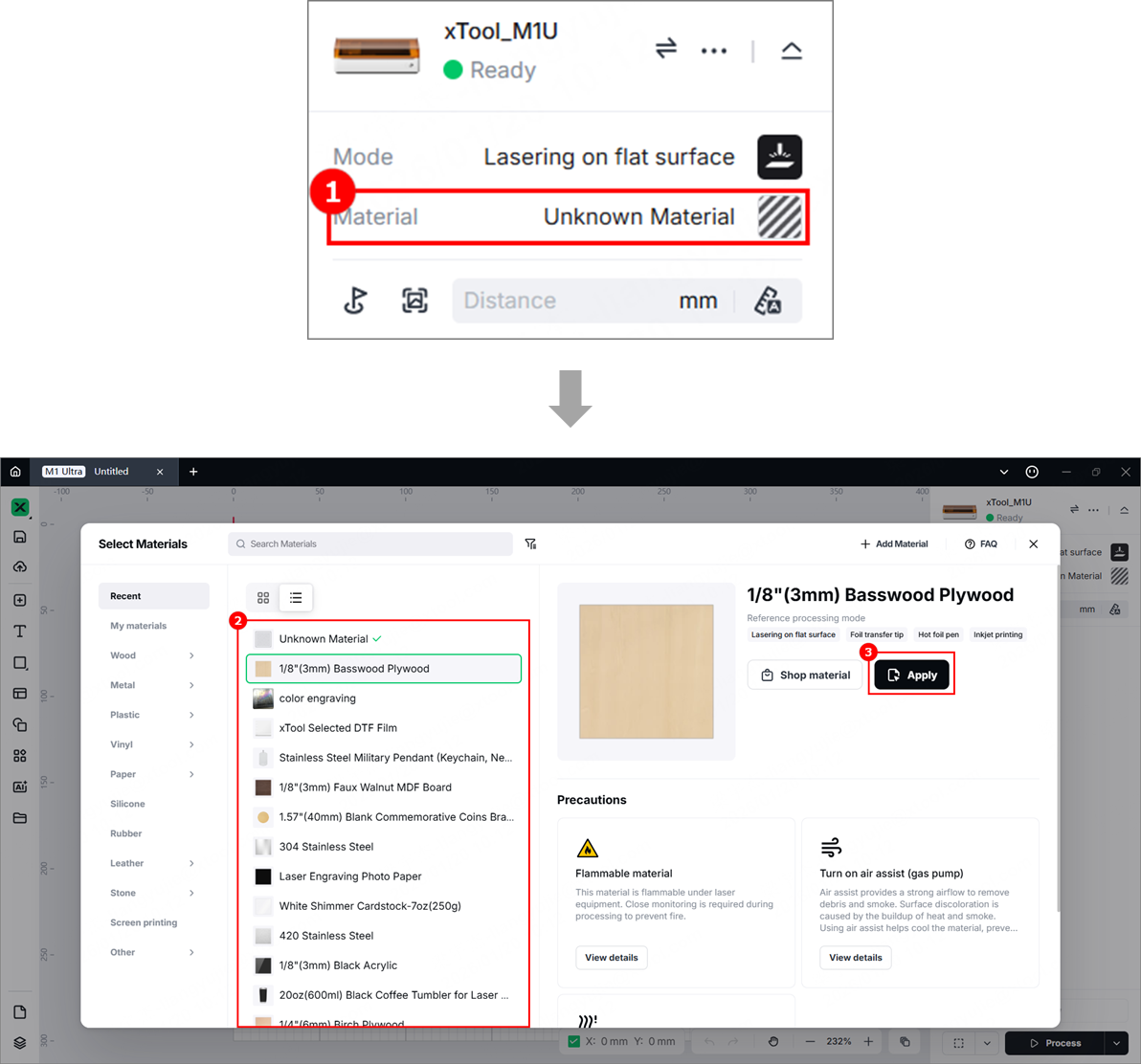

(2) Click Unknown Material, select a desired material, and click Apply.

Note: The recommended parameter settings can achieve the best results only when using xTool materials. For third-party materials, it is recommended that you conduct a material test array on your own first to obtain the desired effects and parameters. Meanwhile, make sure that the materials are free from moisture or contamination, as these factors can significantly affect processing quality.

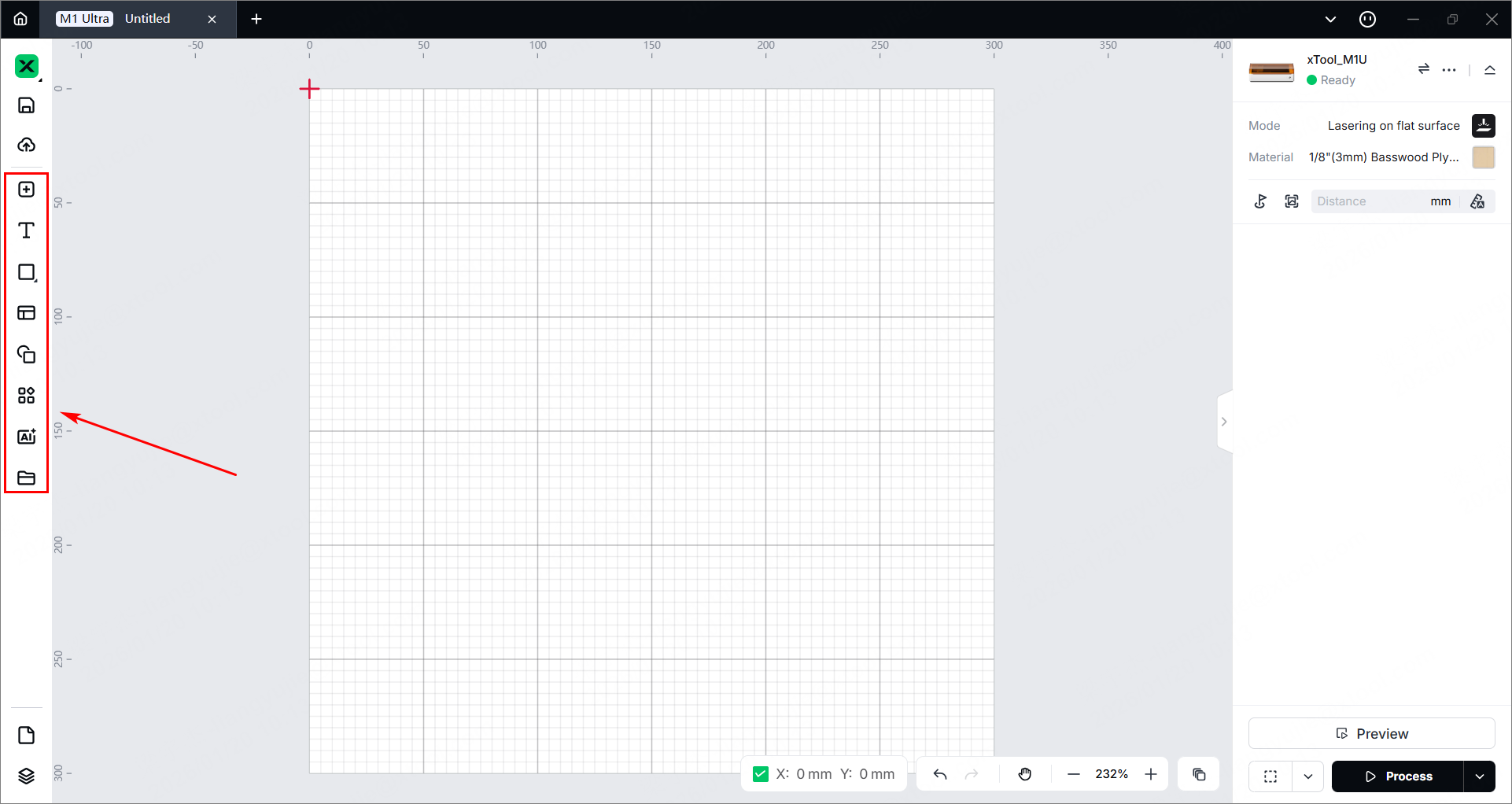

5. Design objects for processing

(1) Use the tools on the left side of the canvas to create objects. You can import images, insert shapes, enter text, or draw vector graphics.

Note: xTool Studio supports importing the following image formats: SVG, DXF, JPG, JPEG, PNG, BMP, etc.

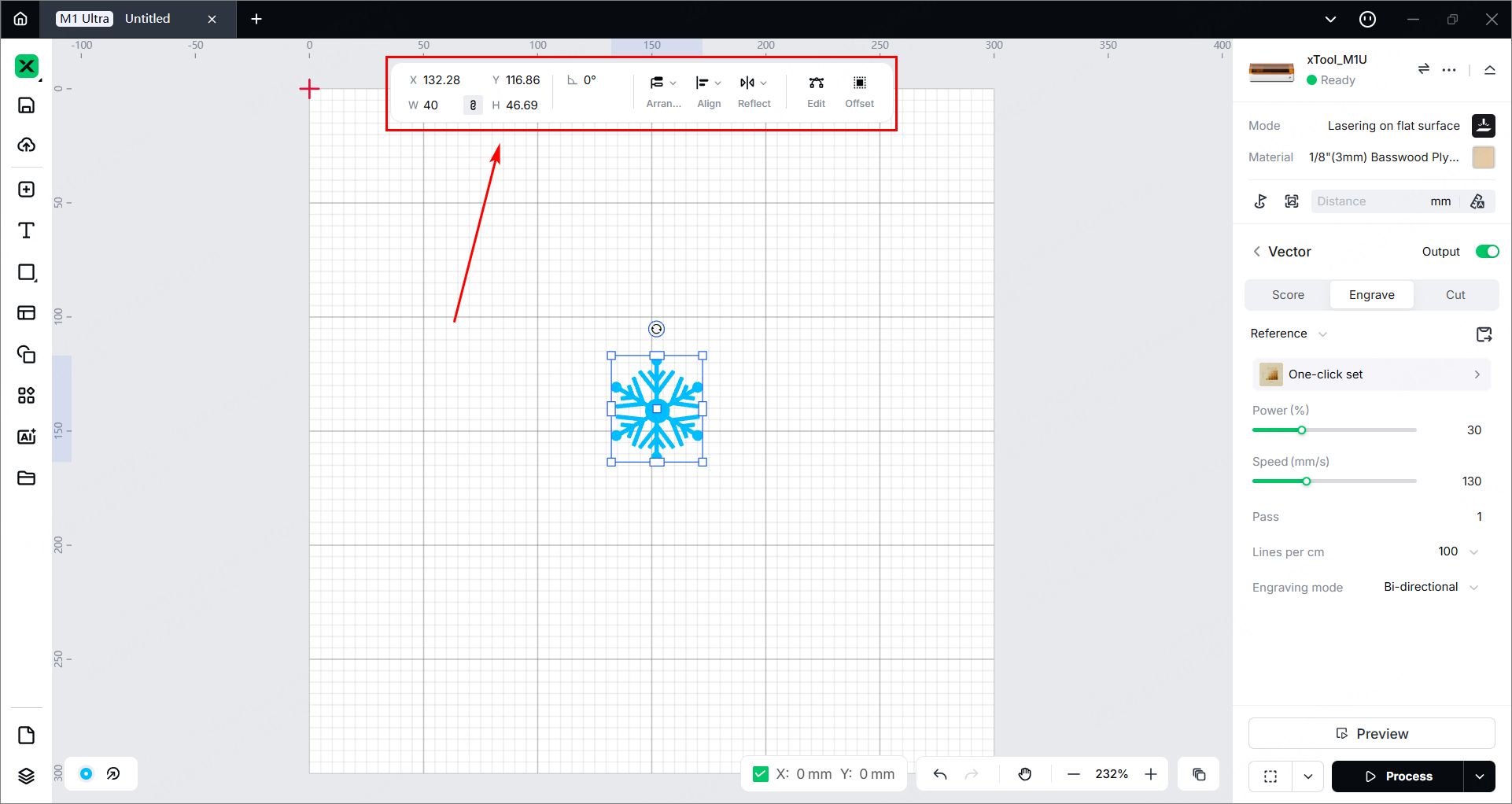

(2) You can use the tools above the canvas for further editing when selecting objects.

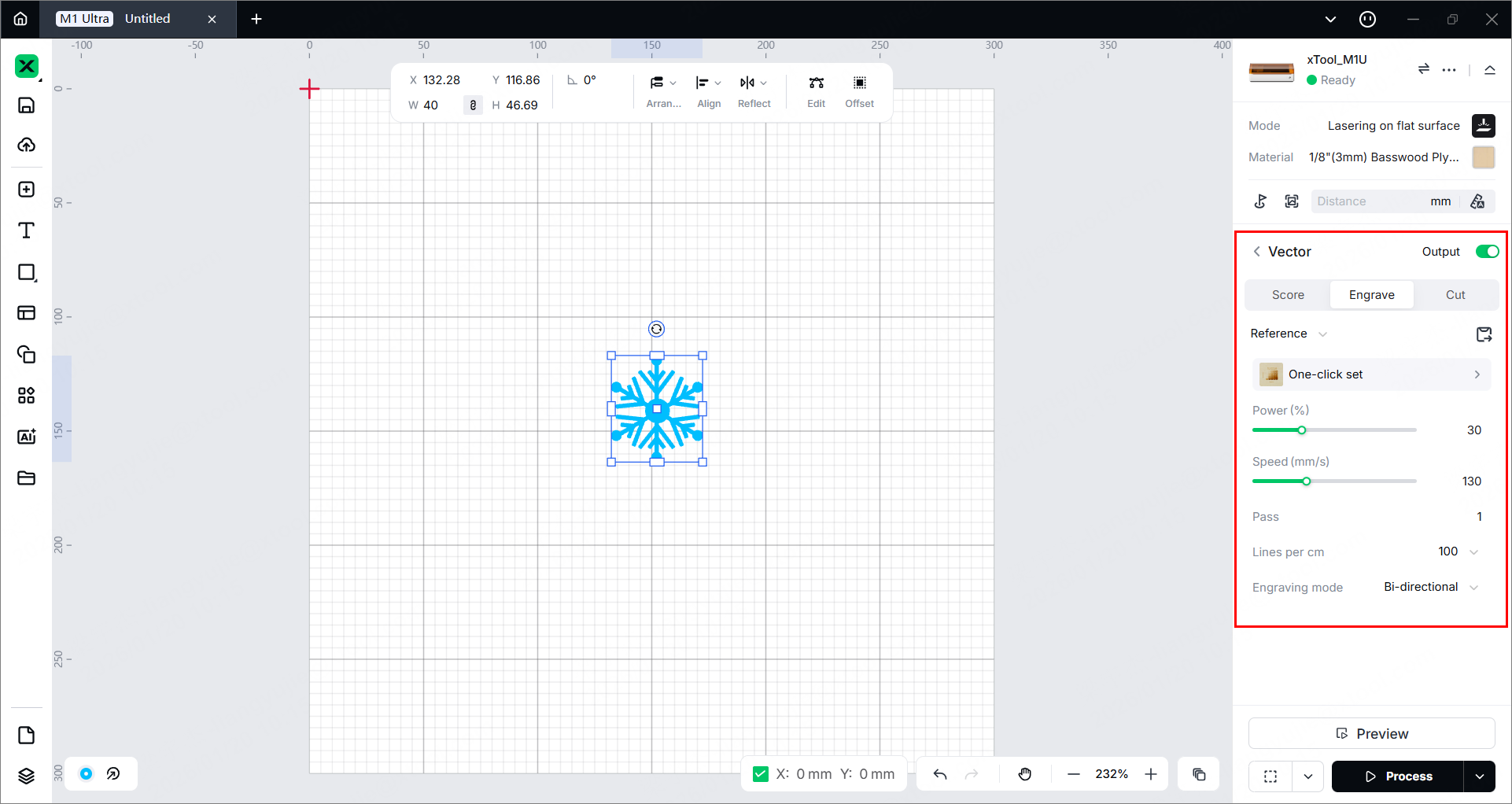

6. Set parameters for processing

Select objects on the canvas and set their parameters in the right panel.

Processing type

- Image - Engrave/C-engrave: Laser beams hit the surface of the material to change the color of the surface. By creating different shades of color on the material surface, xTool M1 Ultra prints an image on the material.

- Vector - Score: Laser beams walk along the path of the vector graphic, drawing the vector on the material with lines.

- Vector - Engrave: Laser beams walk through the entire area enclosed by the vector path, engraving the vector on the material with monochromatic fillings.

- Vector - Cut: Laser beams cut the material along the path of the vector graphic.

Note: You need to set parameters for every object. A missed object may fail to be processed.

Note:

- Parameter options vary for bitmap objects and vector objects. You can select multiple objects of the same type and set parameters for them at once.

- For more information on parameter settings, see atomm.com/easyset.

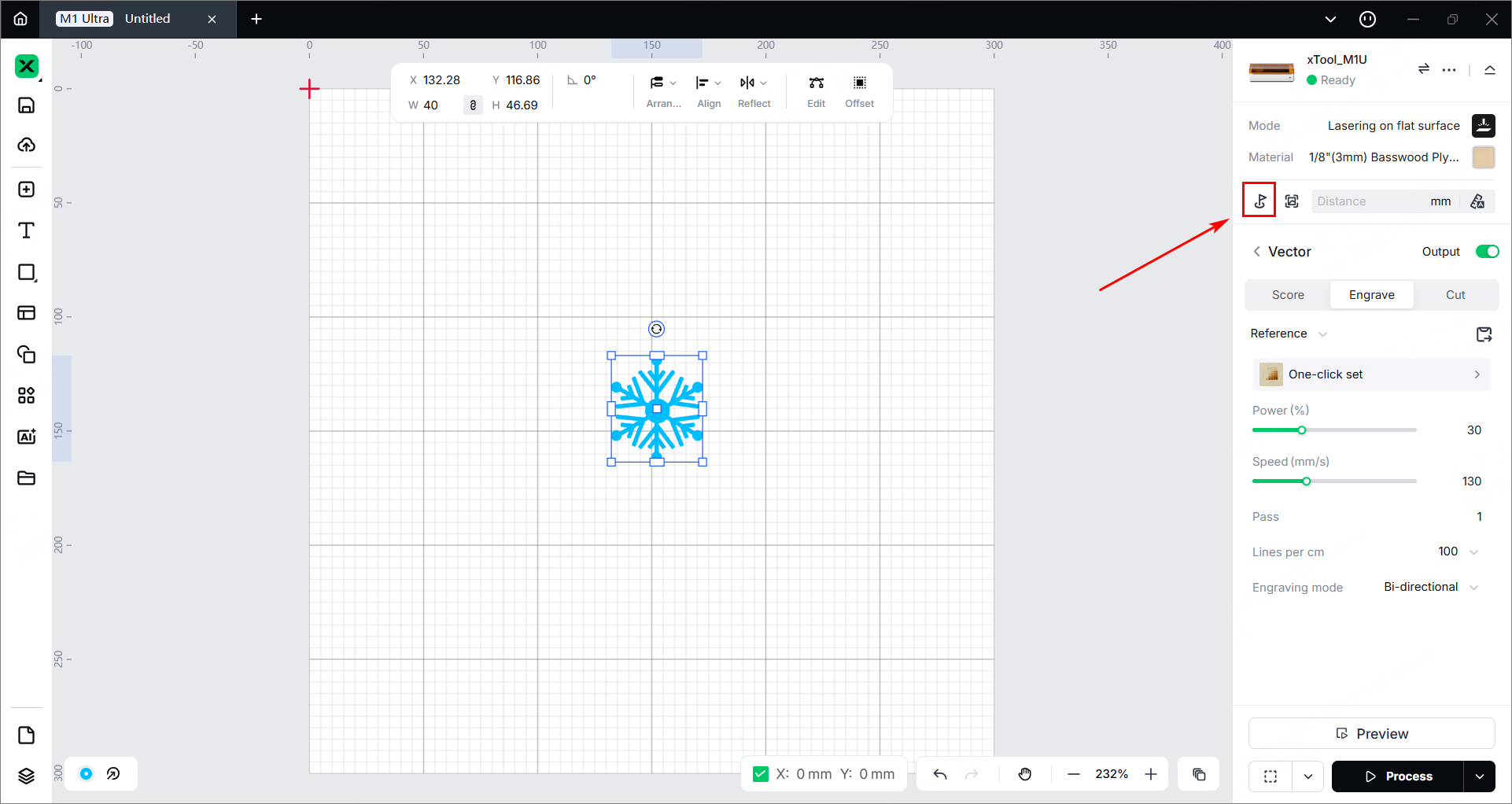

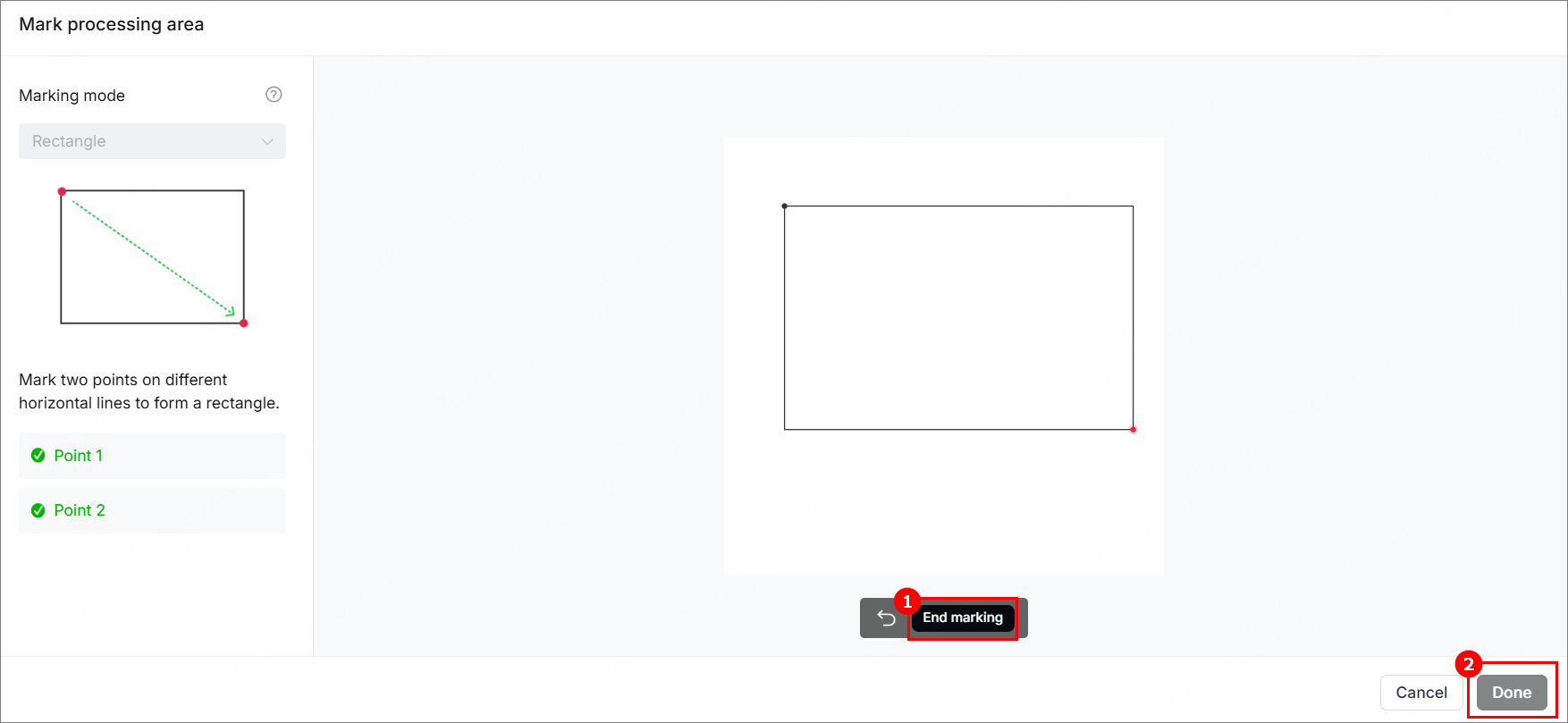

7. Mark the processing area

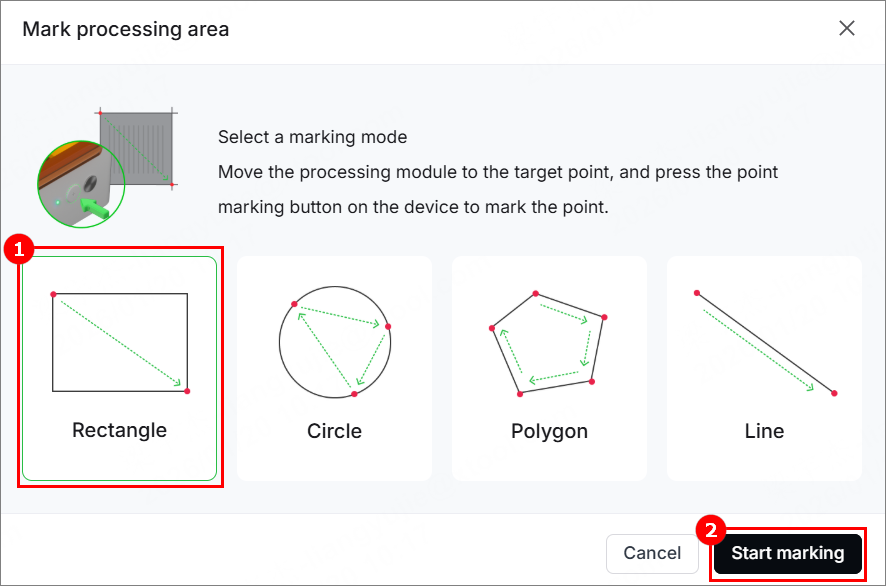

(1) In the right panel of the page, click the flag to mark the processing area.

(2) Select a marking mode based on the shape of the target processing area, and click Start marking.

(3) Manually move the laser module to make the red cross spot fall at a vertex of the target processing area, and press the Point marking button on the device to record the position. Then, repeat the same steps to record the other required vertex(es) for the target processing area.

(4) Make sure two points are marked. Click End marking > Done, and then the target processing area will be marked out on the canvas.

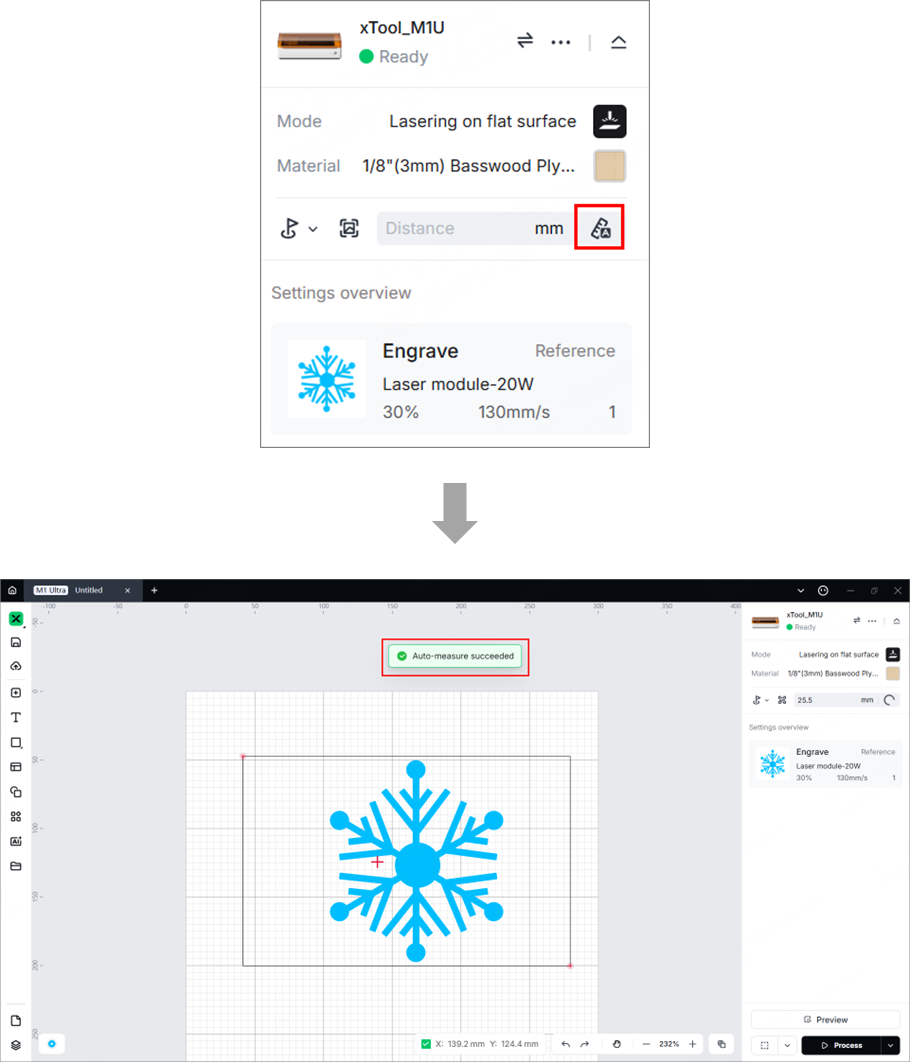

8. Measure the thickness of the material

xTool M1 Ultra can measure the distance between the laser module and the material surface automatically.

(1) Move the laser module over the material. Ensure that the red cross falls on the surface of the material. Then close the lid.

(2) In the right panel of the page, click the  icon next to the Distance parameter, and xTool M1 Ultra will automatically measure the distance from the laser module to the material surface.

icon next to the Distance parameter, and xTool M1 Ultra will automatically measure the distance from the laser module to the material surface.

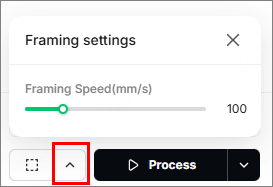

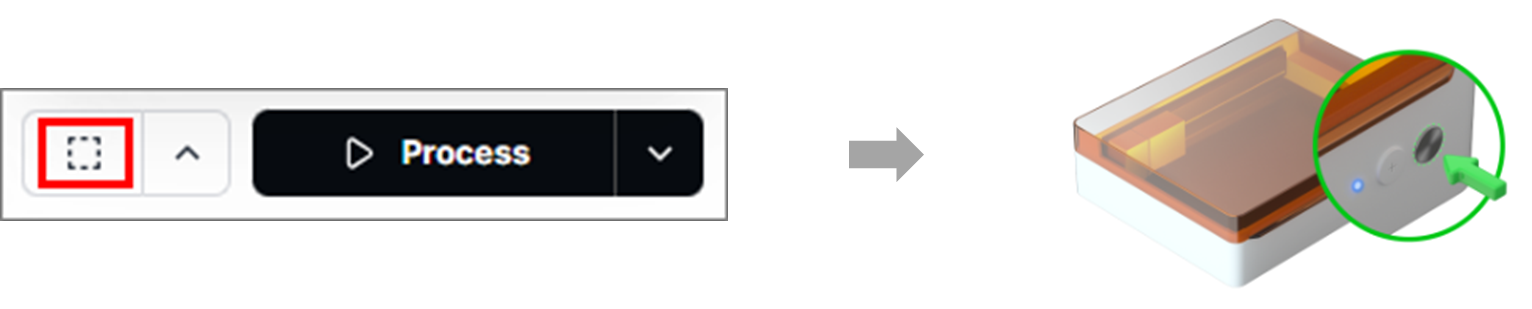

9. Preview the processing area

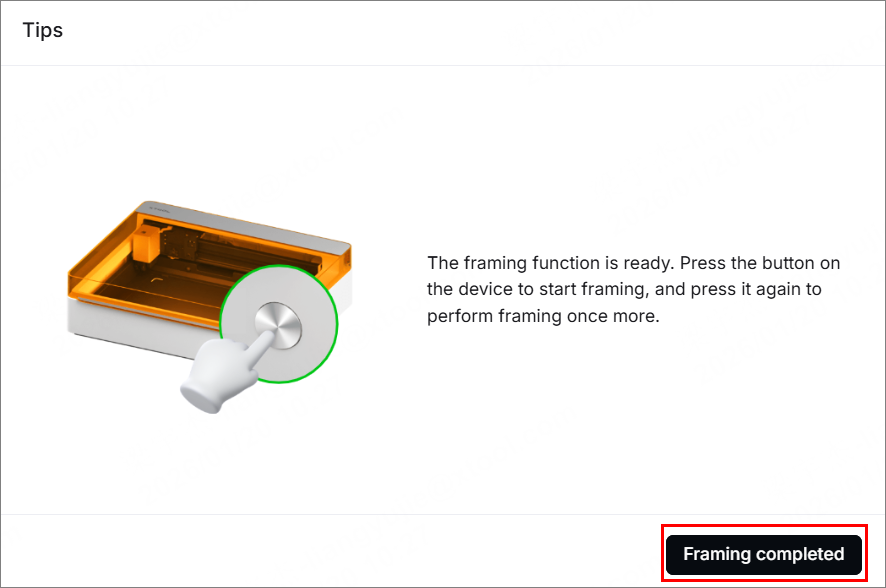

Framing means that the laser module moves along the boundary of the processed object on the material, so that the processed area on the material can be previewed. Perform the following steps to start framing.

(1) Click in the bottom-right corner of the software to set framing speed.

(2) Click  in the bottom-right corner of the software and press the framing button on xTool M1 Ultra to start framing.

in the bottom-right corner of the software and press the framing button on xTool M1 Ultra to start framing.

(3) After confirming the processing area is proper, click Framing completed in xTool Studio.

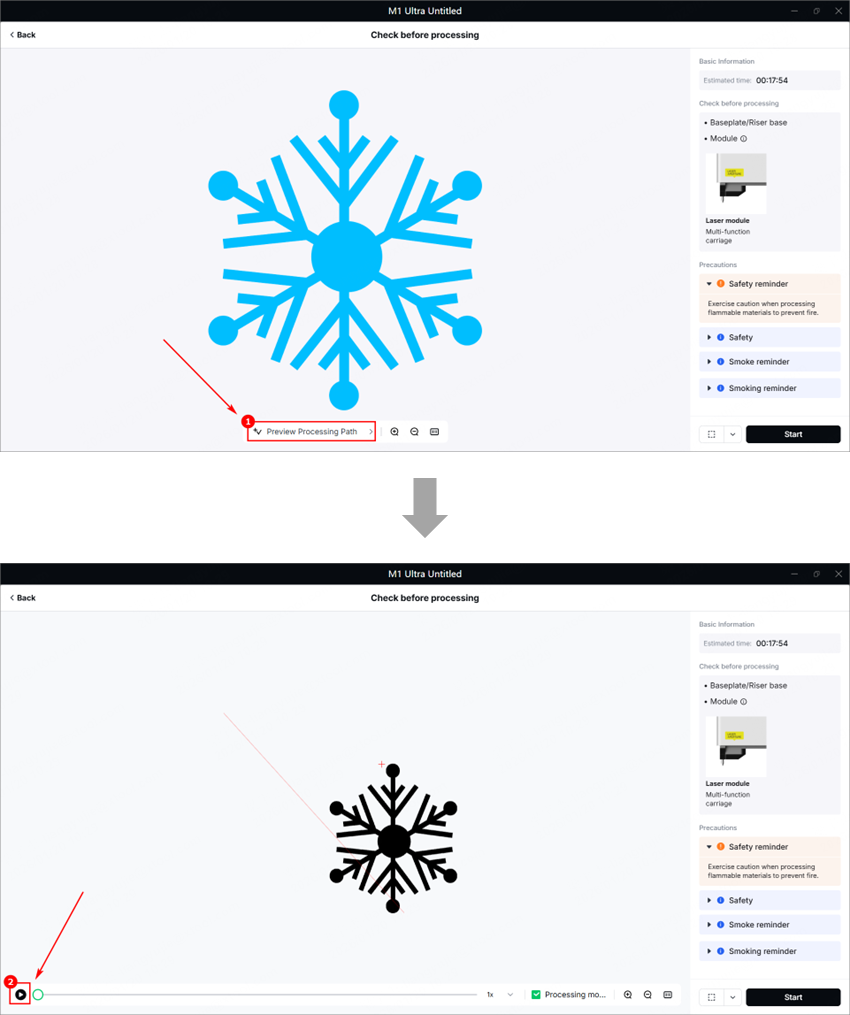

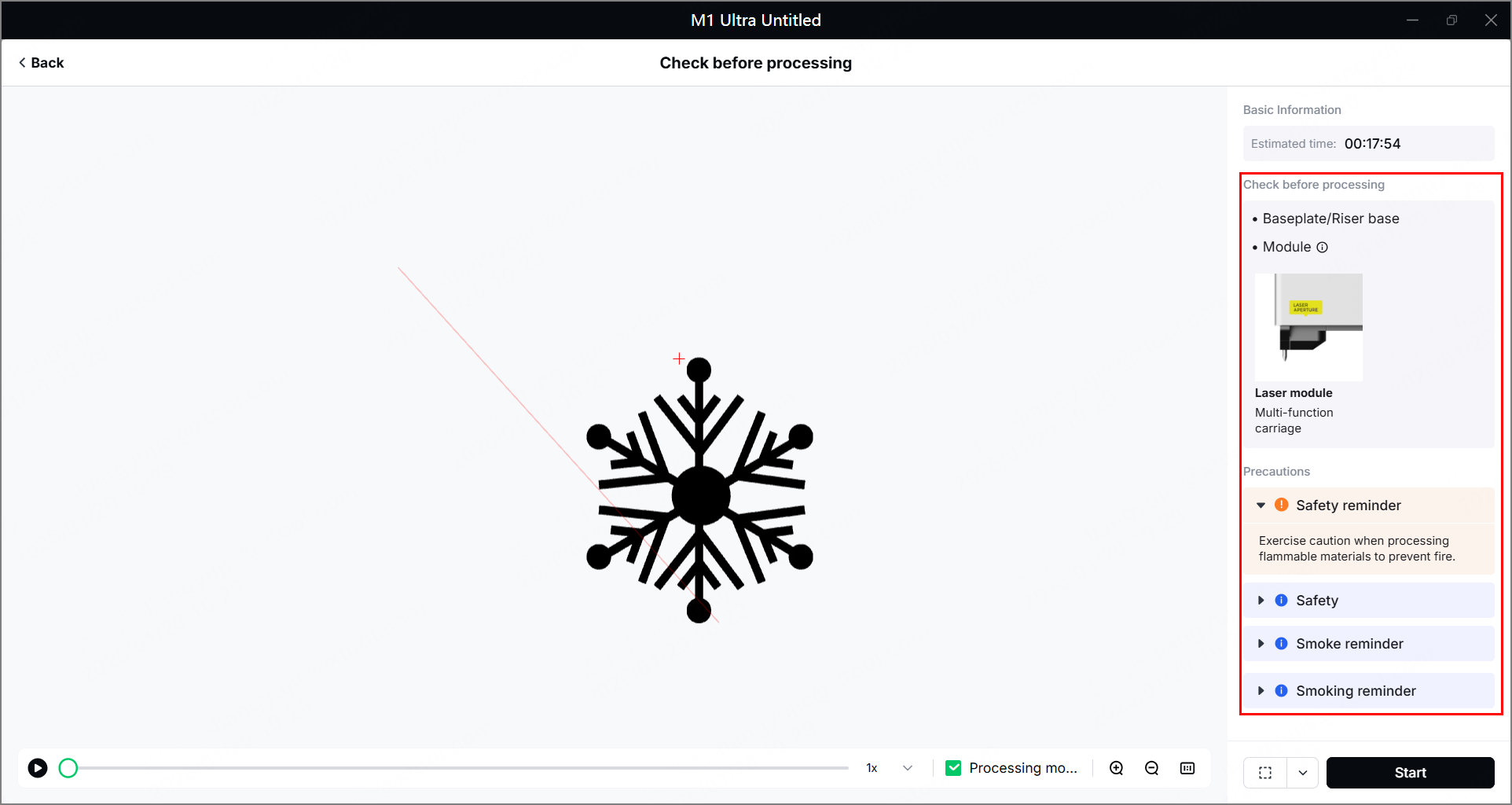

10. Start processing

(1) In the bottom-right corner of the page, click Process.

(2) Click Preview Processing Path and .

(3) Check whether the accessories or modules are prepared before processing on the right list and read the safety precautions.

(4) In the bottom-right corner of the software, click Start.

(5) When the software shows Ready, press the button on xTool M1 Ultra to start processing.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.