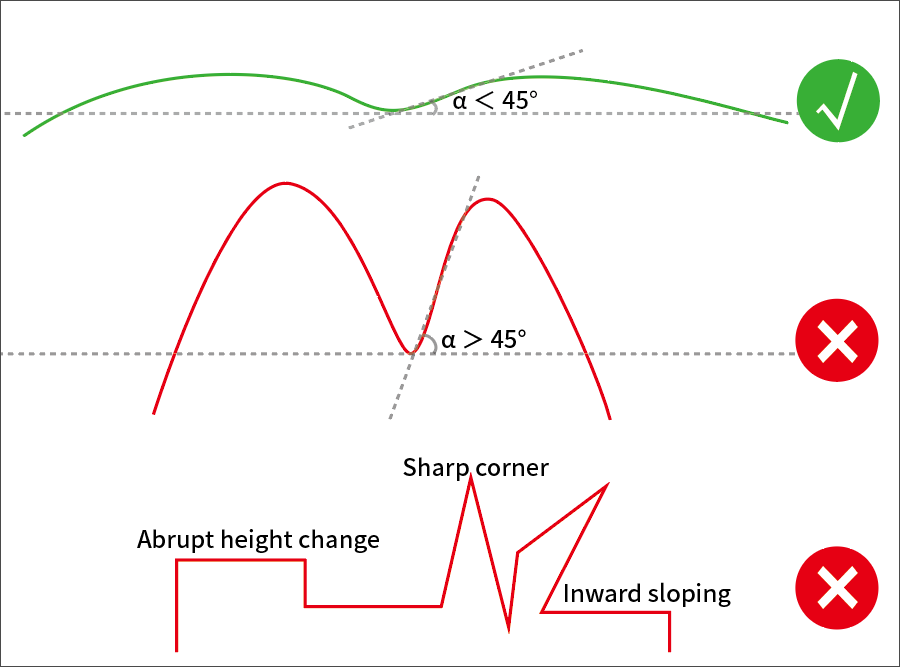

Requirements for materials

Only smooth surfaces with an angle lower than 45 degrees are supported.

1. Connect xTool P3 to the software

Go to Operate xTool P3 with xTool Software and follow the steps. Make sure the device is connected successfully.

2. Place the material

Open the lid of xTool P3, and place the material to be processed on the slats.

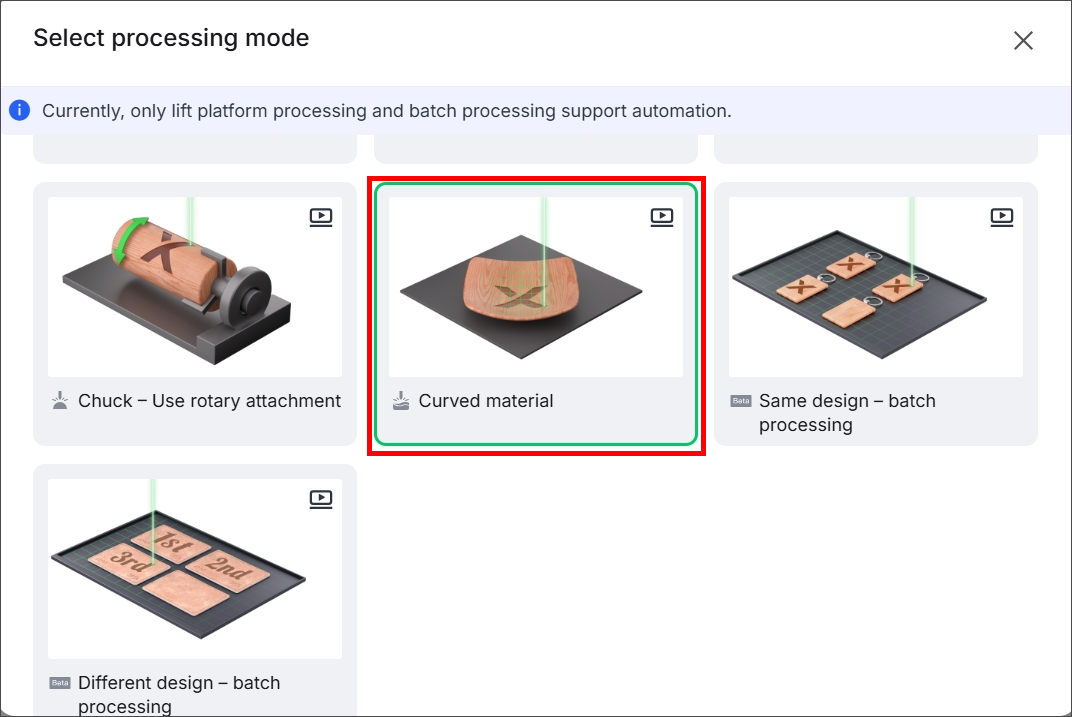

3. Select the processing mode and material

(1) On the right panel, select Curved material as the processing mode.

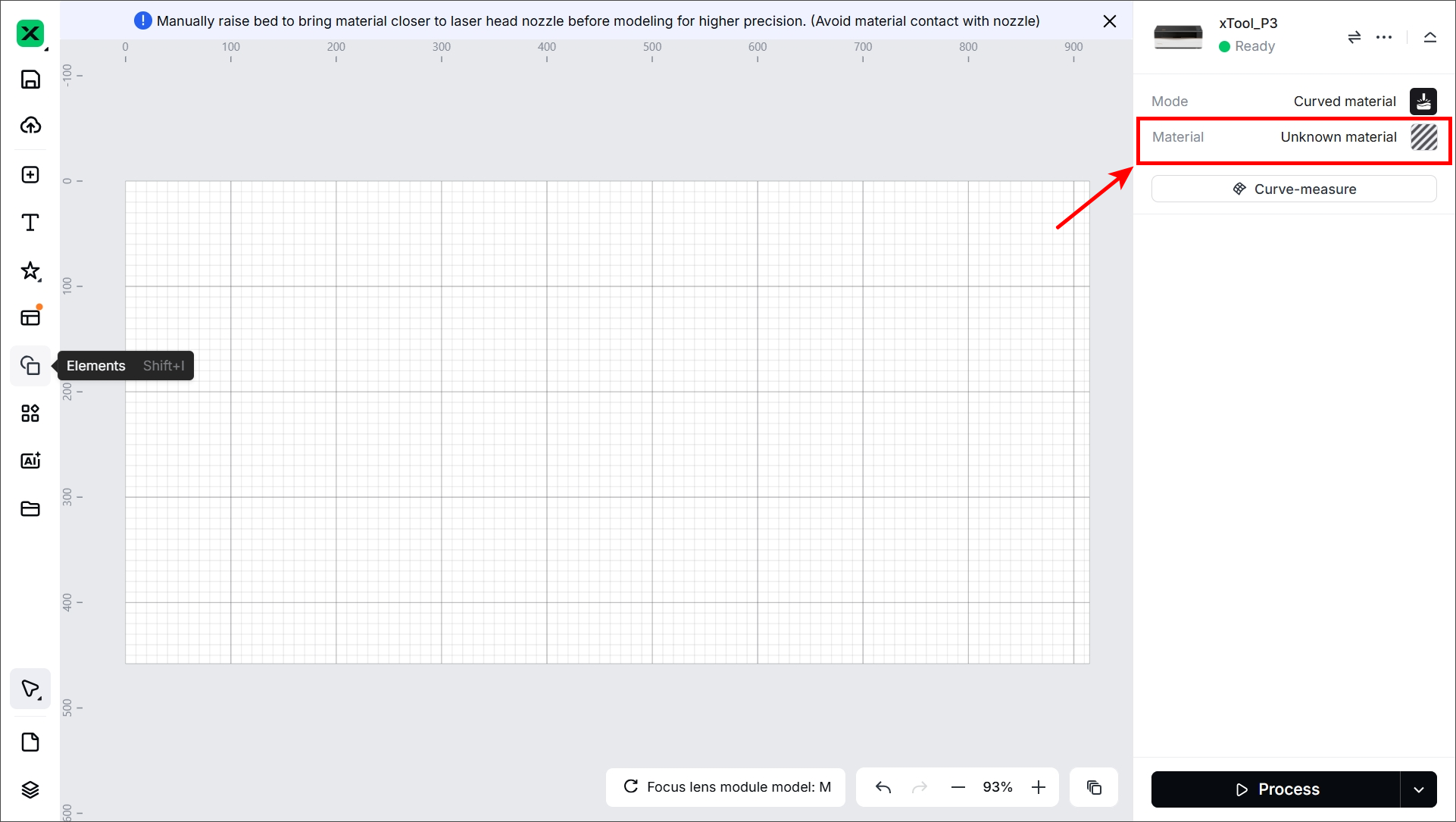

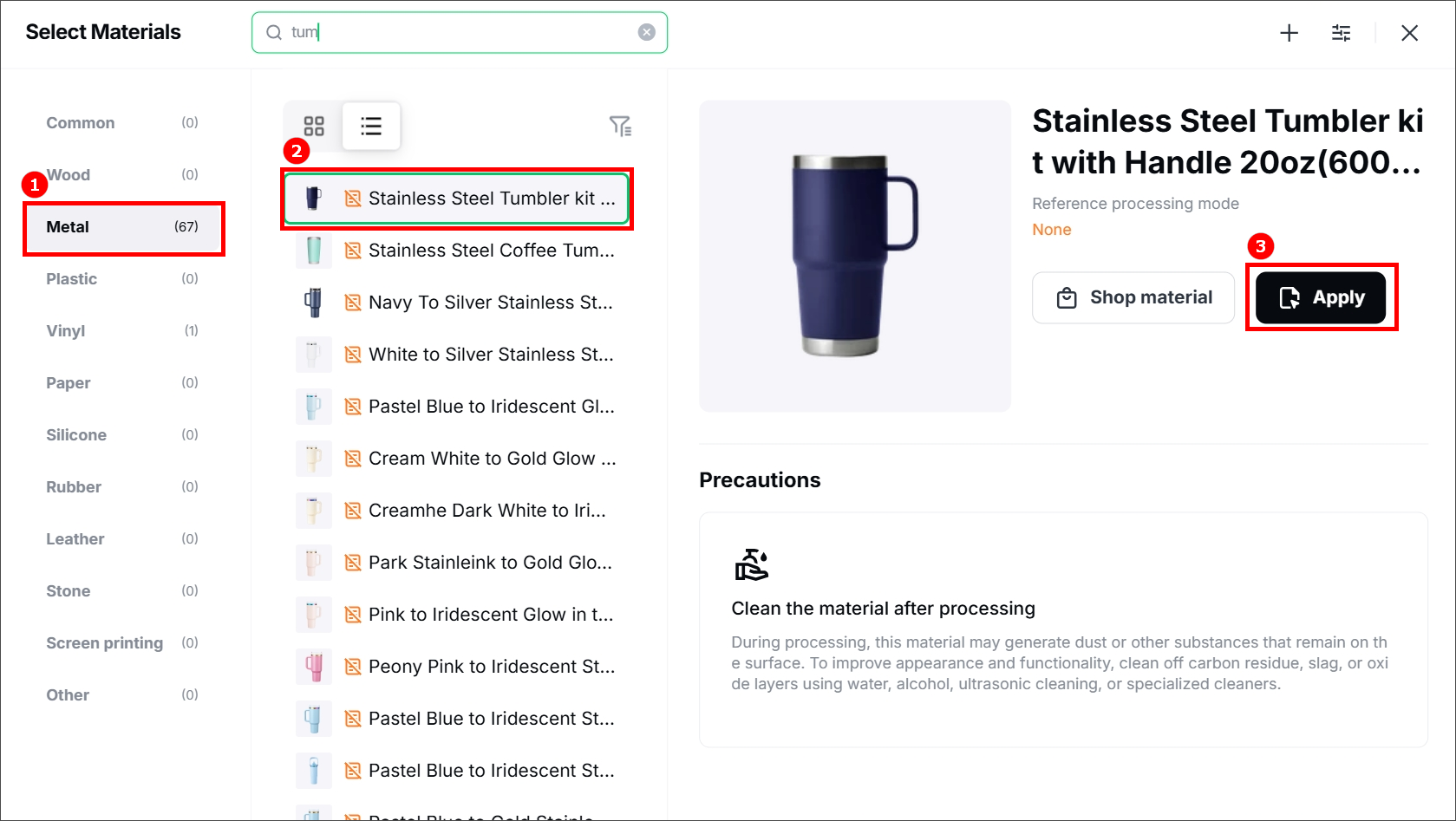

(2) Under Mode, select the material and click Apply.

After you select a material on the material list, the software will automatically set parameters for laser processing. The default settings apply to xTool materials. You can adjust the settings based on what you need. If you select user-defined material, you need to set the processing parameters by yourself.

4. Adjust the distance manually

(1) Close the lid.

(2) Turn the knob to adjust the height of the lifting platform. Ensure that the laser module nozzle is positioned close to the material without making contact.

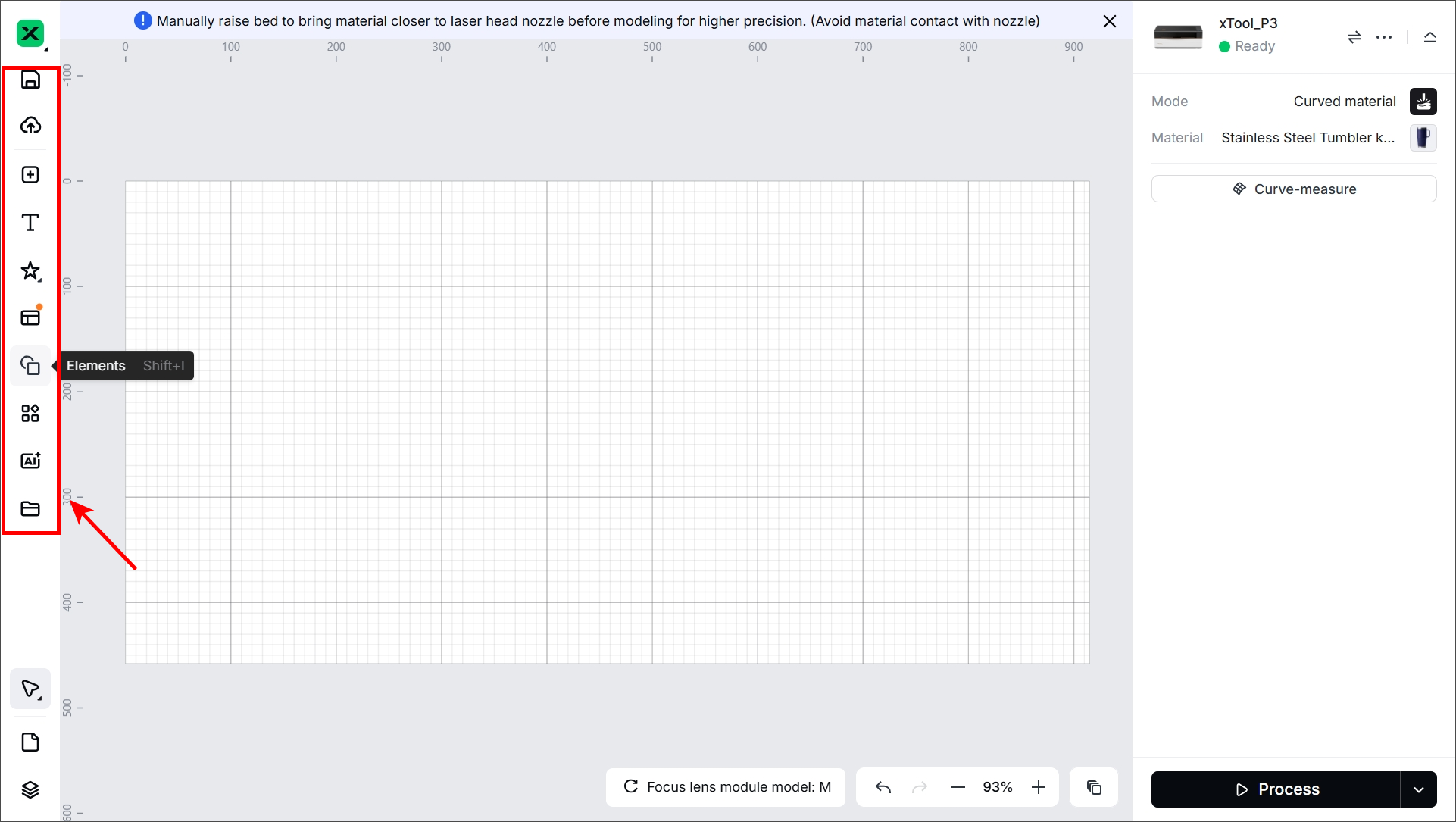

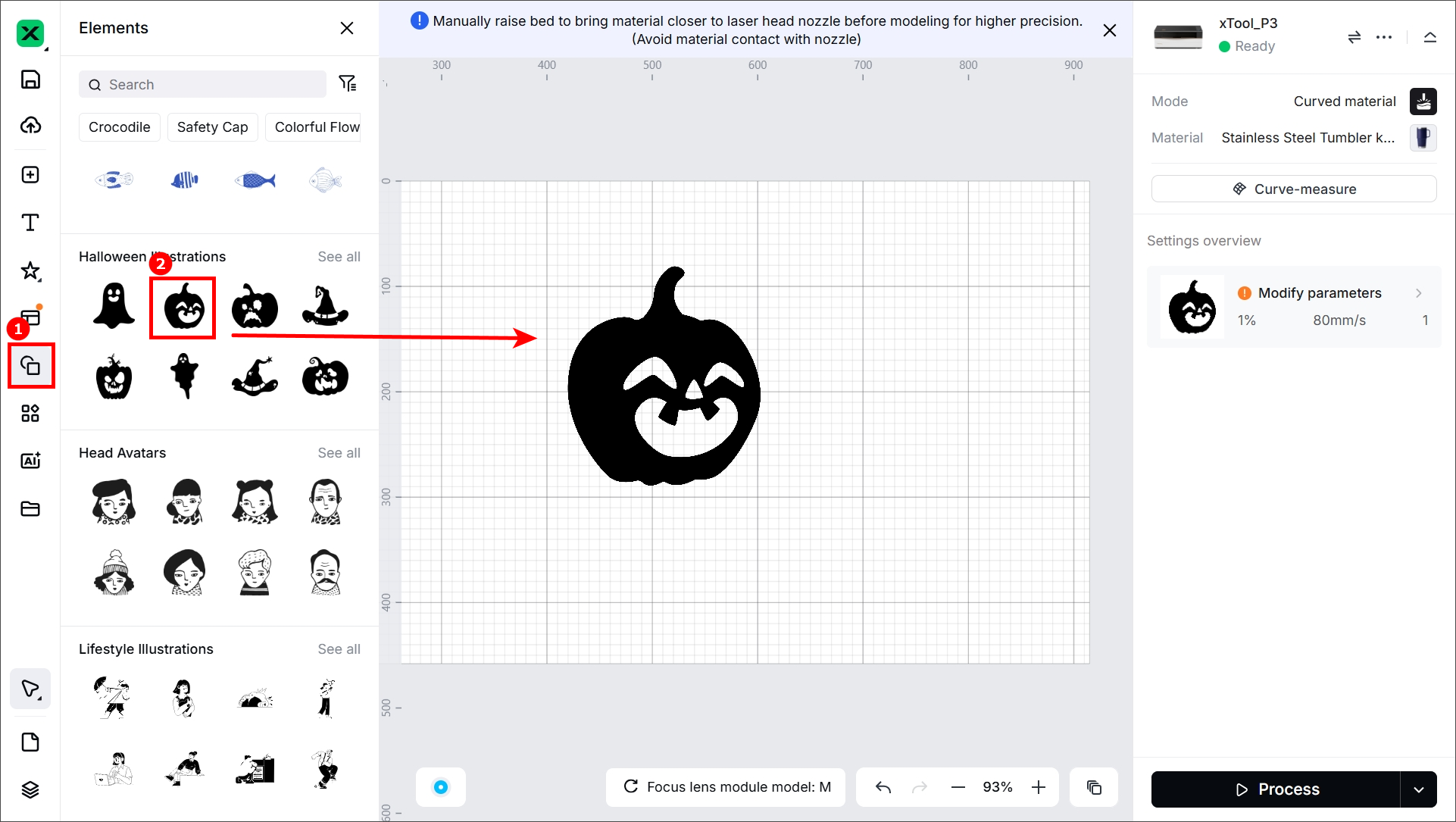

5. Design a processing object

Use the left-side tools to create objects on the canvas.

💡 Note: You can import images, insert shapes, enter text, draw vector graphics, and so on. For more information on how to use the software to design objects, see Software Learning Center.

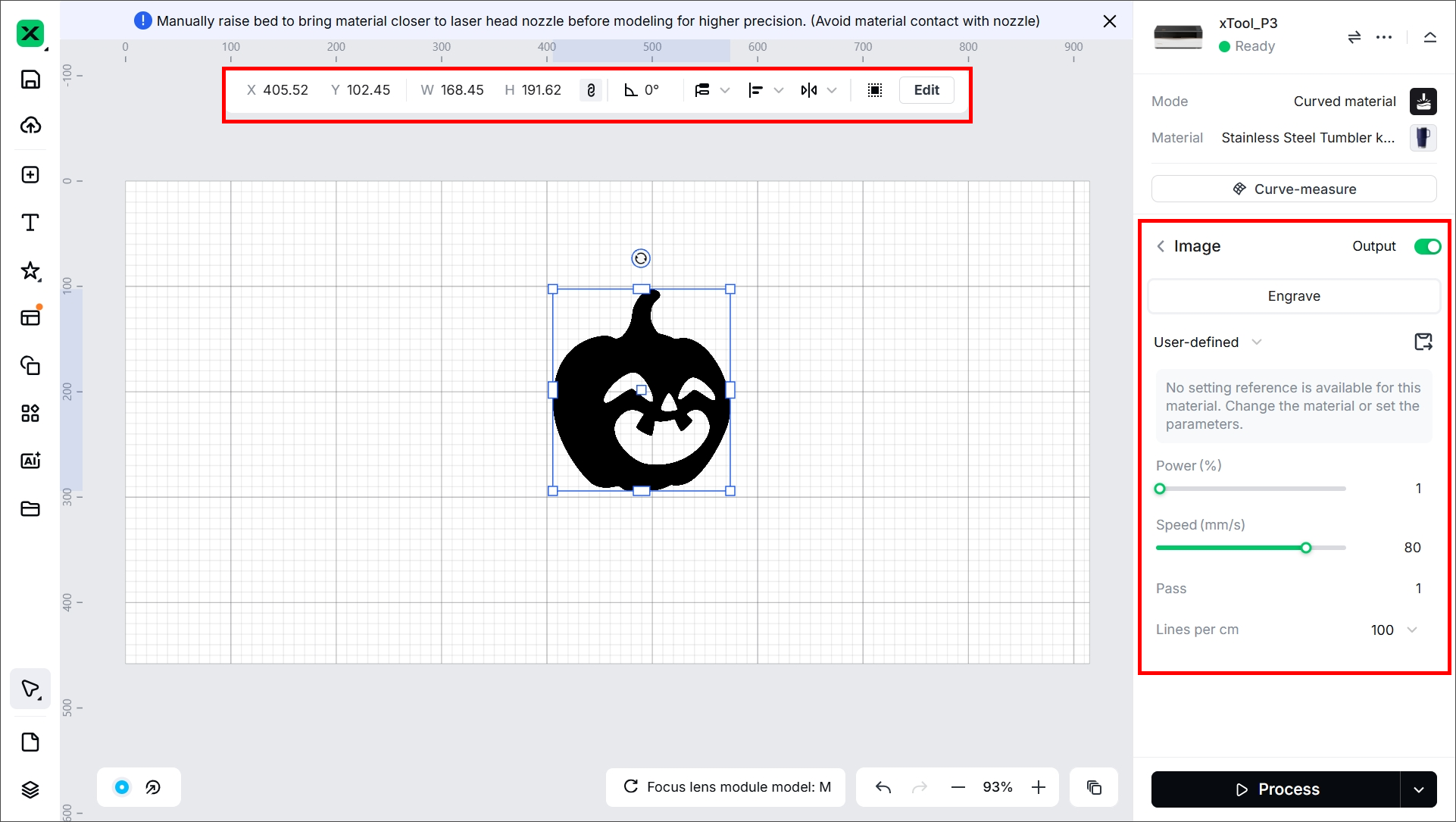

6. Edit objects and set parameters

(1) Select objects on the canvas.

(2) Set parameters for them in the right panel. You can further edit the objects by using the other features in the upper panel.

💡 Note: You need to set parameters for every object. A missed object may fail to be processed.

The parameters that can be set for bitmap objects and vector objects are different. You can select multiple objects of the same type and set parameters for them at once.

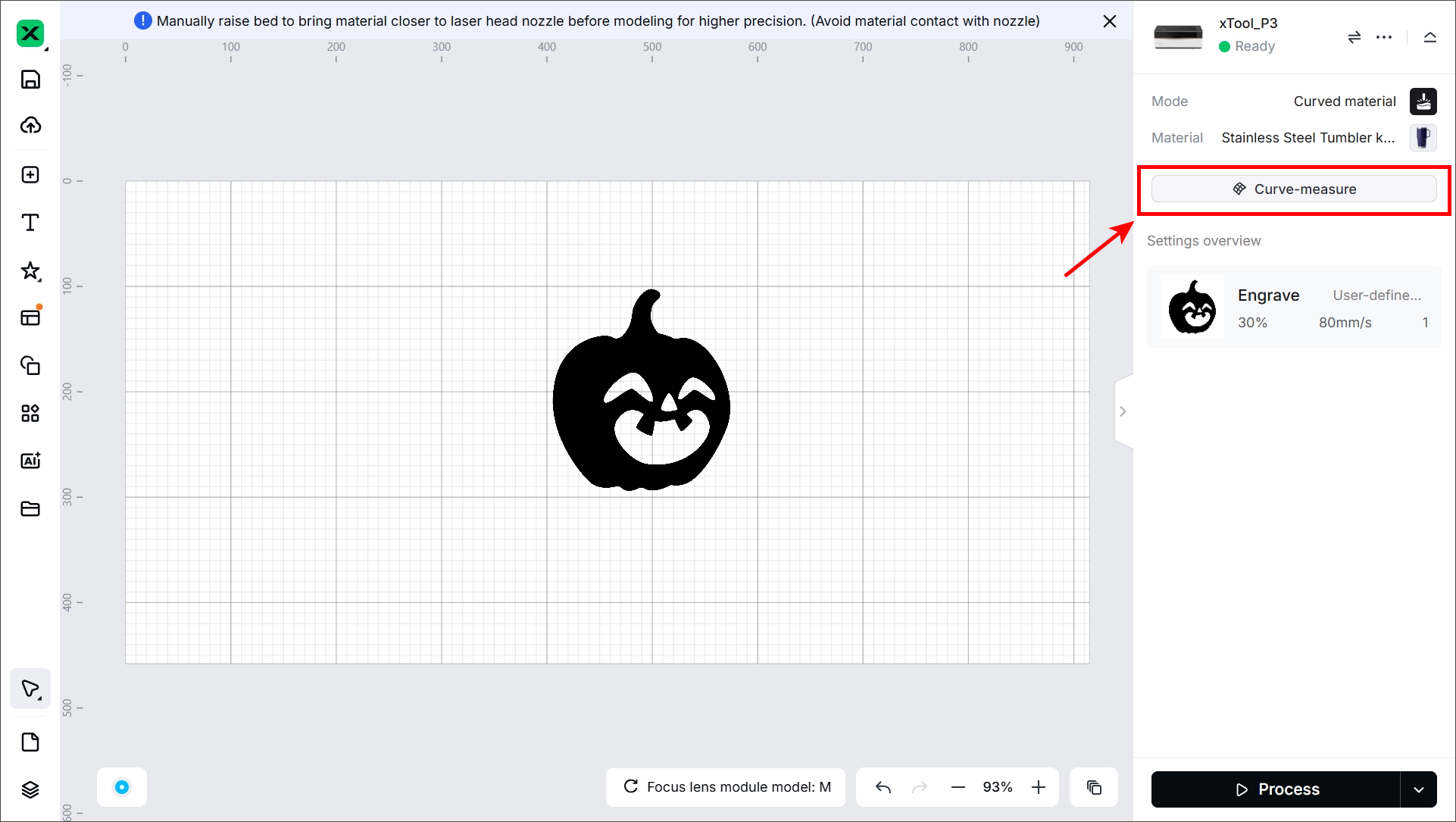

7. Measure the curved area

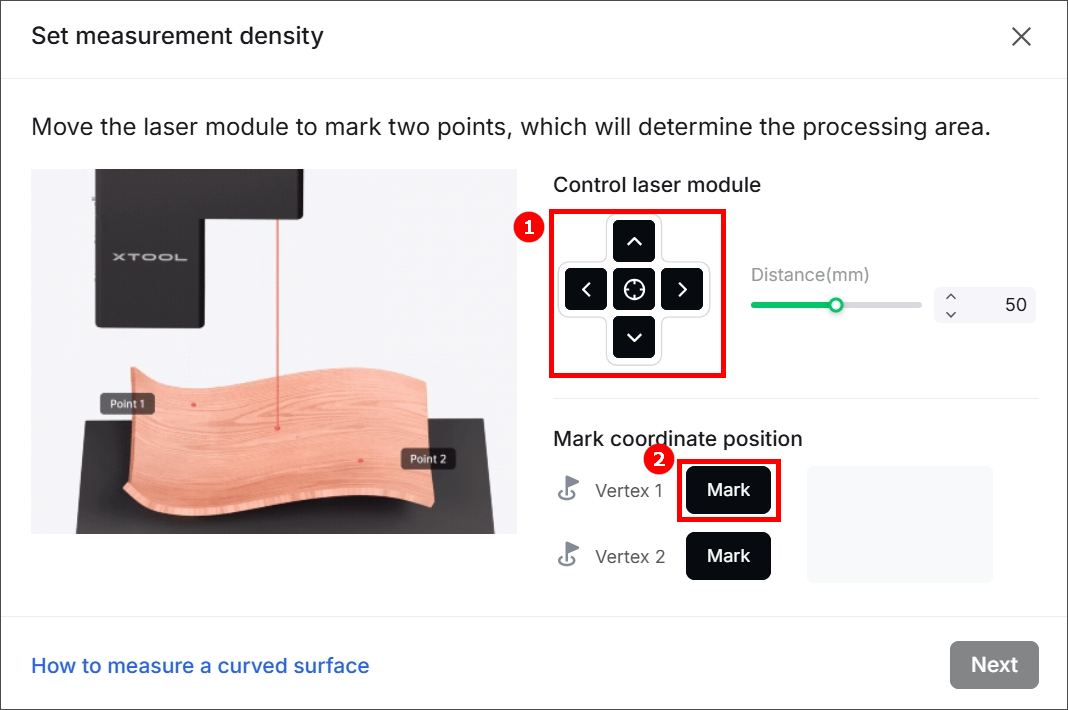

(1) Click Curve-measure to measure the curved area.

(2) Set the area to be measured.

- Move the laser module by clicking the arrow keys to make the red spot fall at the upper left vertex of the area to be measured, and click Mark to mark vertex 1.

💡Tips: You can set the distance the laser module moves each time when you click an arrow key.

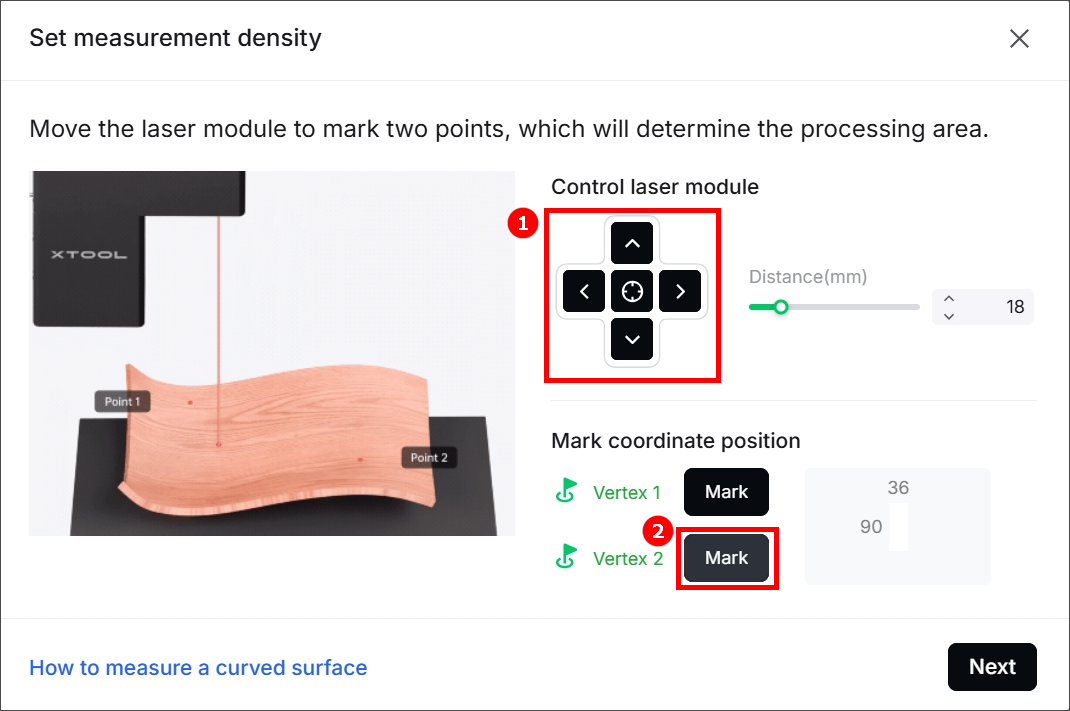

- Move the laser module to make the red spot fall at the lower right vertex, and click Mark to mark the vertex 2. The software will measure the area you selected.

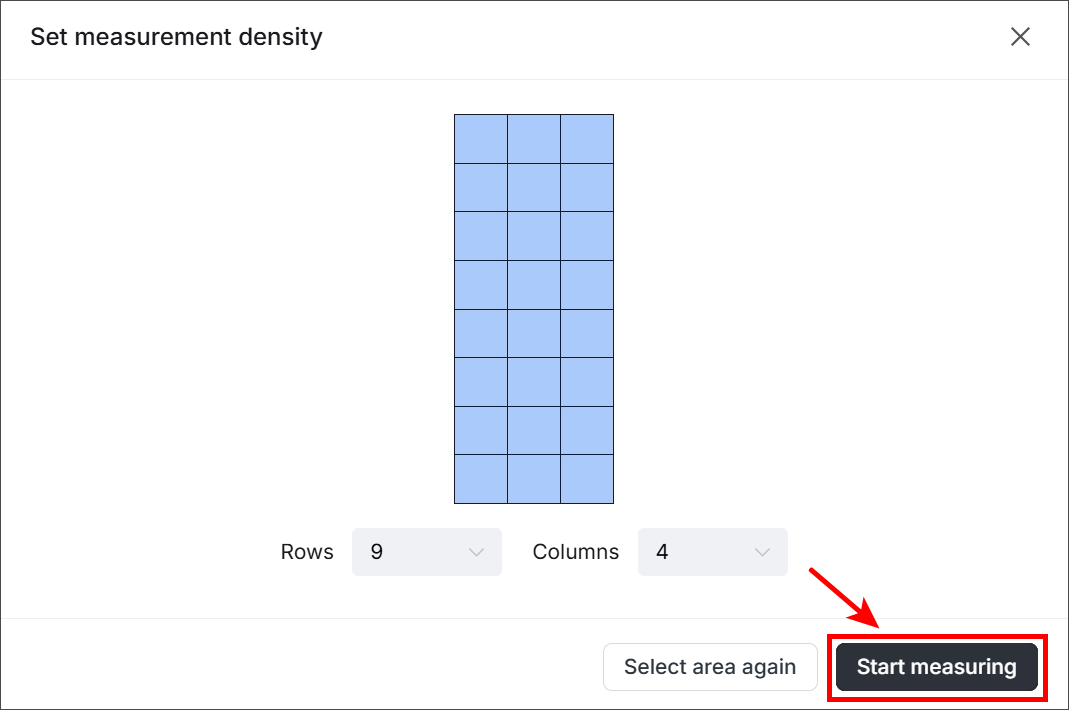

(3) Set the measurement density.

A recommended density is provided based on the area size, which can be adjusted as needed. Increasing the density enhances model precision but also extends the measurement time.

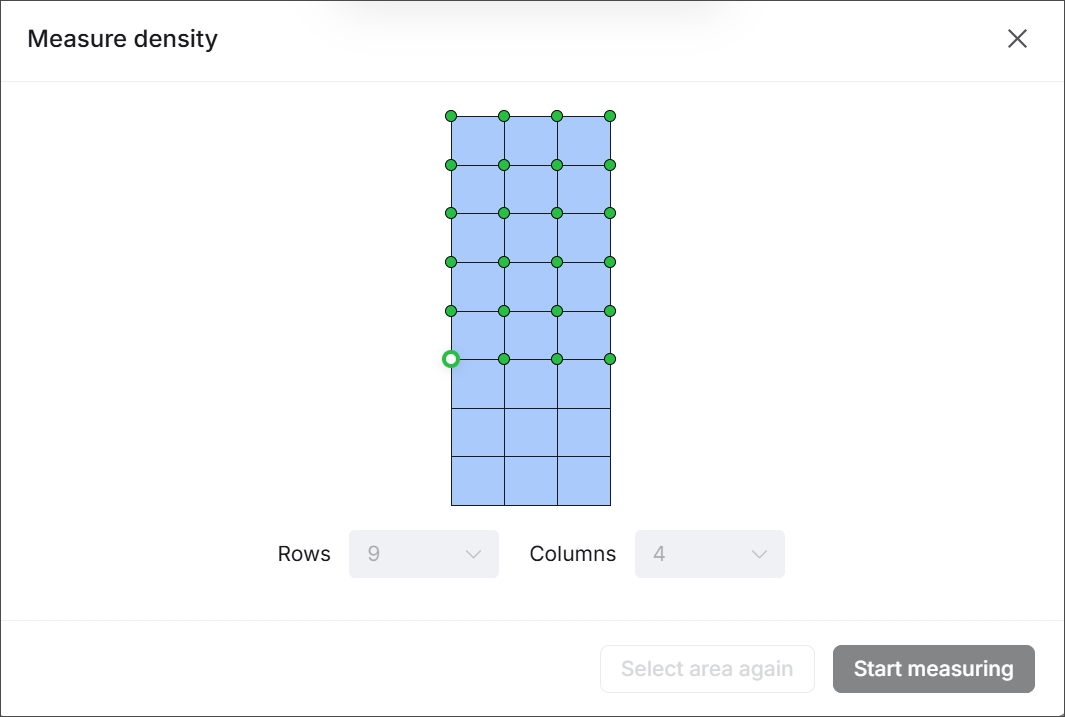

Click Start measuring. The software starts to measure the area, and you can see the progress.

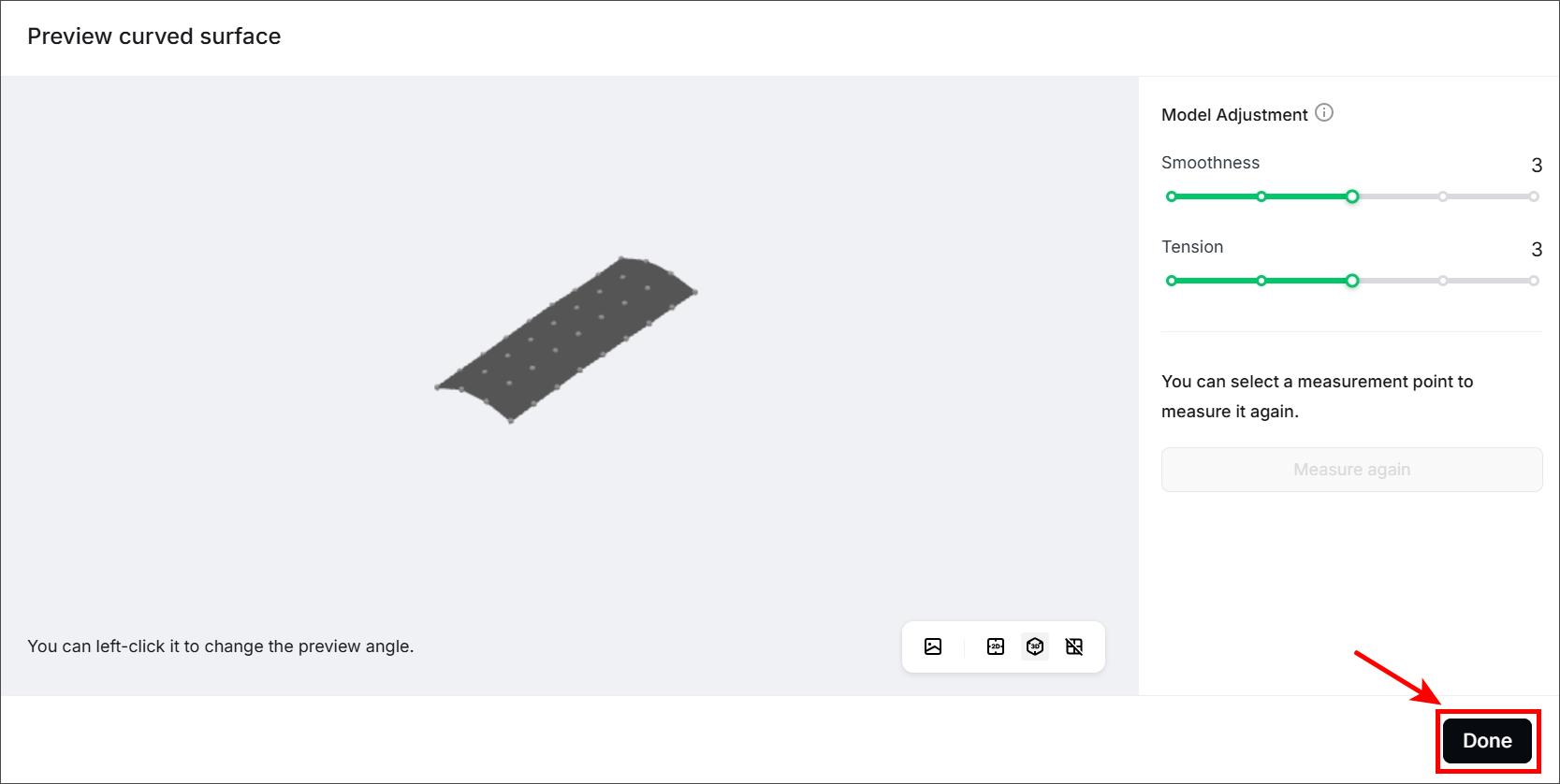

(4) After the measurement is complete, the software generates a model. You can hold down the left mouse key to change the viewing angle, and adjust it by setting the smoothness and tension.

Click Done to save the model.

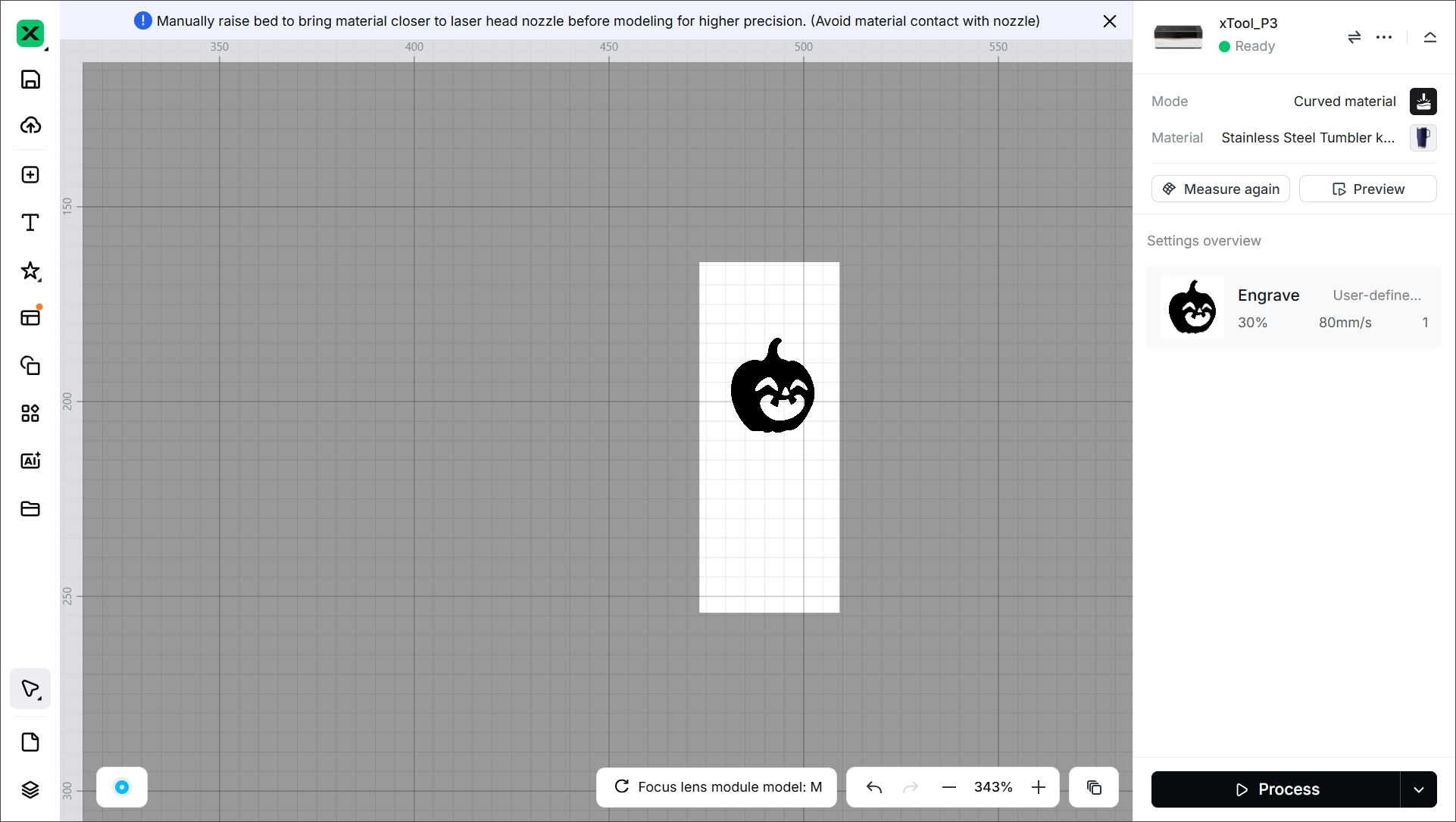

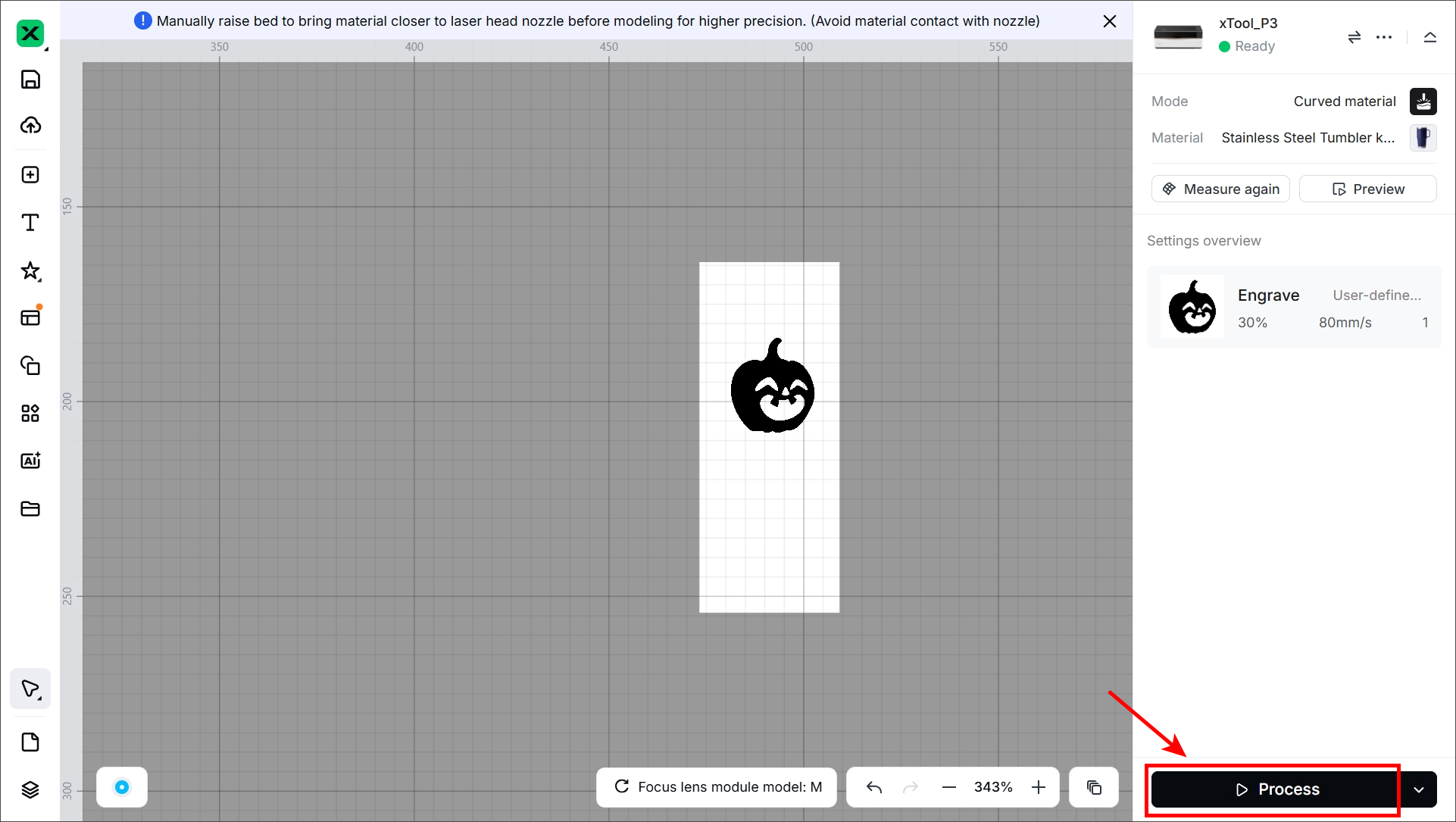

You can see the object in the curved area.

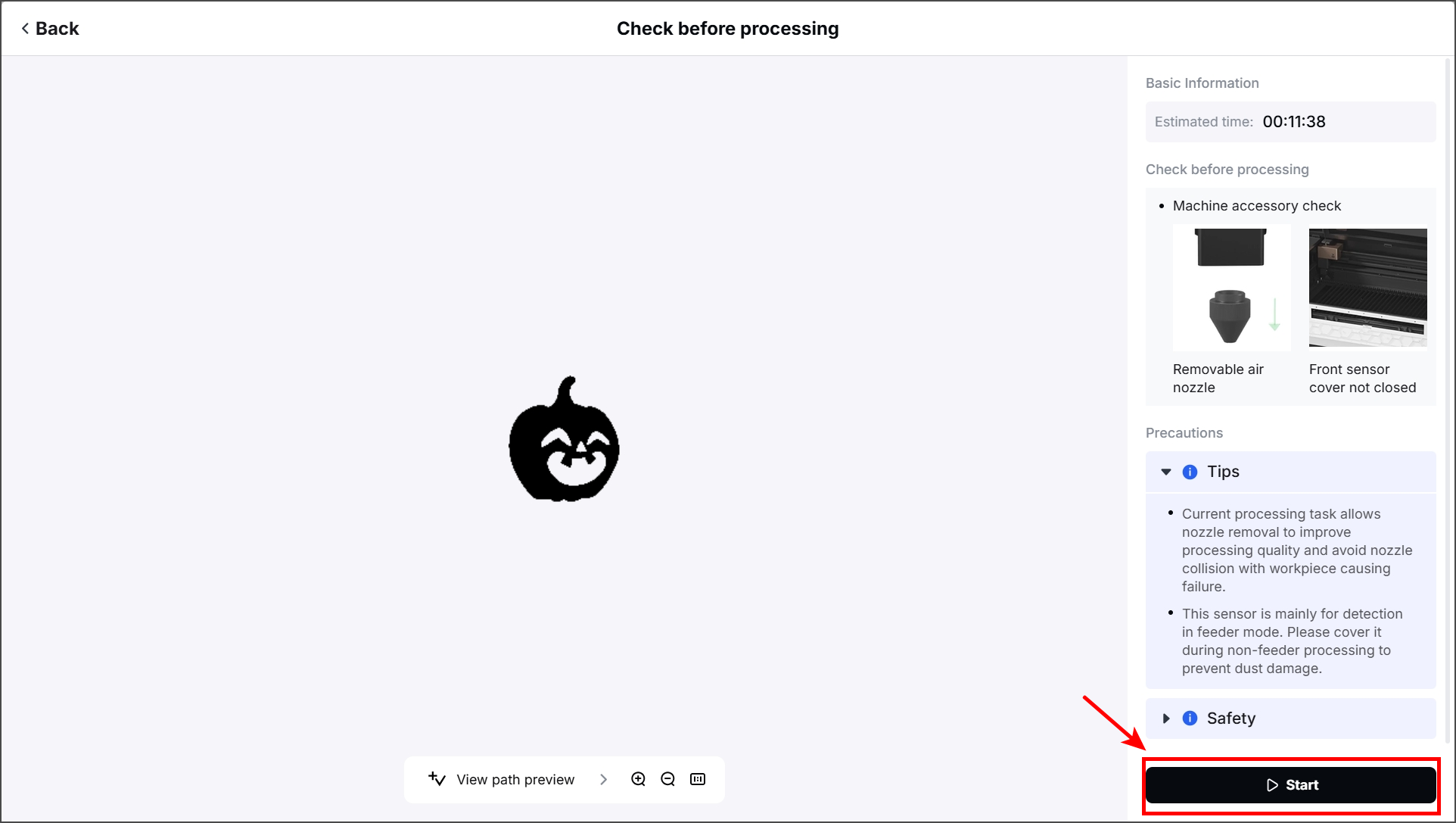

8. Start processing

(1) In the bottom right corner of the software, click Process.

(2) Check whether the accessories are prepared before processing on the right list.

(3) In the bottom right corner, click Start to start processing.

(4) When everything is ready, press the knob on xTool P3 to start processing.

(5) After the processing is complete, click Finished.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.