xTool Studio is an all-in-one software for graphic designing and editing, laser process setting, and device controlling.

Minimum and recommended PC requirements

Item | Minimum configuration | Recommended configuration |

|---|---|---|

Processor | Intel Core i5-6200U | Intel Core i5-11600 |

Operating system | Win 10 (64 bit) macOS 11 or later | |

RAM | 8 GB | 16 GB or more |

Display resolution | 1280 × 720 (pixels) | 1920 × 1080 (pixels) or higher |

Hard drive | 8 GB | 12 GB or more |

- With the minimum configurations, all the functions of xTool Studio can be used properly. When you import a complex image, such as an image larger than 50,000,000 pixels or an SVG image larger than 1 MB, however, xTool Studio may fail to run smoothly.

- With the recommended configurations, xTool Studio can run more smoothly when you import and edit a complex image; the software delay may be shorter, and the performance is better.

Download and install xTool Studio

(1) Download xTool Studio from xtool.com/pages/software.

(2) Double-click the software you've downloaded to install it.

(3) Open xTool Studio. In the top-right corner, click the icon > Settings, and set the language on the General tab page.

Connect xTool M1 Ultra to xTool Studio

USB connection

(1) Use the USB cable to connect xTool M1 Ultra to your computer.

Note: If the provided USB cable is incompatible with your computer, you need to use an adapter, which is not included in the pack.

(2) Open xTool Studio on your computer. In the top-right corner of the software, click + New Project.

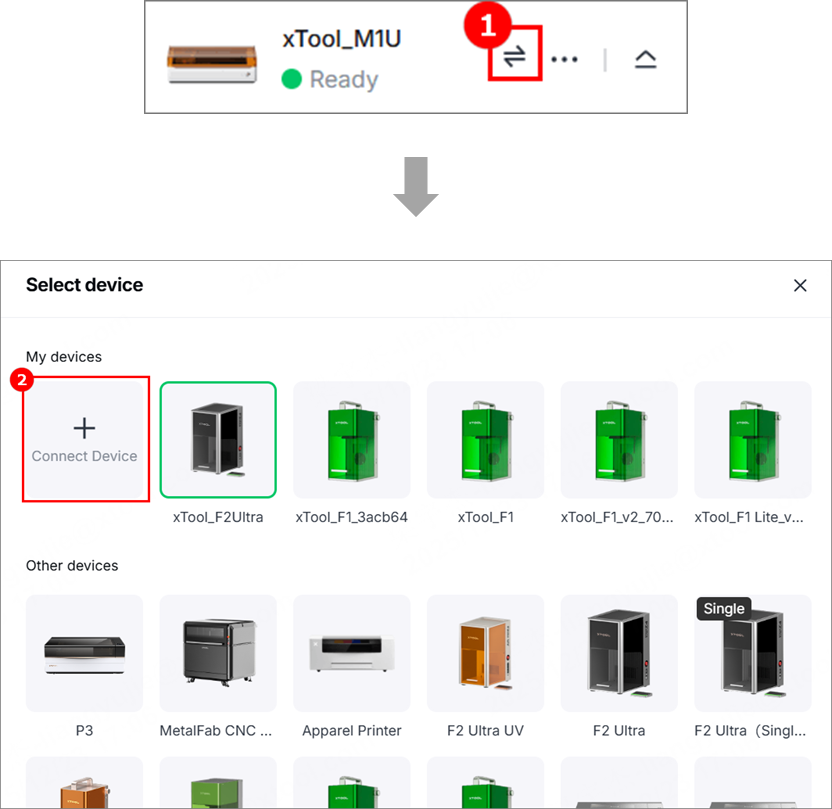

(3) On the right side of the page, click Select device.

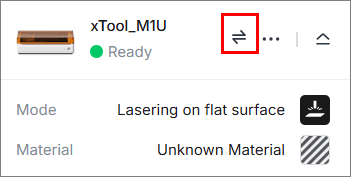

Note: If you have connected an xTool device in xTool Studio before, click the icon next to the device.

(4) On the pop-up window, click Add Device. Then, click the name of your device to connect to it.

Note: After the device is connected, you can configure Wi-Fi for it so that you can connect it to xTool Studio through Wi-Fi next time.

Wi-Fi connection

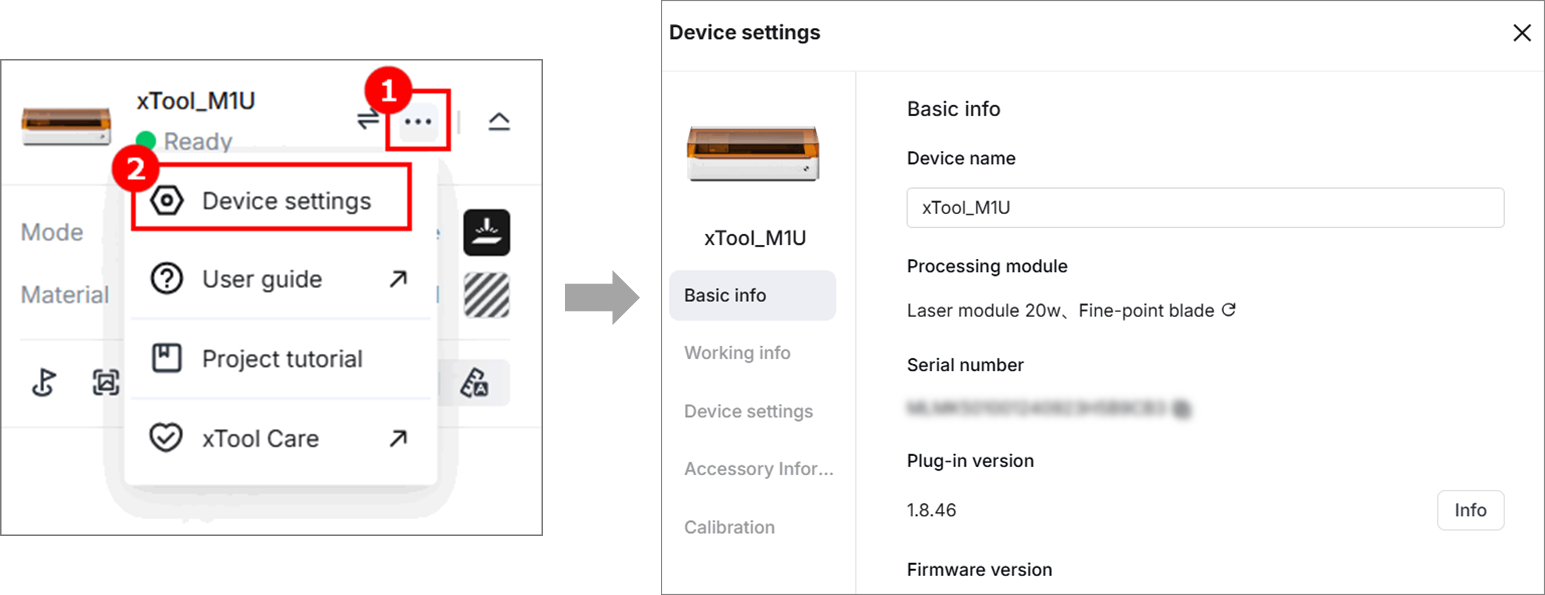

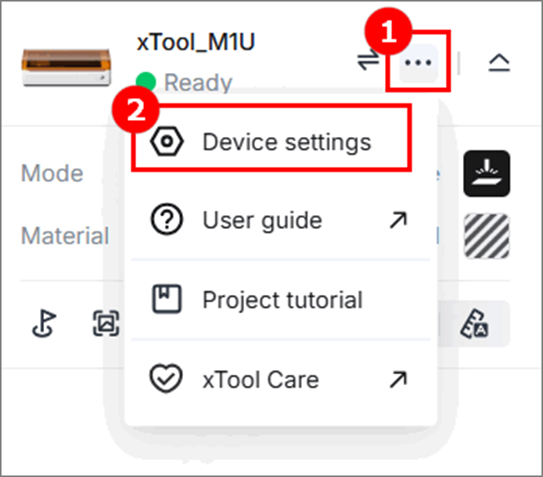

(1) In the top-right corner of the software, click > Device settings to enter the device settings page.

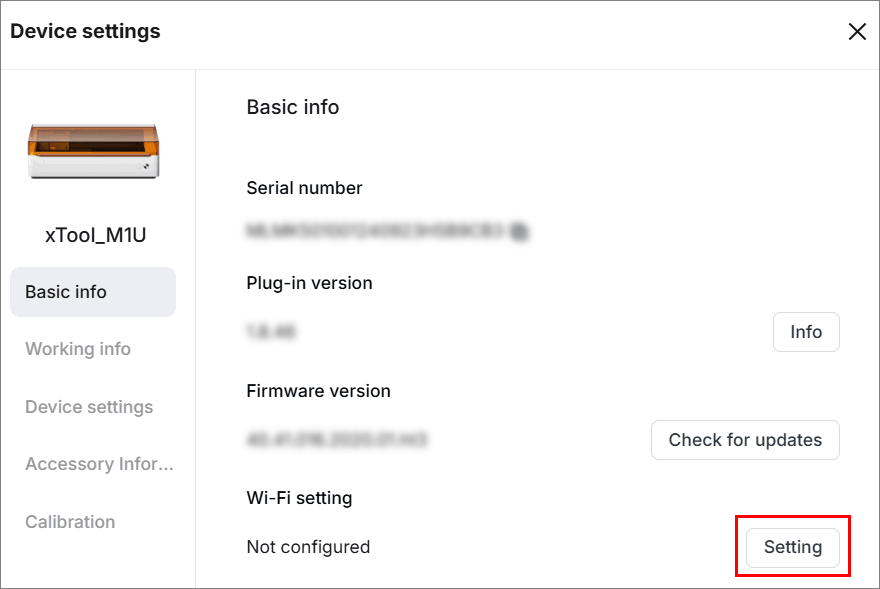

(2) On the Basic info tab page, click Setting for Wi-Fi setting.

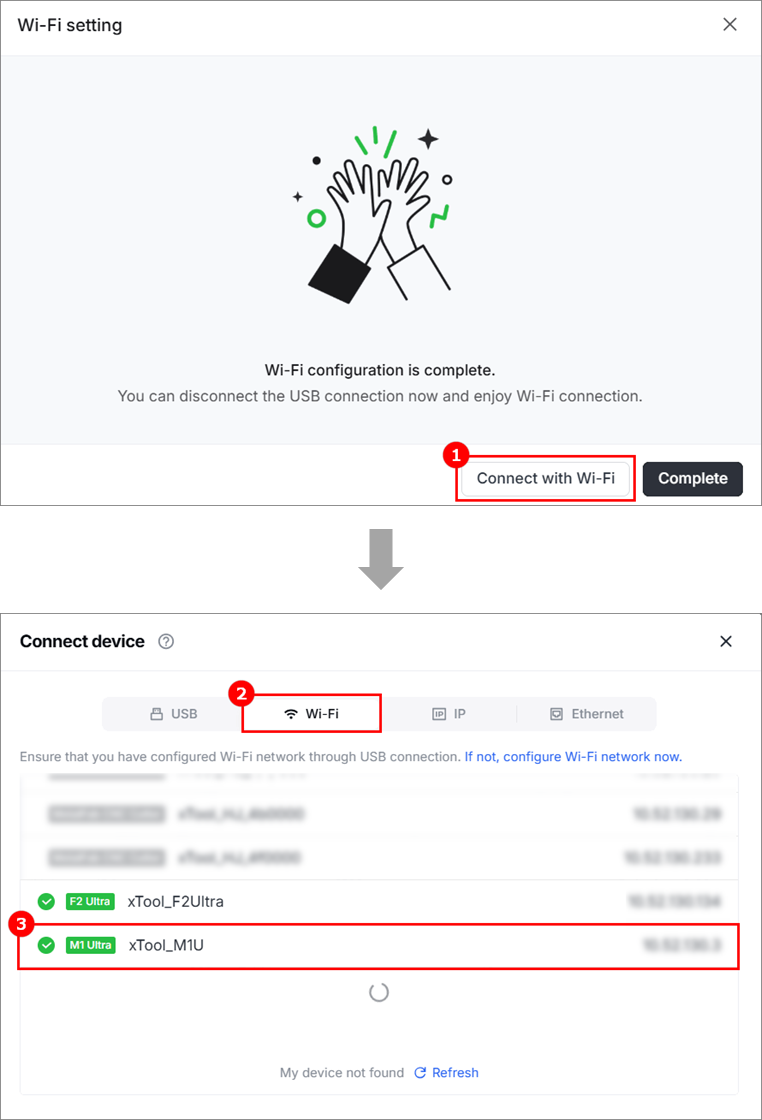

(3) In the Wi-Fi setting dialog box, select a Wi-Fi, enter the password, and click Next.

(4) Click Connect with Wi-Fi. In the Connect device dialog box, click Wi-Fi and select the device name to connect to it. If you do not want to connect your device and the computer through Wi-Fi now, click Complete to close the dialog box.

Note: Ensure that your computer and xTool M1 Ultra are connected to the same network.

IP address connection

After you complete the Wi-Fi settings for xTool M1 Ultra, an IP address is displayed under Wi-Fi setting on the device settings page. You can use the IP address to connect xTool M1 Ultra to the computer.

(1) In the top-right corner of the software, click > Device settings to enter the device settings page.

(2) Note down the IP address and return to the canvas page.

(3) On the canvas page, click > Connect Device.

(4) In the Connect device dialog box, click IP, enter the IP address noted down in step (2), and click Connect.

Set up xTool M1 Ultra in xTool Studio

(1) In the top-right corner of the software, click the icon > Device settings to enter the device settings page.

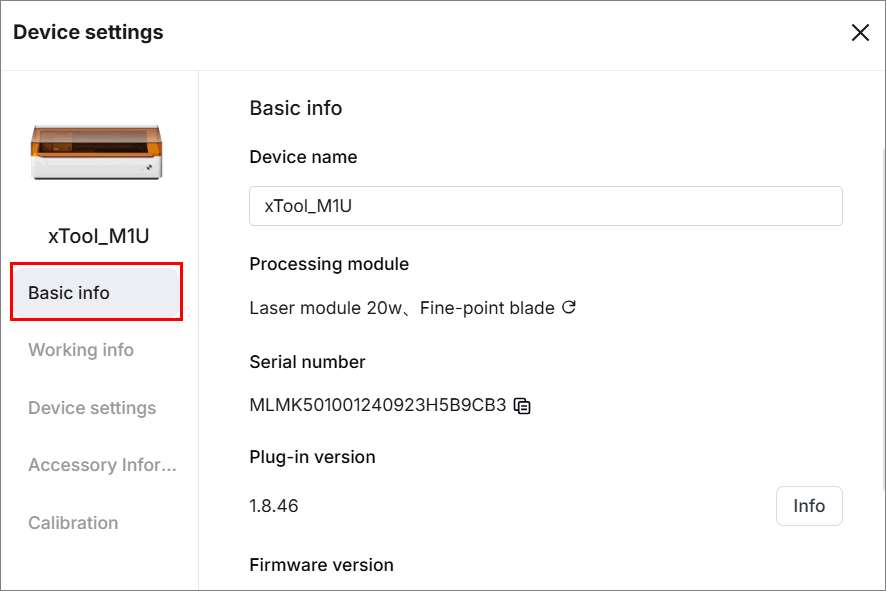

(2) In the Basic info tab page, you can view the basic information of xTool M1 Ultra and modify the following information.

- Device name: Displays the name of the device. You can set a new name for it.

- Processing module: Displays the processing modules or accessories that you are using.

- Serial number: Displays the serial number of the device.

- Plug-in version: Displays the plug-in version of the device. You can click Info to view detailed information.

- Firmware version: Displays the firmware version of the device. You can click Check for updates and update the firmware if a new version is available.

- Wi-Fi setting: Connect the device to a Wi-Fi network.

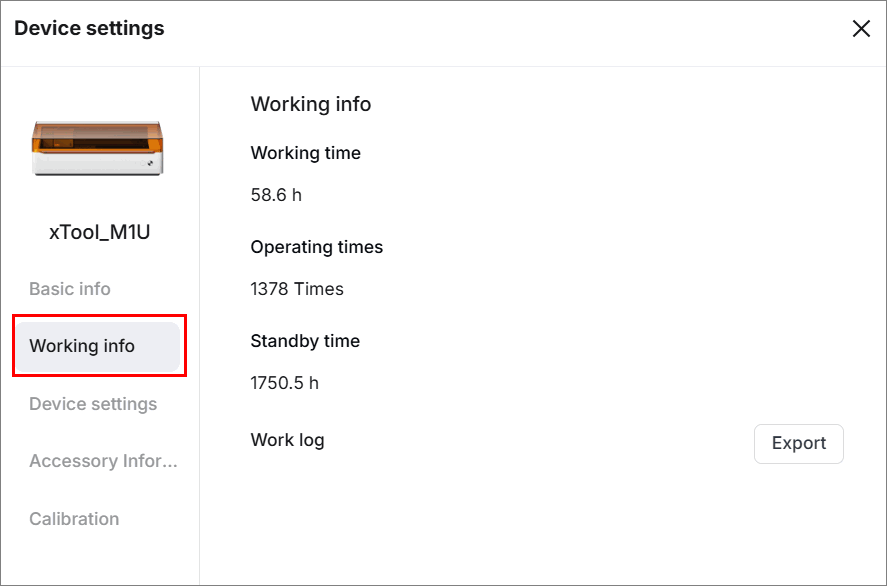

(3) In the Working info tab page, you can see the working information of the device and export the work log.

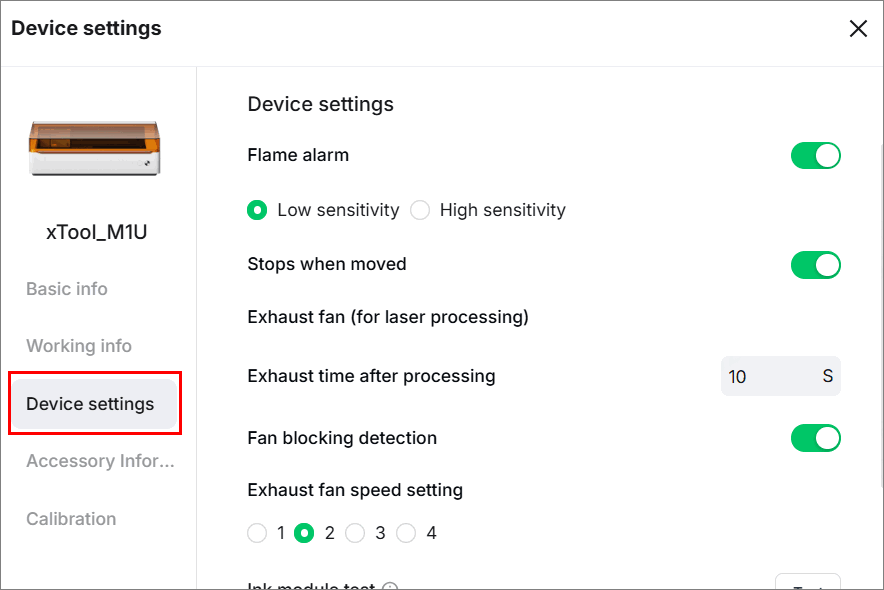

(4) In the Device settings tab page, you can set up the device.

- Flame alarm: If enabled, the device will pause processing and raise the alarm when flame is detected. You can switch between high detection sensitivity and low detection sensitivity.

- Stops when moved: If enabled, the device will pause processing when it is moved or tilted during processing. If you plan to perform laser processing on sloped surfaces while hand‑holding the device, disable this feature to ensure normal operation.

- Exhaust time after processing: You can set the time duration the exhaust fan continues to work after a processing task ends. By working for a longer time, the fan can exhaust the remaining smoke after processing.

- Exhaust fan speed setting: Sets the speed of the smoke exhaust module.

- Ink module test: Tests the ink module before processing with inkjet printing because the ink module gets blocked easily.

- Fill light brightness: Adjusts the brightness of the fill light in the working area.

- Buzzer: If enabled, the buzzer sounds when the device is ready for processing, and the processing is complete.

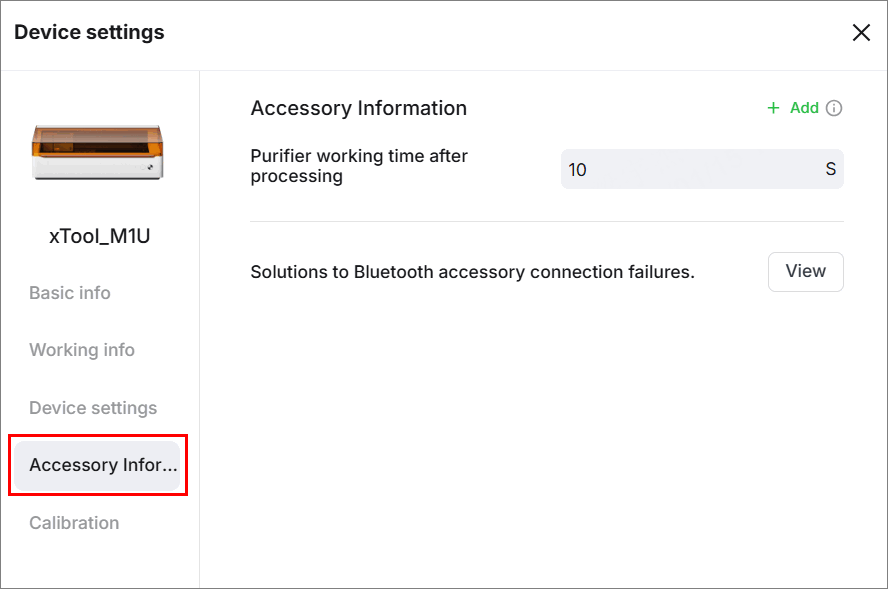

(5) In the Accessory Information tab page, you can see the information about accessories connected to xTool M1 Ultra and set parameters.

- Purifier working time after processing: You can set the time duration the smoke purifier continues to work after a processing task ends. By working for a longer time, the smoke purifier can exhaust the remaining smoke after processing.

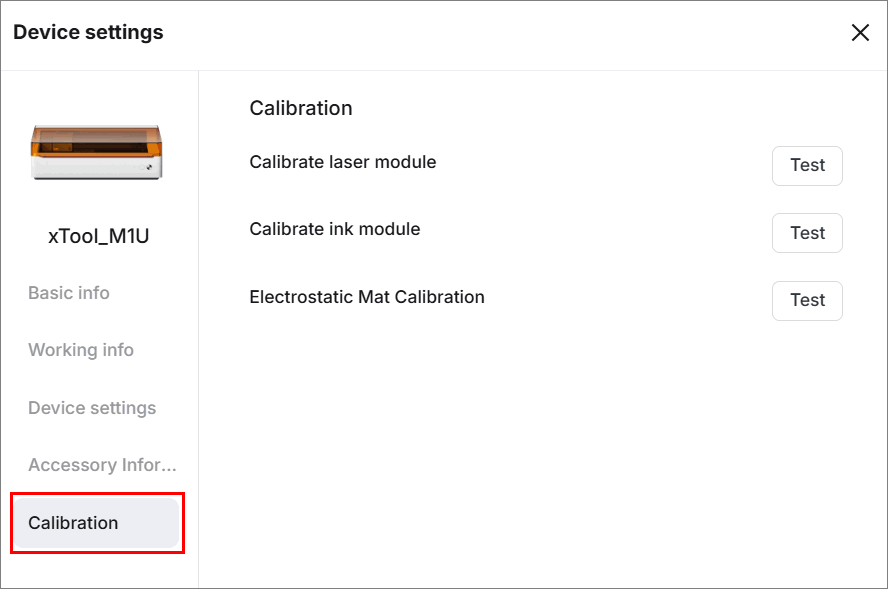

(6) In the Calibration tab page, you can calibrate the laser module and ink module as needed.

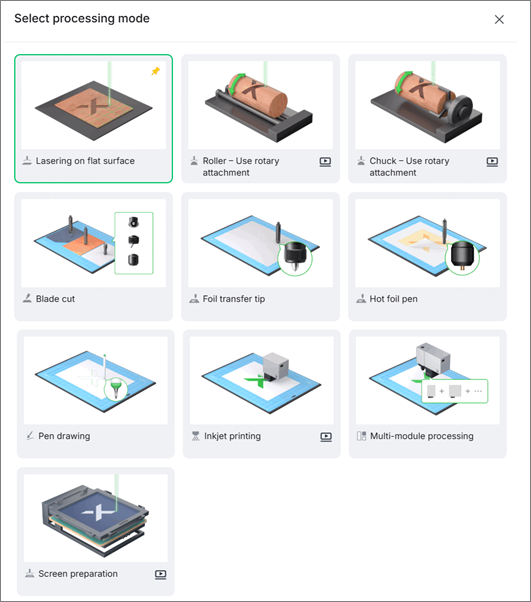

Processing modes of xTool M1 Ultra

xTool Studio supports multiple processing modes for xTool M1 Ultra.

- Lasering on flat surface: processes flat materials by using laser beams. With this function, you can engrave or cut common flat materials, such as wooden boards, coasters, dark acrylic, and metal sheets.

Processing material size | 300 mm * 300 mm |

Maximum processing thickness | 25 mm |

If the baseplate is required | Yes |

If the honeycomb panel is required | No |

Supported processing modes | Score Engrave Cut |

Supported image types | Vector Bitmap |

- Use rotaty attachment: processes cylindrical materials by using laser beams. To use this mode, you need to use xTool M1 Ultra with Rotary Attachment and the riser base.

Processing material size | 300 mm * 300 mm |

Focusing range (initial position of the baseplate is 0) | 0 mm – 25 mm |

If the baseplate is required | No |

If the honeycomb panel is required | Optional |

Supported processing modes | Score Engrave |

Supported image types | Vector Bitmap |

- Blade cut: processes materials by using the cutting blade, rotary blade, and fine-point blade. Note that when using this function, a cutting mat is required to protect the baseplate of xTool M1 Ultra.

Processing material size | Fine-point blade & Rotary blade: 300 mm * 300 mm Cutting blade: 295 mm * 295 mm |

Maximum processing thickness | Cutting blade & Rotary blade: 2.5 mm Fine-point blade: 1.5 mm |

Blade pressure | Cutting blade: 45 g – 500 g Rotary blade: 45 g – 2800 g Fine-point blade: 35 g – 600 g |

Processing materials | Cutting blade: leather/melt Rotary blade: denim/fabrics Fine-point blade: paper/PVC/thin leather/PU film |

If the baseplate is required | Yes |

If the honeycomb panel is required | No |

Supported processing modes | Blade cut |

Supported image types | Vector |

- Foil transfer tip: processes materials by using 3 sizes of the foil transfer tip (The bold and thin tips are sold separately). With this function, you can process foil transfer or card stock.

Processing material size | 300 mm * 300 mm |

Maximum processing thickness | 3 mm |

Tip pressure | Line transfer & Fill transfer: 45 g – 600 g |

Tip size | Bold/regular/thin |

If the baseplate is required | Yes |

If the honeycomb panel is required | No |

Supported processing modes | Foil transfer tip |

Supported image types | Vector |

- Hot foil tip:

Processing material size | 300 mm * 300 mm |

Maximum processing thickness | 25 mm |

Tip pressure | Line transfer & Fill transfer: 35 g – 425 g |

Tip size | Bold/regular/thin |

If the baseplate is required | Yes |

If the honeycomb panel is required | No |

Supported processing modes | Hot foil tip |

Supported image types | Vector |

- Pen drawing: draws patterns on paper or card stock by using multiple colors of the fine-point pen.

Processing material size | 300 mm * 300 mm |

Maximum processing thickness | 1 mm |

Blade pressure | Line drawing & Color filling: 35 g – 425 g |

Pen tip size | 0.4 mm |

If the baseplate is required | Yes |

If the honeycomb panel is required | No |

Supported processing modes | Drawing pen |

Supported image types | Vector |

- Inkjet printing: processes printing on paper or wooden board by the ink module.

Processing material size | 294 mm * 298 mm |

Maximum processing thickness | 20 mm |

Intensity | 10% – 100% |

If the baseplate is required | Yes |

If the honeycomb panel is required | No |

Supported processing modes | Inkjet printing |

Supported image types | Bitmap |

- Multi-module processing: processes materials by multiple modules or accessories, such as the laser module with fine-point blade or ink module with laser module.

- Screen preparation: the screen preparation mode is developed for xTool Screen Printer, used to engrave screens for printing.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.