Preparations

1. Connect the conveyor to xTool F2 Ultra UV

(1) Install fastening piece D on the conveyor

(2) Install fastening piece C on xTool F2 Ultra UV

(3) Secure the conveyor on xTool F2 Ultra UV

(4) Connect the conveyor to xTool F2 Ultra UV using the connection cable

2. Connect the touchscreen controller to xTool F2 Ultra UV

3. Connect xTool F2 Ultra UV in xTool Studio

(1) Use the USB cable to connect xTool F2 Ultra UV to your computer.

(2) Open xTool Studio on your computer. On the top-right corner of xTool Studio, click + New Project.

(3) On the top-right corner of the project editing page, click to connect/switch device.

(4) On the pop-up window, click + Add Device.

(5) On the pop-up window, click the name of your device to connect to it.

(6) If you need to switch the device, click Switch on the pop-up window.

4. Ensure that the field lens in xTool F2 Ultra UV is the surface engraving lens

Check whether the field lens in xTool F2 Ultra UV is the surface engraving lens. If the inner engraving lens is installed, remove it and replace it with the surface engraving lens. Otherwise, xTool F2 Ultra UV cannot process materials when used with the conveyor.

Process materials in batches with different designs

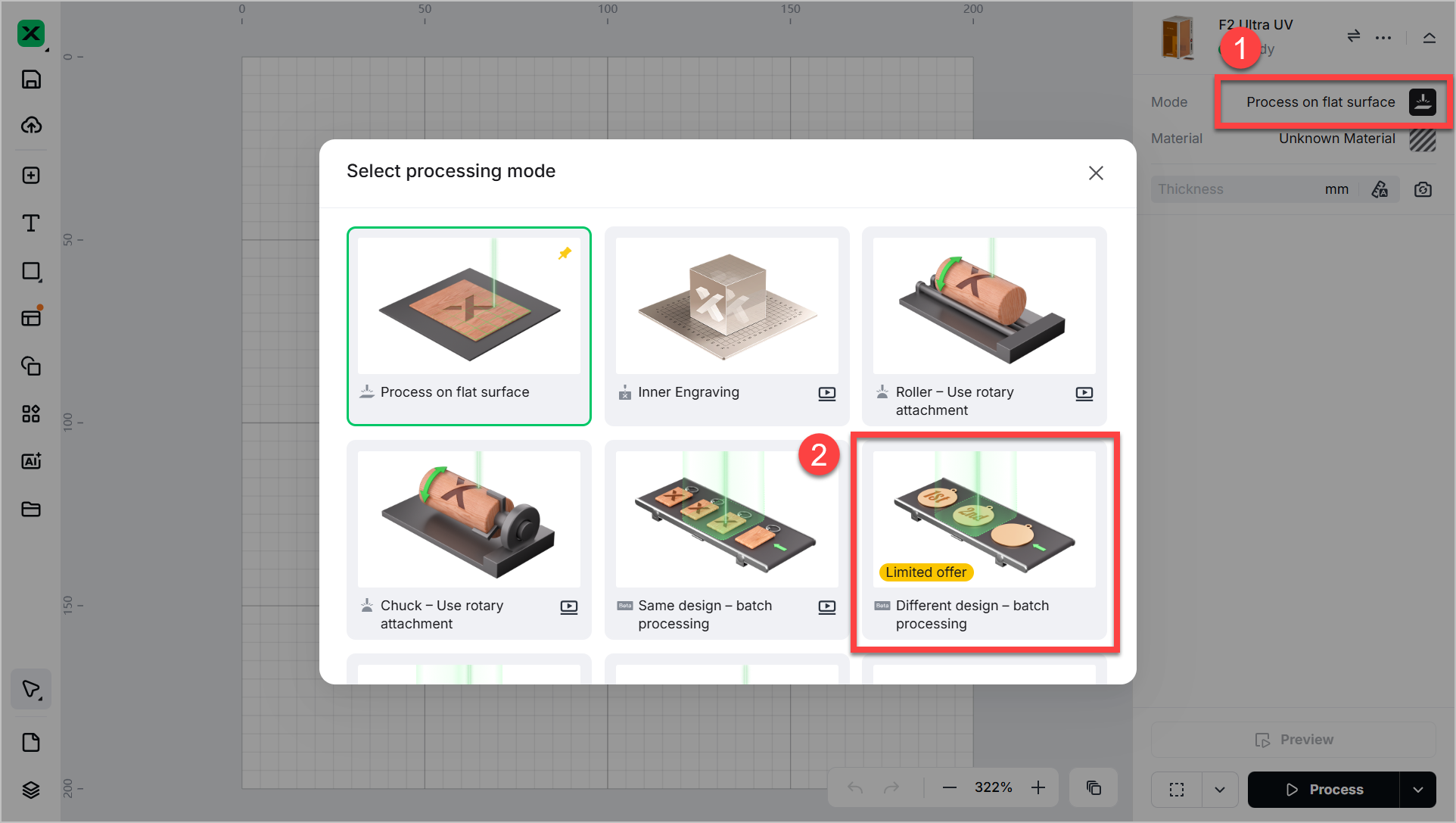

1. Select the processing mode

In the top-right corner, click the name of the current processing mode, and then select Different design - batch processing as the processing mode.

Note: If a Batch design window appears, close it and proceed to the next step.

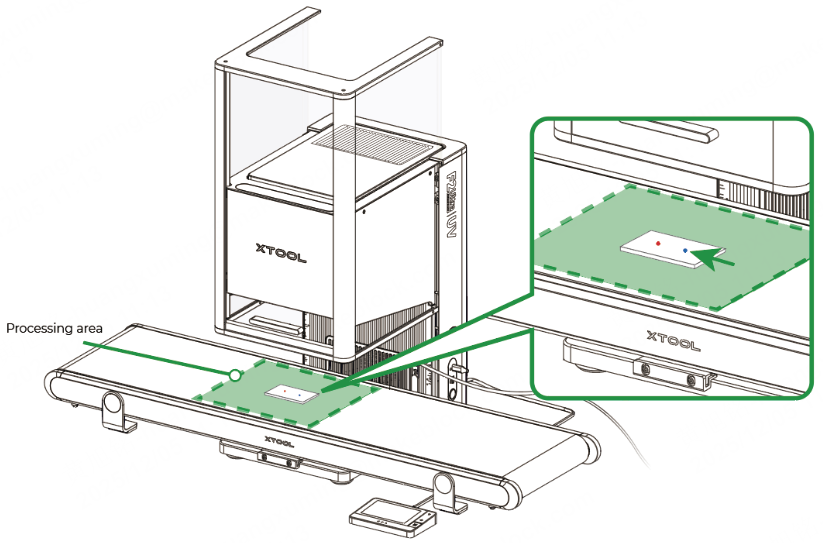

2. Place a material and select the material name

(1) Place a material in the processing area, ensuring that the blue light spot falls on the surface of the material.

Warning: Do not use thin materials permeable to light (such as paper and cloth). Laser beams may penetrate the material, then fall on the belt and damage it.

(2) On the right side of xTool Studio, click Unknown Material, select the name of your material, and click Apply.

Note:

- If you can't find your material in the list, you can leave it as Unknown Material and set parameters manually in later steps.

- If you select a material from the material list, the software will automatically set parameters for laser processing. The default settings apply to xTool materials. You can adjust the settings based on your needs.

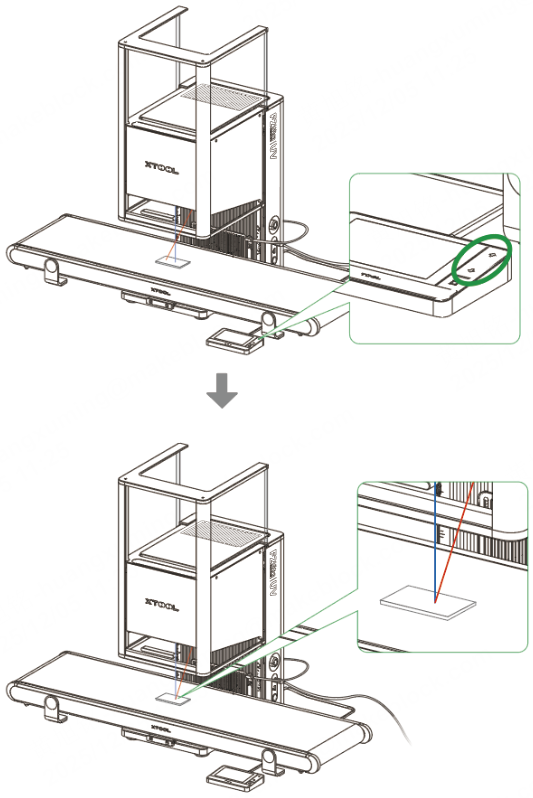

3. Perform laser focusing

Hold down on the Up/Down button for laser module to lift or lower the laser module. When the red and blue light spots overlap, the focus is successfully set.

Note: The blue light spot does not move. If the laser module moves up, the red light spot moves towards the left. If the laser module moves down, the red light spot moves towards the right. xTool F2 Ultra UV supports auto-focus and manual-focus. Here we use manual-focus. For more information on how to use auto-focus, see Perform Laser Focusing.

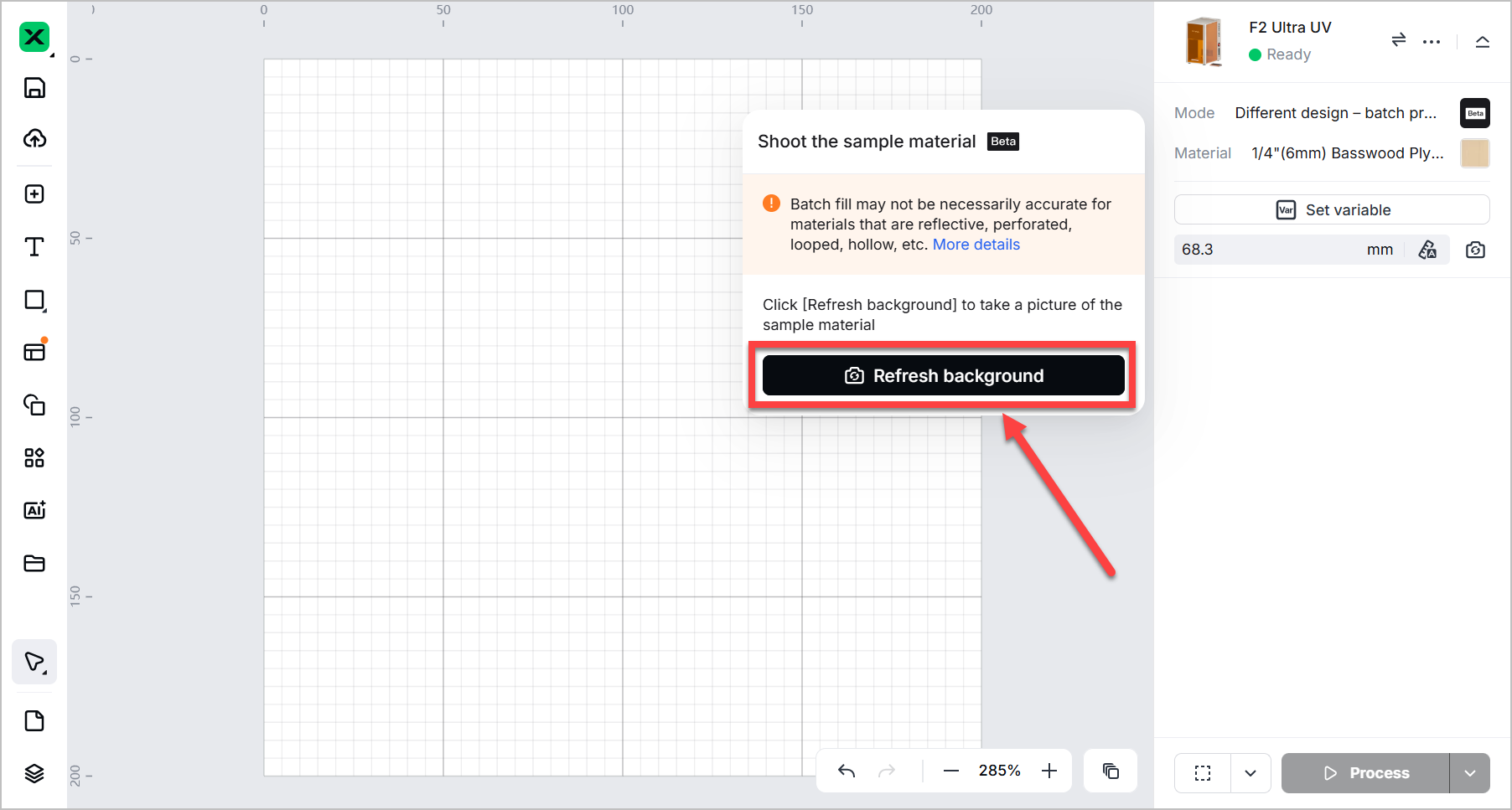

4. Shoot background and design processing objects

(1) In the pop-up window, click Refresh background.

xTool Studio takes a photo of xTool F2 Ultra UV’s processing area and inserts the photo as the canvas background. You can position processing objects based on the background.

Note:

- To ensure positioning accuracy, set the laser focus before shooting background.

- Ensure that the background photo can fully and clearly display the material. You can adjust the shooting environment by adjusting the device's fill light or pulling down the protective enclosure.

- If the materials in the photo have obvious shadows or are not clear, adjust the material position and click the Refresh background icon in the top-right corner of xTool Studio to take a new photo.

(2) Using the tools to the left of the canvas, create objects inside the material.

For more information on how to use xTool Studio to design objects, see Software Learning Center.

(3) If you need to set multiple objects as one variable, please unite or combine them into one. (A variable can only be set for one object.)

Example of compounding:

|

|

Example of uniting:

|

|

(4) On the right side of xTool Studio, click Set variable.

(5) Select the objects you want to set as variables, and click + Add variable. After setting all the variables, click Next.

Note: A variable can only be set for one object.

(6) Click + Add, and then a new row will be added, which indicates another design to be printed.

Note: The first row indicates the original design. You can also import data in batches. For detailed instructions, see Import data in batches.

(7) Change objects for each variable.

- For a vector, click Replace vector and choose a vector file from your local storage to upload.

Supported vector formats: SVG, DXF.

- For a bitmap image, click Replace image and choose an image from your local storage to upload.

Supported image formats: PNG, JPG, JPEG, BMP, WEBP.

- For text, double-click the text to edit it.

(8) After adding designs and setting variables, click Confirm.

5. Set processing parameters

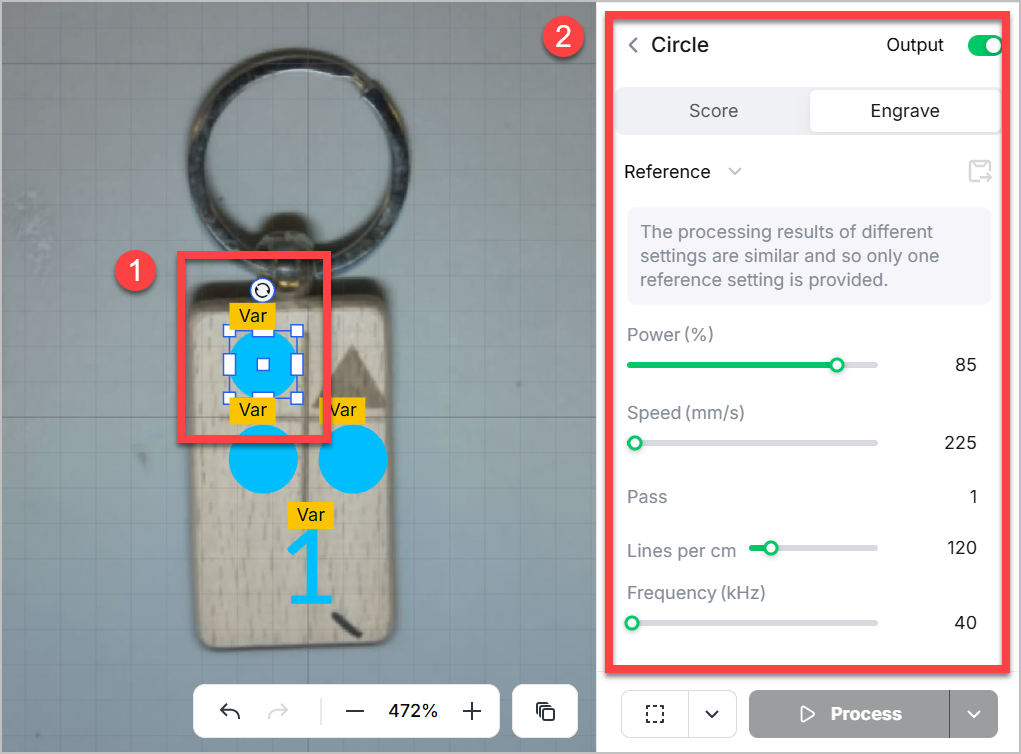

(1) Select objects on the canvas and set parameters for them on the right.

Note:

- The conveyor does not support laser cutting.

- For more information about the processing parameters, see Processing Parameters for xTool F2 Ultra UV (Test Matrix).

(2) Select all the objects on the canvas, and click Next in the Design a processing object window.

6. Frame out the sample material

The first material placed in the processing area is used as the sample material. During batch processing, xTool Studio will fill the other materials based on the sample. Framing out the sample material helps improve batch filling accuracy.

(1) In the pop-up window, move or resize the bounding box to include the sample material inside it.

(2) Place other identical materials in or to the right of the processing area. Ensure that they do not touch or overlap with each other.

(3) Turn on or off Same-direction Processing as needed. Then, click Process.

If Same-direction Processing is enabled, all the designs will be engraved in the same direction no matter how the materials are placed. To maintain consistency, you are advised to turn it off.

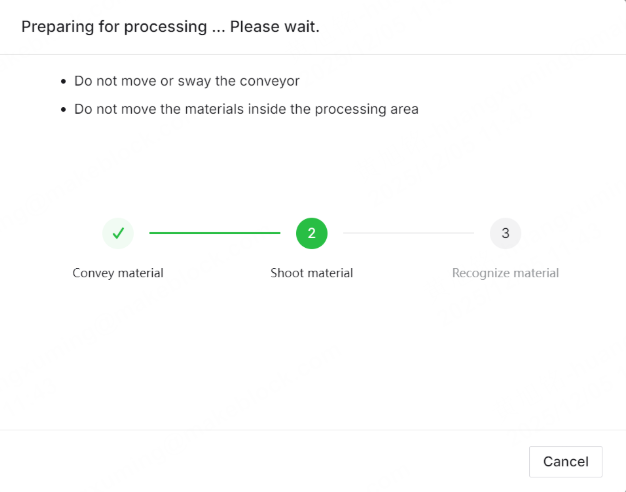

(4) Wait for xTool Studio to fill the designs on the materials.

7. Start processing

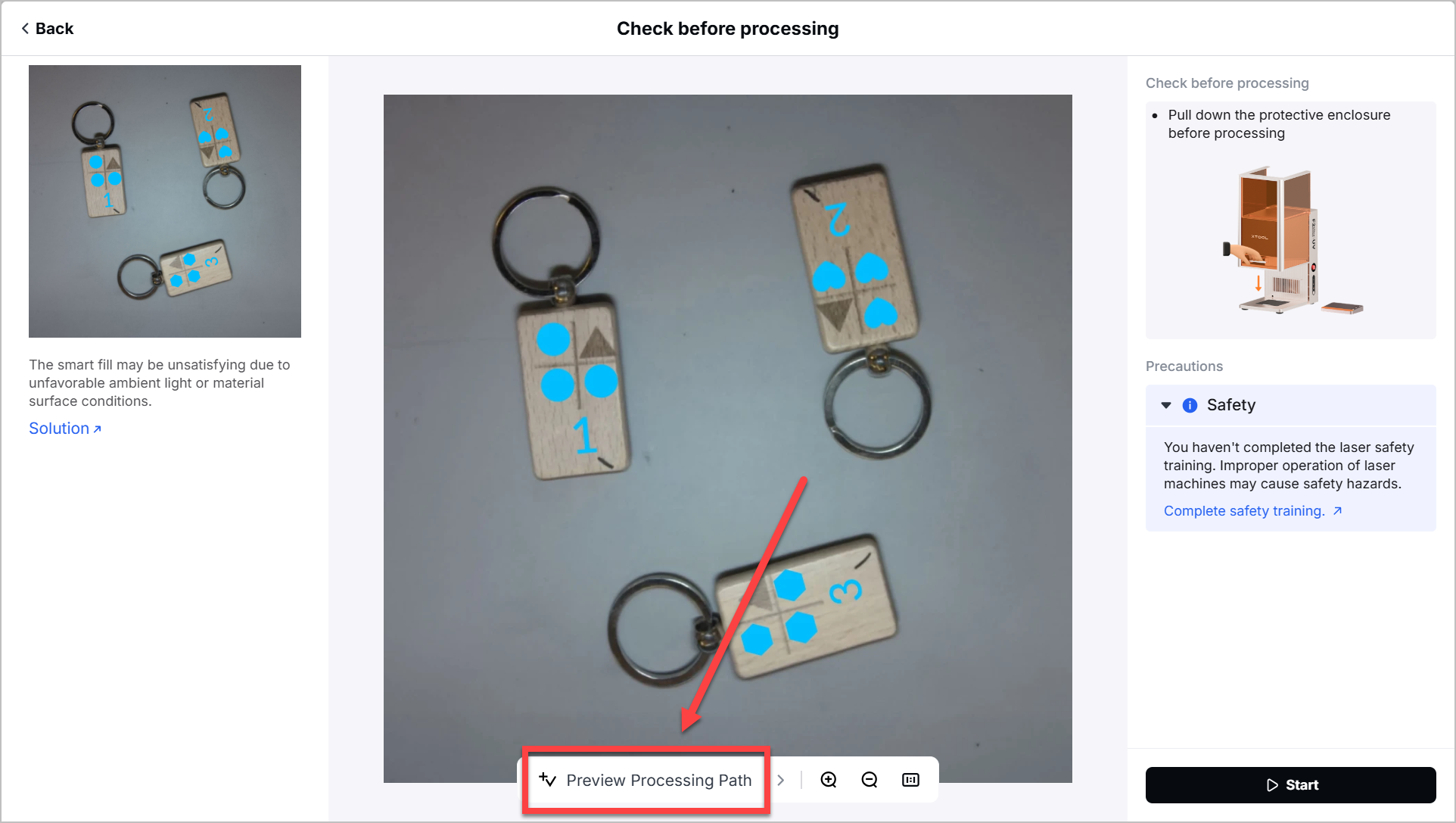

(1) In the bottom, click Preview Processing Path to check the processing path.

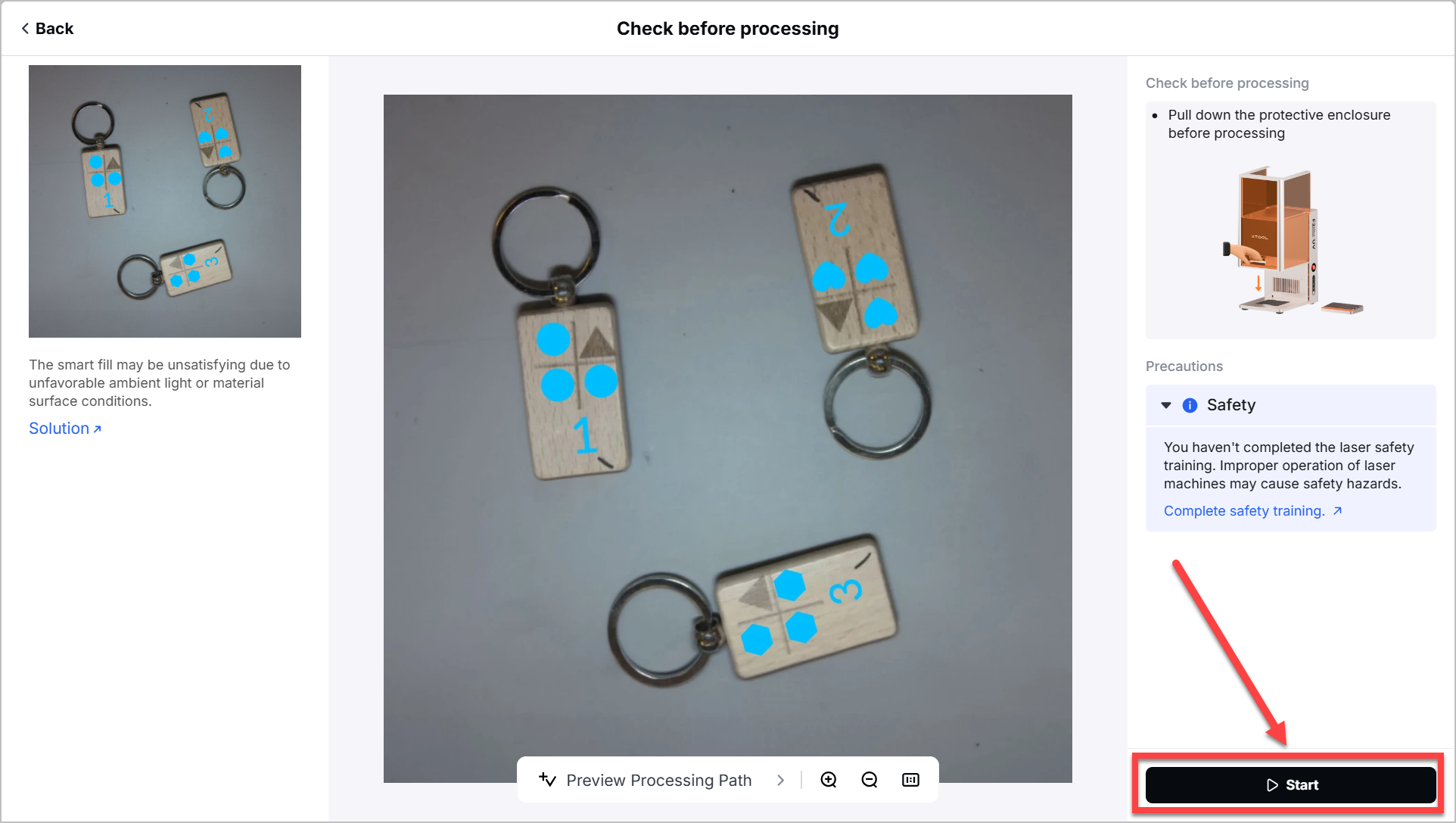

(2) Pull down the protective enclosure until it remains no more than 5 mm above the materials. And wear a pair of goggles that can shield laser beams of 355 ± 5 nm wavelengths.

Note: If you purchase goggles from our website, ensure that you select this specific pair.

Note:

When xTool F2 Ultra UV is used with a conveyor, its protective enclosure cannot be fully closed. For your safety, it is recommended that you wear goggles during processing.

Safety goggles are not included with xTool F2 Ultra UV or the conveyor. Please purchase them separately.

(3) In the bottom-right corner of the software, click Start.

(4) Press the XTOOL Start/Stop button on the touchscreen controller to start processing.

(5) During processing, keep adding new materials to the conveyor. Place them to the right of the processing area.

Note:

- When placing materials, keep your hand away from the processing area to avoid injuries.

- Do not place a material close to the edges. Otherwise, the material may fail to be processed.

- Ensure that the materials do not touch or overlap with each other.

8. Stop processing

- Auto-stop: If no material is detected for 5 consecutive times, batch processing will automatically end.

- Manual-stop: Click Cancel in xTool Studio or double press the XTOOL Start/Stop button on the touchscreen controller.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.