Prepare for installation

Power supply

xTool MetalFab Laser Welder 800W requires a 220 V – 240 V AC power supply, and works at a full load power of 3 kW. An individual branch circuit with a current-carrying capacity of 20 A or above is recommended.

Requirements on electrical facilities vary with power cables. Please consult a qualified electrician before installing the device to ensure that the device is installed in accordance with local electrical codes.

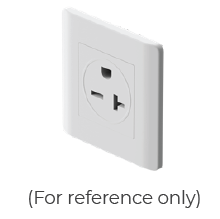

US standard

| Use a NEMA 6-20R power outlet

|

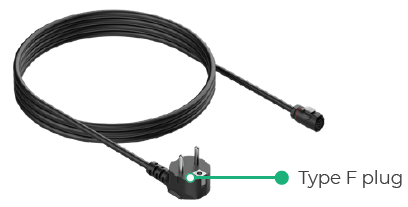

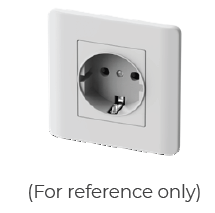

EU standard

| Use a Type F power outlet

|

Note: For the electrical requirements of other types of power cables, see Power Requirements for MetalFab Products in Different Countries and Regions.

Caution:

■ Ensure that the welder is powered separately. Do not use it with other high power equipment on the same circuit.

■ To ensure safety, it is recommended that you install a 20 A air circuit breaker between the power supply and xTool MetalFab Laser Welder 800W.

Workroom

Ensure that the workroom is well ventilated.

Shielding gas

xTool MetalFab Laser Welder 800W requires the use of shielding gas. Supported gas types include nitrogen and argon, and the gas purity must be over 99.99%.

Different processing types have different requirements for gas supply:

Processing type | Gas flow/pressure requirements | Necessary accessories |

Laser welding | Flow rate: 15 L/min – 30 L/min | Gas flow meter |

Laser cleaning | Gas pressure: 100 kPa – 200 kPa | Gas pressure regulator + gas flow meter |

Laser cutting | Gas pressure: 600 kPa – 800 kPa | Gas pressure regulator |

Note: xTool MetalFab Laser Welder 800W does not come with gas cylinders, gas generators, or related accessories. Please prepare them separately. |

Install xTool MetalFab Laser Welder 800W

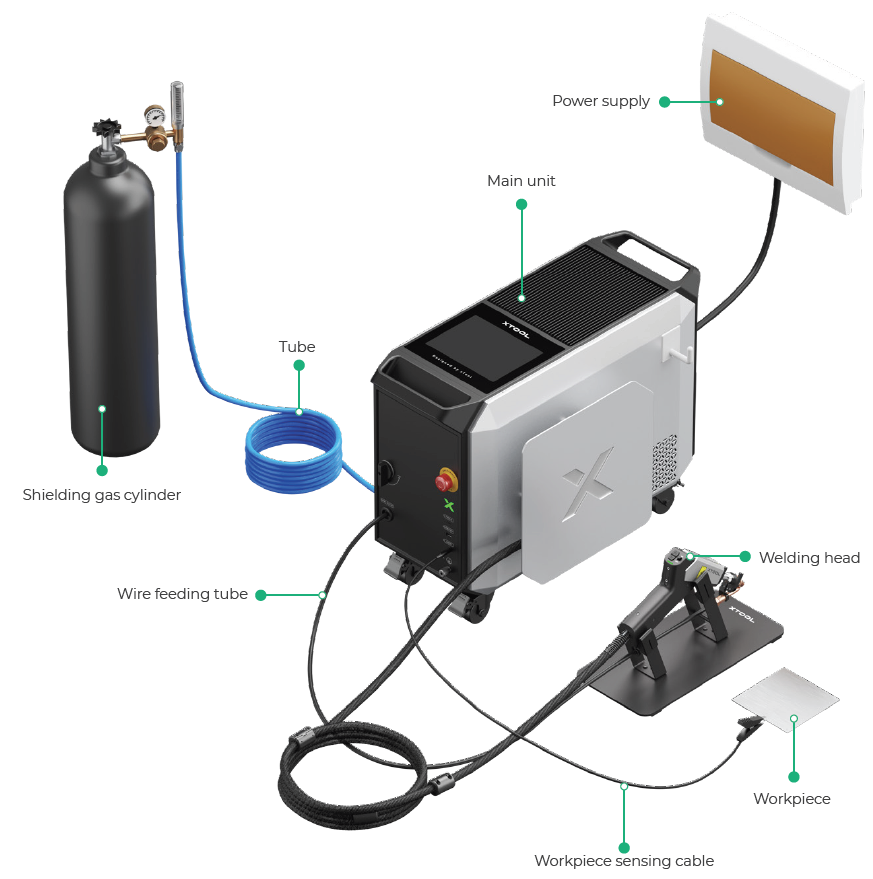

Cabling diagram

The following picture shows the cabling diagram of xTool MetalFab Laser Welder 800W. Please follow the detailed step-by-step instructions to complete the installation.

1. Place the main unit

Pull up the pedals on all four caster wheels, then move the main unit to the desired position, ensuring at least 10 cm of clearance at the front and back (to ensure good ventilation and heat dissipation).

Then, step on the pedals to lock the casters and secure the main unit.

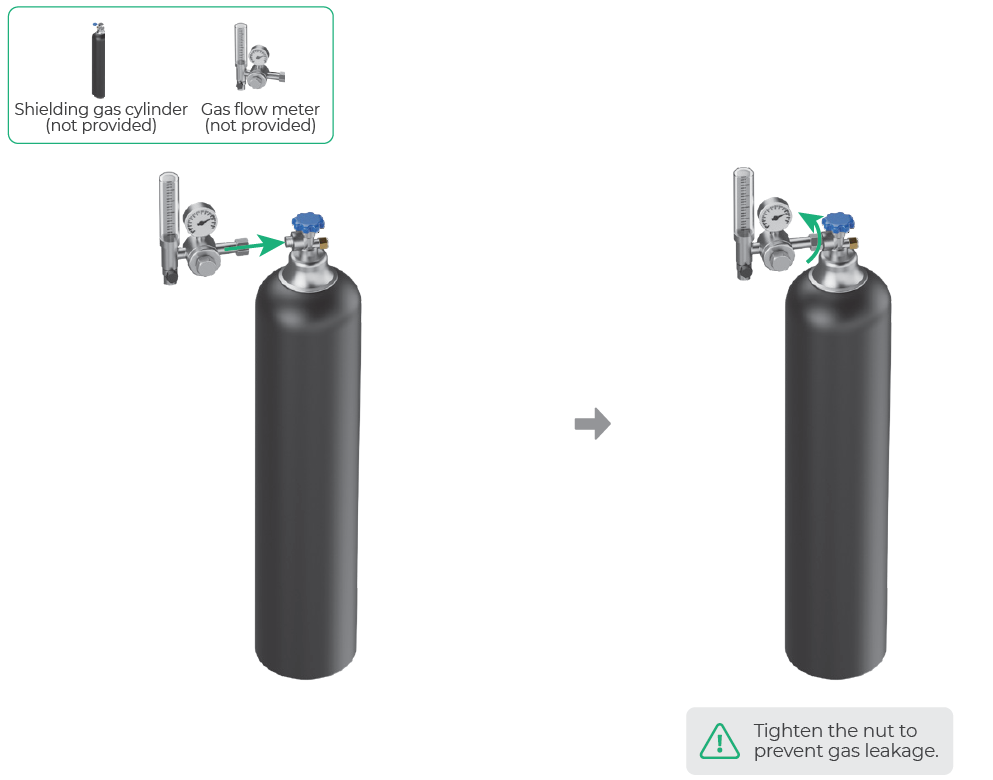

2. Connect the shielding gas cylinder

(1) Install a gas regulator on the shielding gas cylinder (or gas generator).

Note: ■ Laser welding requires a gas flow meter, laser cleaning a pressure regulator and gas flow meter, and laser cutting a pressure regulator. ■ Installing a gas flow meter on a cylinder is used as an example here. |

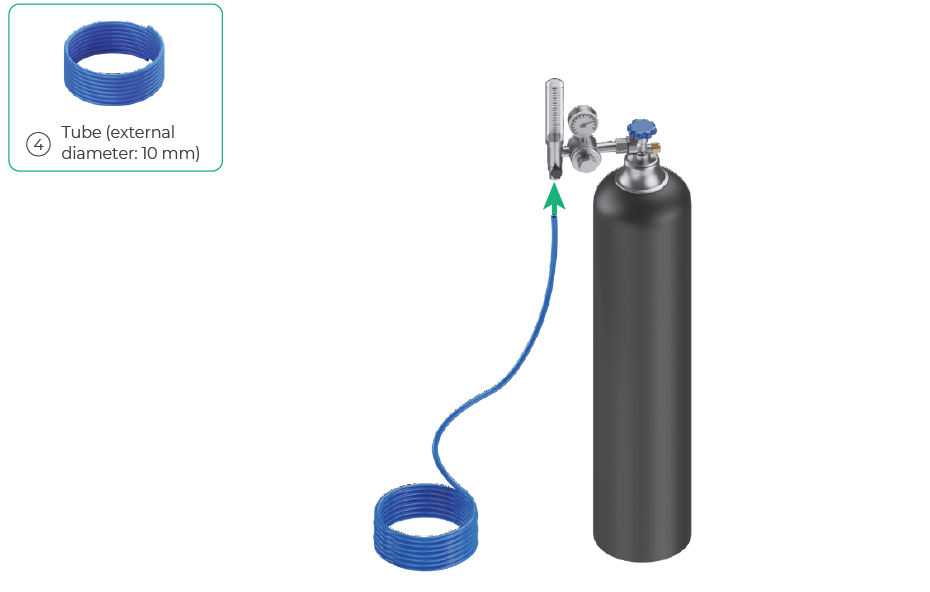

(2) Connect one end of the tube to the cylinder (or gas generator).

Caution: Do not open the gas cylinder valve yet. Open it only before laser processing. |

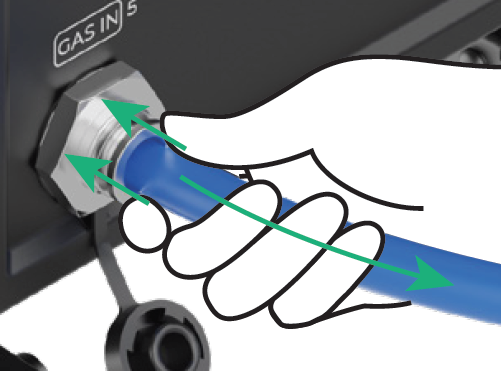

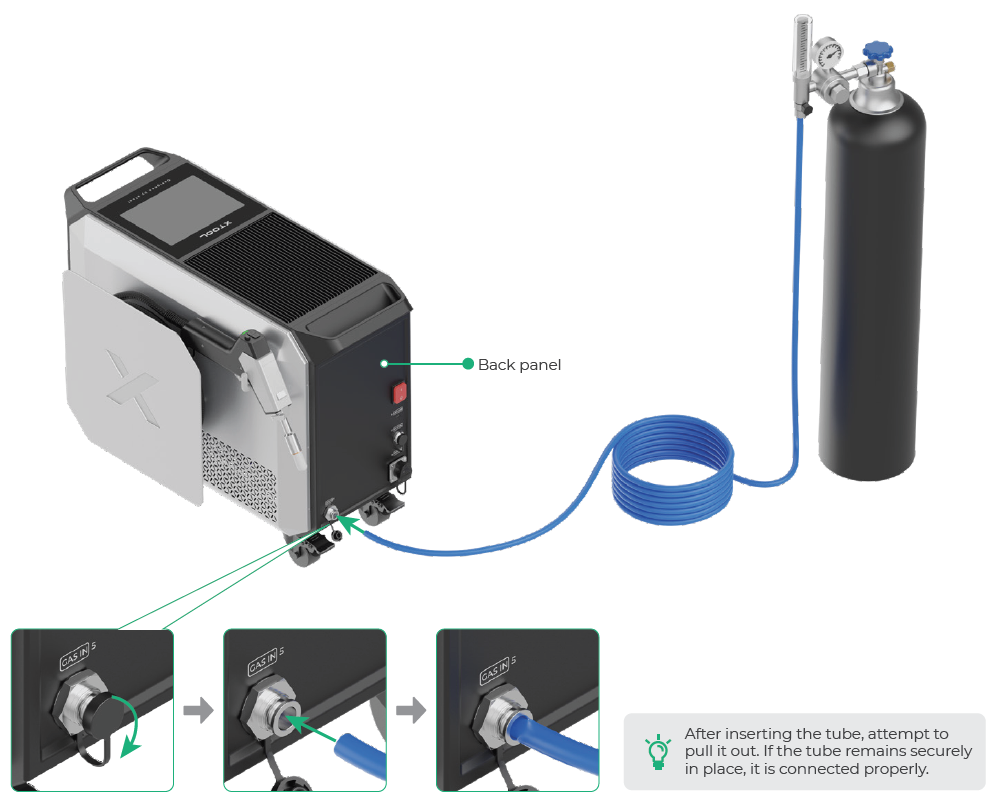

(3) Insert the other end of the tube into the shielding gas inlet on the main unit.

Tips: To remove the tube, push and hold the collet of the shielding gas inlet and pull out the tube.

|

3. Place the welding head

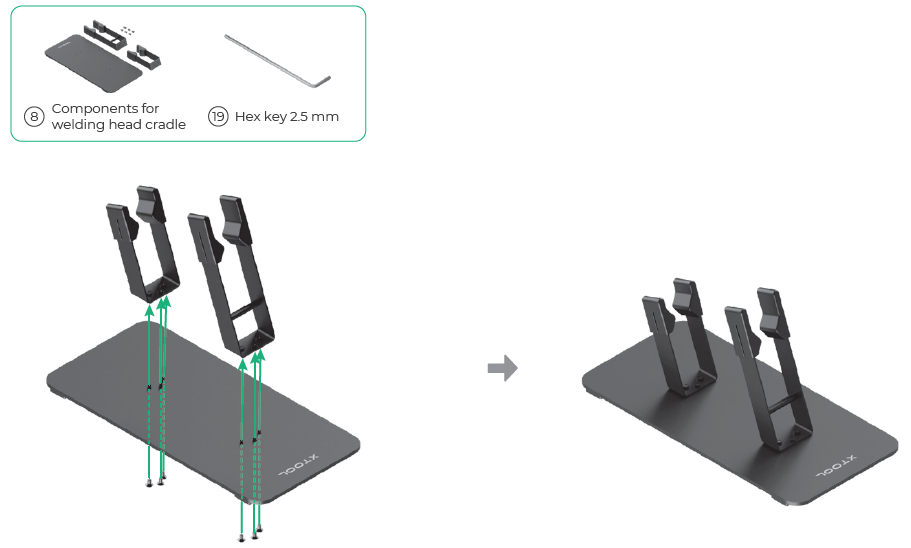

(1) Assemble the welding head cradle.

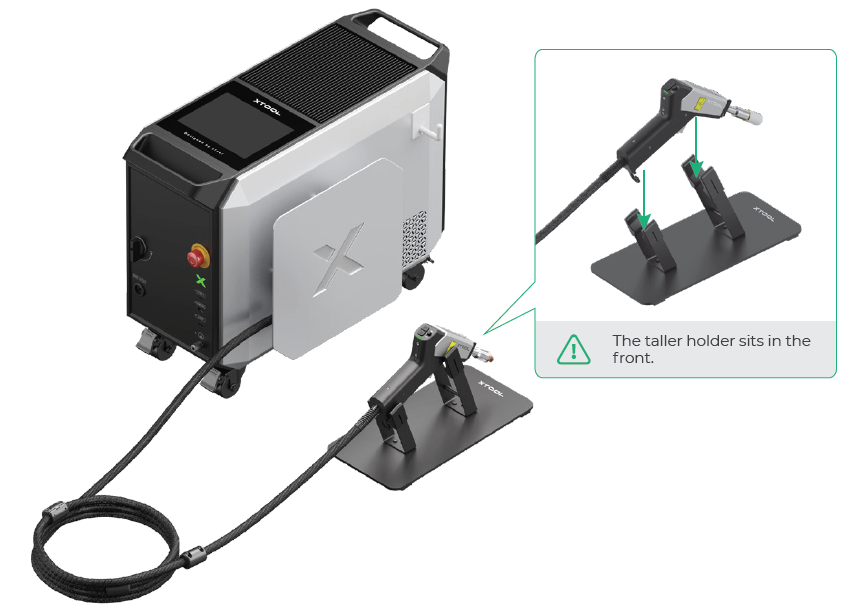

(2) Take the welding head off the main unit and place it on the cradle.

Caution: Do not pull the cable forcefully when taking the welding head off, as this can damage the optical fiber. |

4. Connect the workpiece sensing cable

Insert the connector end into the port for the workpiece sensing cable, and attach the clamp to the worktable for now.

Caution: It is strictly prohibited to attach the clamp to the graduated tube of the welding head. |

Safety interlock loop The workpiece sensing cable is used to connect the main unit with the workpiece, forming a safety interlock loop. The cable clamp needs to be connected to the workpiece before welding. During welding, when the welding head is in contact with the workpiece, the safety interlock loop will be closed and allow laser emission. |

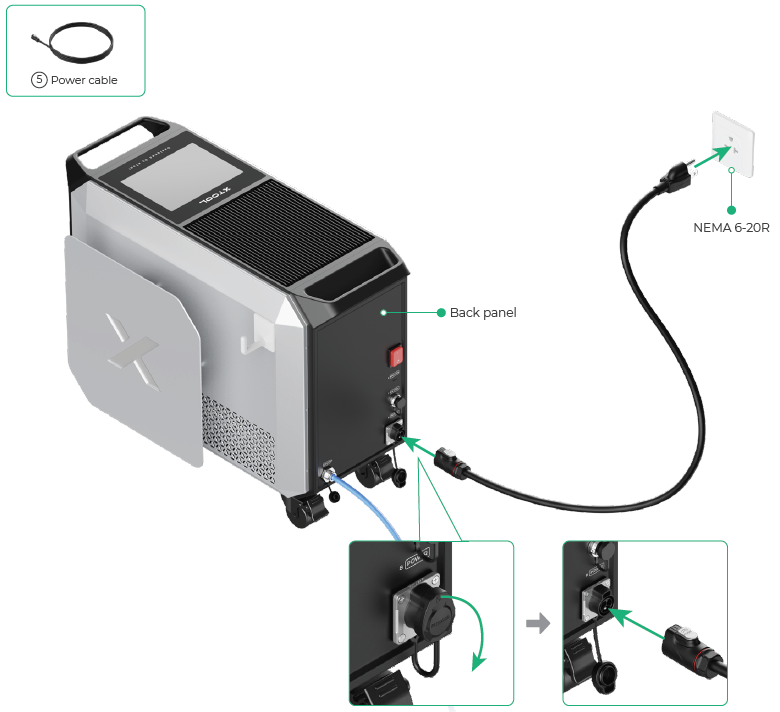

5. Connect to a power supply

Caution: ■ Ensure that the welder is powered separately. Do not use it with other high power equipment on the same circuit. ■ To ensure safety, it is recommended that you install a 20 A air circuit breaker between the power supply and xTool MetalFab Laser Welder 800W. ■ The connection of power cables varies with their standards. The following instructions are for US standard power cables only. Power cables of other standards should be connected in accordance with local electrical codes. |

Insert the connector with a PUSH button to the power port of the main unit, and attach the other end to the power supply.

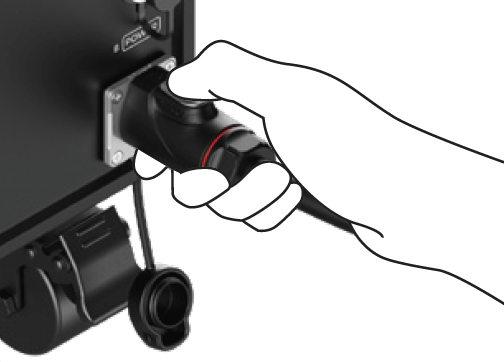

Tips: To remove the connector, press and hold the PUSH button and pull the connector out.

|

Note: For the electrical requirements of other types of power cables, see Power Requirements for MetalFab Products in Different Countries and Regions.

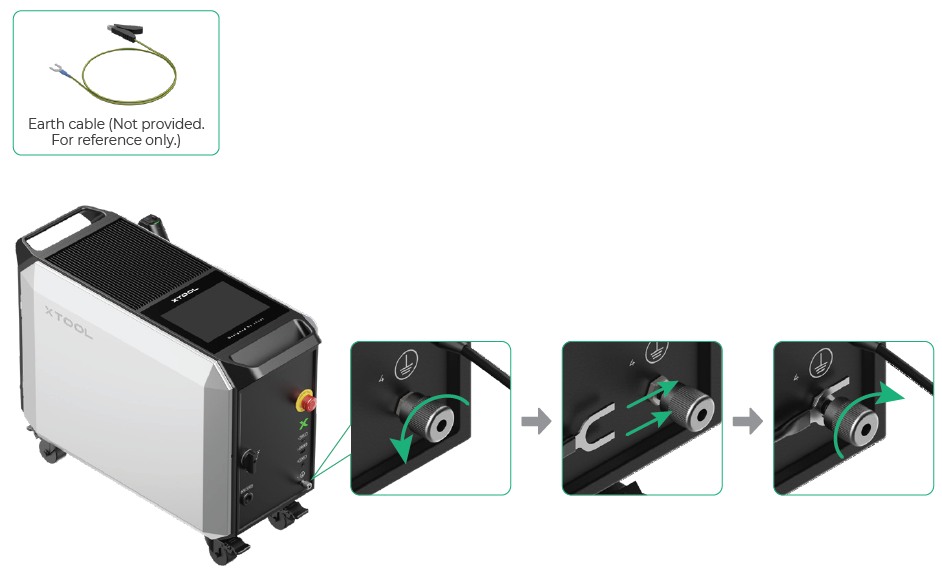

Caution: Ensure that the device is grounded. If the power supply is not grounded, please use an earth cable (not provided) to connect the device to a grounded object.

|

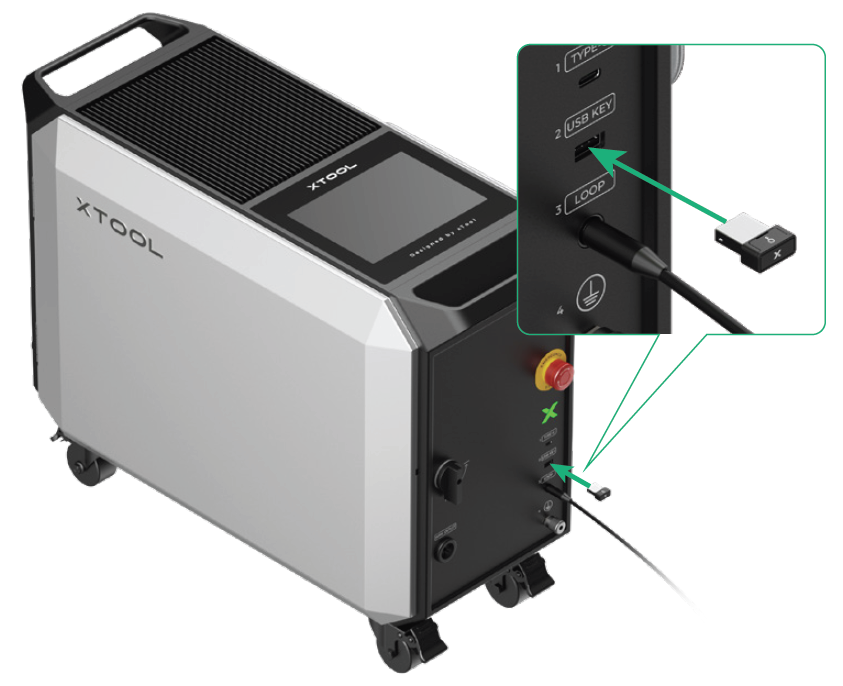

6. Check the emergency stop button

Ensure that the emergency stop button is released. If it is pressed, rotate to release it.

Emergency stop button If an emergency occurs, press the emergency stop button to shut off the laser module and stop laser emission.

After dealing with the emergency, rotate the emergency stop button to release it. |

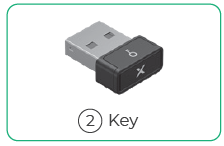

7. Insert the key into its designated port

Note: You can use the key either as an access-control key or a remote interlock connector.

Removing the key can disable the machine's processing and related functions.

For detailed instructions, visit xTool Access Control Key. |

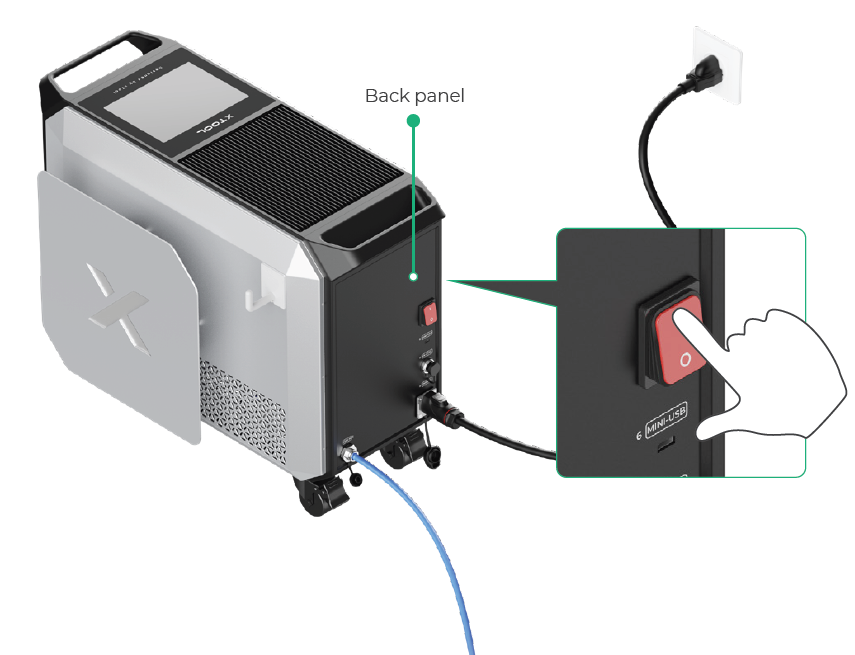

8. Power on

On the back panel of the main unit, turn on the power switch to power on the device.

Unlock the device

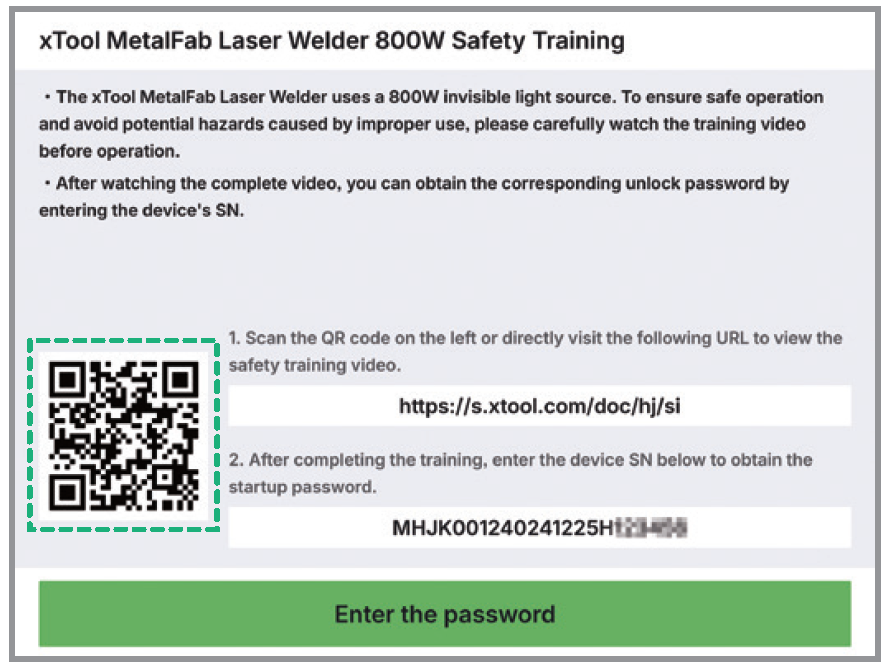

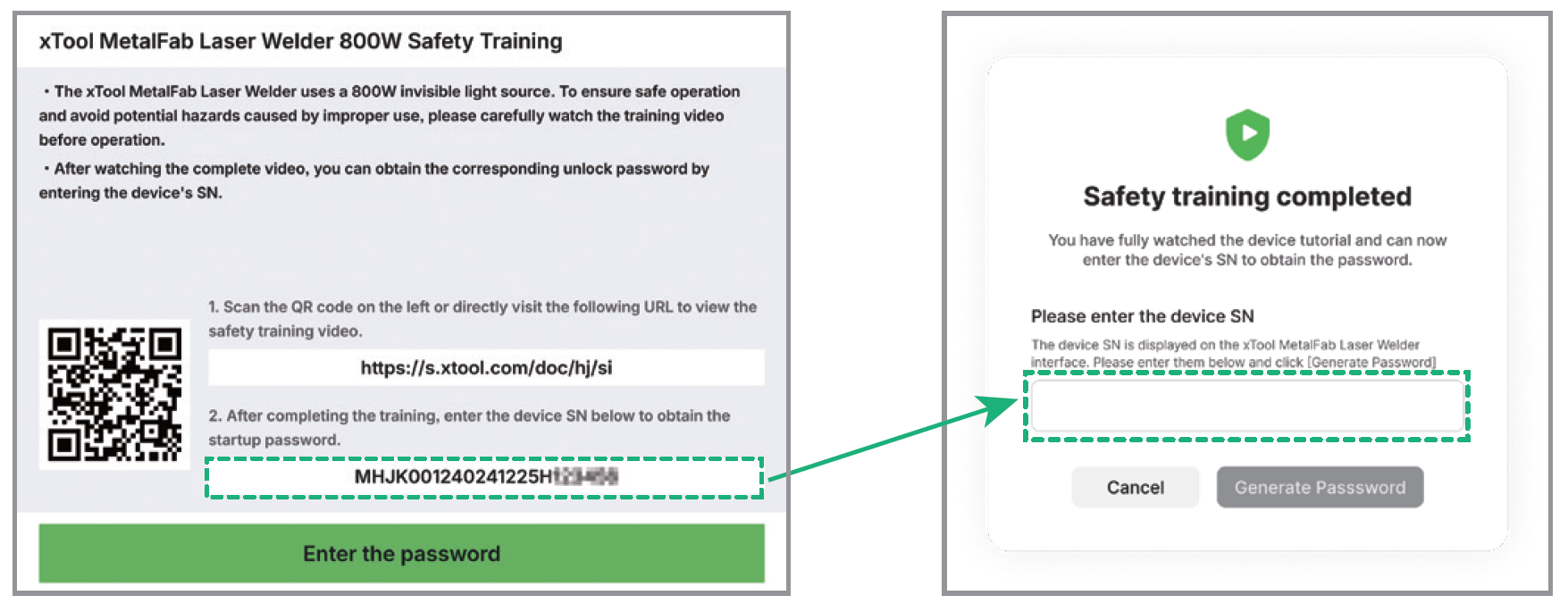

(1) The first time you turn on the device, you will see a QR code displayed on the touchscreen. Scan the QR code or visit s.xtool.com/doc/hj/si to watch the safety training videos.

(2) After watching the video, input the serial number (SN) shown on the touchscreen to the web to generate an unlock password for your device.

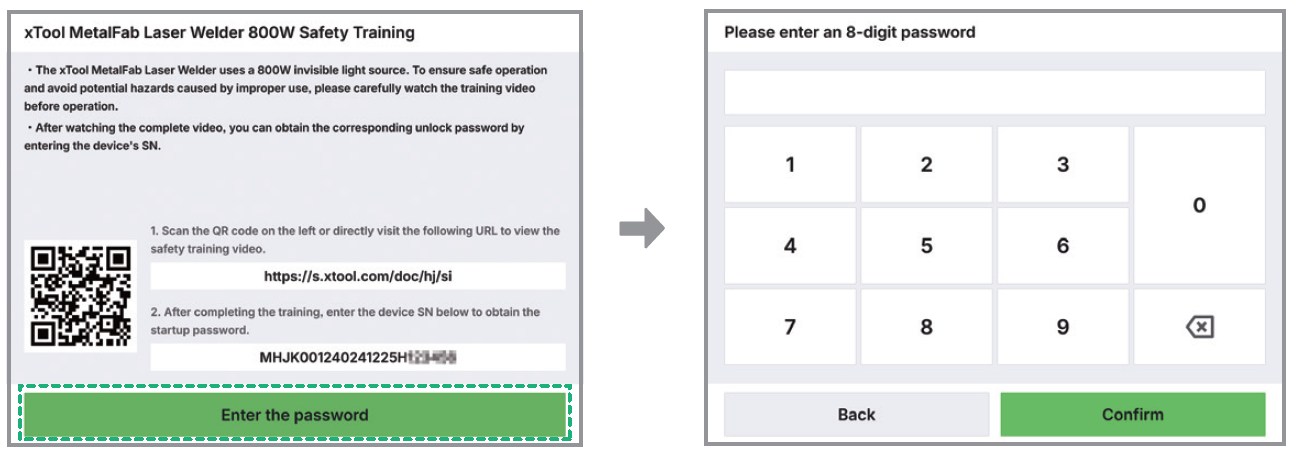

(3) On the touchscreen of your device, tap Enter the password. Then, enter the password generated to unlock your device.

Caution: Ensure that all users watch the safety training videos before using the device. You can access the videos by visiting s.xtool.com/doc/hj/si. |

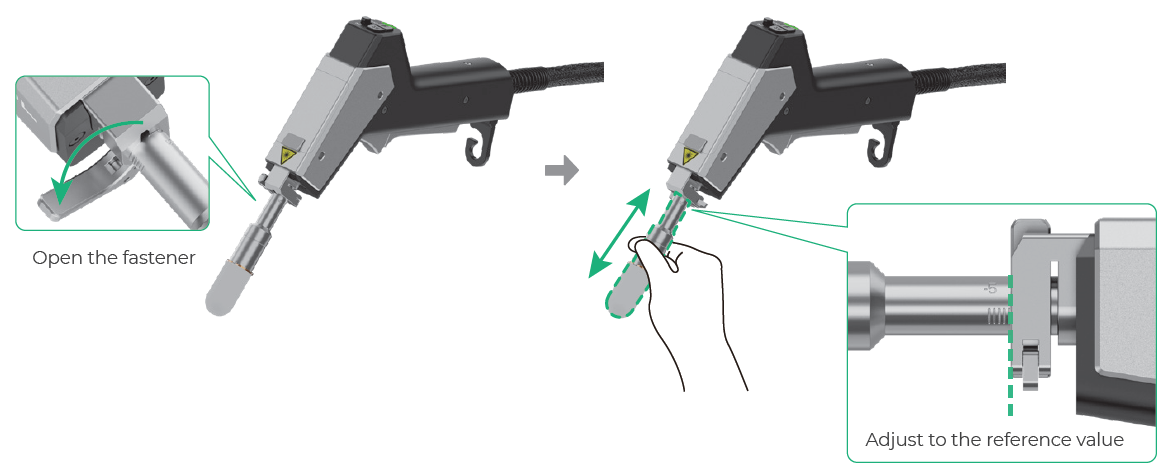

Calibrate the focus for the welding head

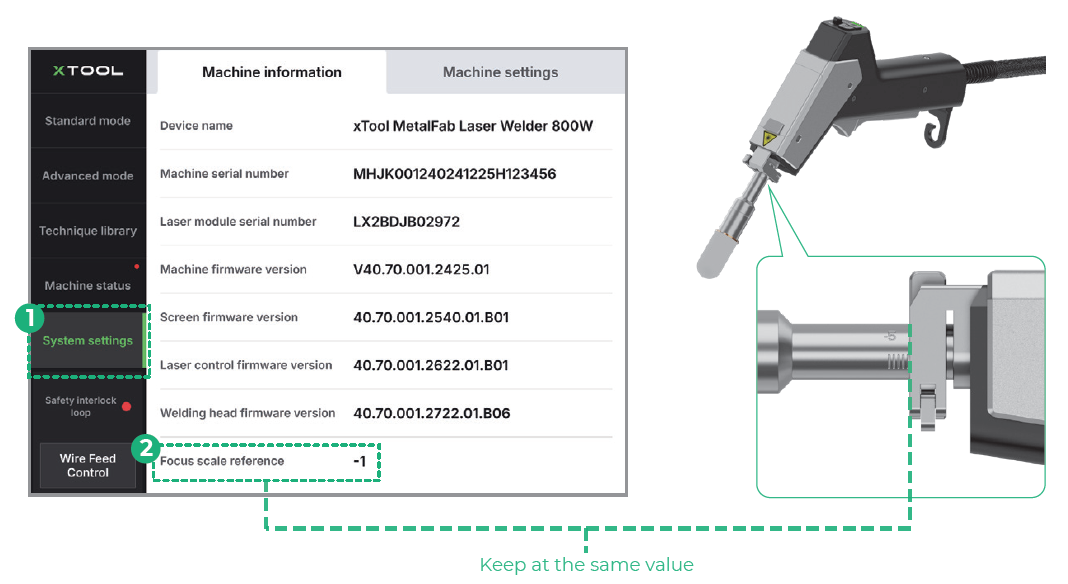

(1) On the home page of the touchscreen, tap System settings and check whether the Focus scale reference is the same as the actual value on the graduated tube. If the values are the same, no calibration is needed; if they are not, go to step (2).

(2) Open the fastener, and push or pull the graduated tube to adjust it to the reference value shown on the touchscreen.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.