Before use

1. Why does the xTool air compressor only produce up to 145 PSI (1.0 MPa)? Is this sufficient for metal cutting?

The xTool air compressor and air dryer are engineered as a compact yet fully optimized solution for metal cutting, unlike bulky industrial systems.

- Performance: While smaller, it delivers continuous pressure above 87 PSI—more than enough for cutting 4-mm stainless steel when paired with the xTool SaveGas nozzle (key to efficiency).

- Filtration: The 3-stage HyperPure air dryer removes 99% moisture and 99.99% oil/dust, ensuring clean, dry air for flawless cuts.

xTool air compressor & air dryer is a cost-efficient, high-performance system designed specifically for precision metal cutting.

2. Can I use the xTool air compressor separately?

No, the air compressor must be used with an air dryer. Without it, moisture, oil, and dust in the compressed air may enter the welding head and air tubes, reducing cutting performance and damaging the equipment.

For this reason, the xTool air compressor is not available for separate purchase.

3. Can I use the xTool air dryer with my own air compressor?

Yes! The air dryer is available for separate purchase (click here to buy).

For optimal performance and safety, the air compressor you prepare must meet the following requirements:

- Rated pressure: ≥ 145 PSI (1.0 MPa)

- Airflow: ≥ 7 CFM @ 87 PSI (200 L/min @ 0.6 MPa) when using the xTool SaveGas nozzle

- Max airflow into dryer: < 14.1 CFM (400 L/min)

- Max pressure: < 181 PSI (1.25 MPa)

- Max air temperature: < 122°F (50°C)

Exceeding these limits may harm the air dryer and affect cutting quality.

4. What are the electrical requirements for the xTool air compressor and air dryer?

Air compressor: 220 V, 10 A, 2200 W

Air dryer:

- EU/UK: 220 V, 1.73 A, 380 W

- US: 110 V, 3.45 A, 380 W

For more details, refer to the Product specifications in User Guide.

5. What is the specification of air tube connections?

M10 quick-connect fitting (10 mm diameter hose), same as the xTool MetalFab.

6. Why does the air compressor make noise during operation?

Noise is generated because the compressor automatically turns on to maintain air pressure. Here’s how it works:

Pressure drop: When air is released, pressure in the tube decreases.

Automatic refill: If pressure drops below 1.0 MPa, the compressor activates to restore it, ensuring a stable air supply.

Motor operation: The noise comes from the motor running during this process.

Note: Small pressure fluctuations below 1.0 MPa are normal and expected.

7. What is the noise level of the xTool air compressor?

About 85 dB when it is generating the air.

8. What is the temperature range of the air outlet of the air dryer?

With ambient temperature of 0°C to 40°C and relative humidity of 50% to 90%, the outlet air temperature maintains within 0°C to 40°C.

During use

1. What should I do if the air volume and pressure are insufficient?

Inspect all tube and pipe connections. If you find any leaks, apply tape to the threaded ends to ensure a secure connection.

If xTool MetalFab CNC Cutter is connected and the xTool software displays an air pressure lower than 0.4 MPa, first verify the air compressor is set to 1 MPa in Fast mode as recommended.

If the settings are correct but pressure remains low, inspect all tube connections for leaks and check the compressor for damage.

2. Is it possible to shorten the tube connecting to the welder?

It is not recommended. A shorter tube may not effectively condense water, which could disrupt airflow to the welder.

3. What should I do if water enters the tube connecting the welder?

If the processing result is poor and water droplets are found on the lens protector, follow these steps to resolve the issue:

1) Stop using the welder's cutting function immediately.

2) Check the air dryer to ensure it is functioning properly.

3) Allow the air dryer to run and continue drying the air.

4) After some time, place a dry piece of cardboard near the welder head nozzle. If the cardboard remains dry, the air dryer is now supplying dry air.

5) Replace the lens protector and resume processing.

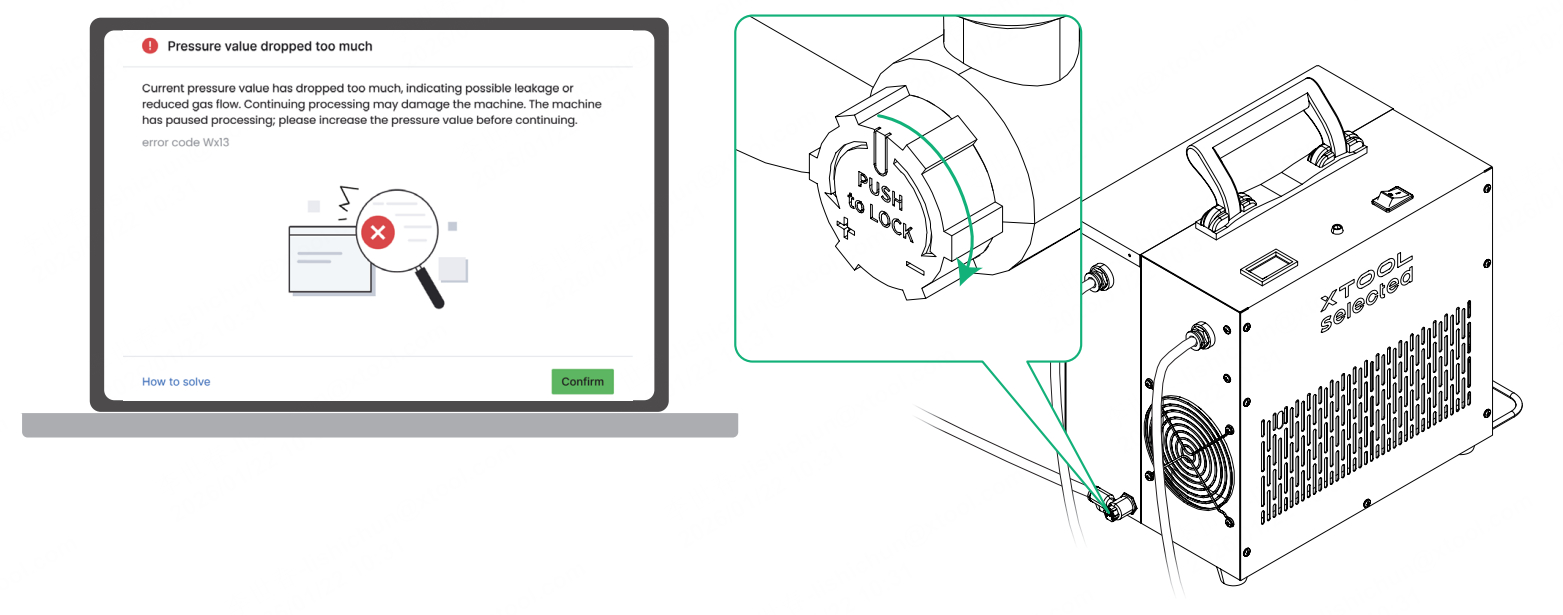

4. A low-pressure alarm is reported when the air dryer is connected to xTool MetalFab CNC Cutter. What should I do?

To address this issue, reduce the flow speed by slightly turning the flow valve knob clockwise from its factory setting. Be careful not to rotate it too far.

5. What should I do if a small amount of oil stains builds up on the lens protector after long-term continuous cutting (e.g., 8 hours)?

The lens protector has a limited lifespan. An oil-stained lens protector may negatively affect dross adhesion. You can wipe the lens protector by using a cotton swab or lint-free cloth dampened with alcohol.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.