Issue description

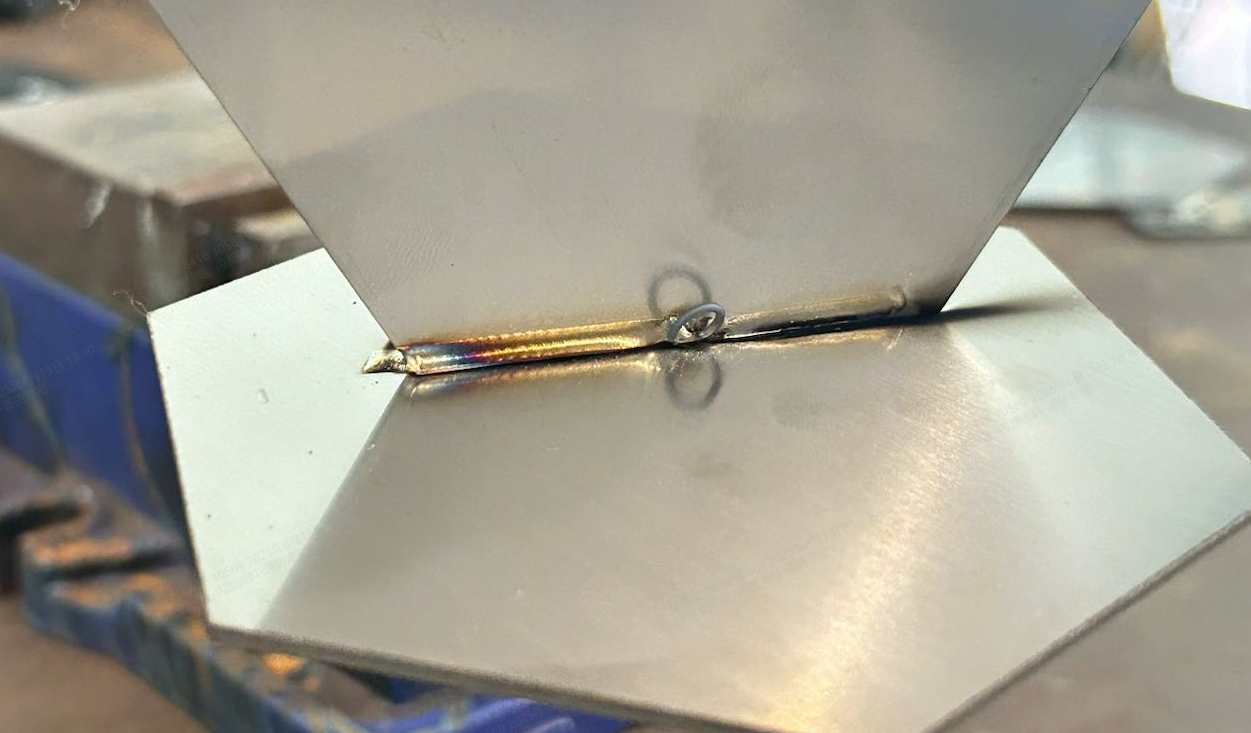

During wire-filled welding, the workpieces melt correctly, but the welding wire fails to melt properly and fill the welding seam adequately.

|  |

Possible causes

Workpiece-related issues

- The surface of the workpiece is dirty (e.g. covered with grease, rust, coatings, or dust), which prevents the wire from effectively fusing to the weld seam.

Welding wire-related issues

- The wire is not seated in the groove of the welding nozzle, so that the laser beams cannot accurately hit the wire and melt it.

- The wire is not extended to the proper length (too long or too short), and thus melts early or late and fails to fill the weld seam properly.

- The wire type does not match the workpiece. For example, the melting point of the wire is much higher than the workpiece.

- The wire feeder fails to feed wire stably and constantly.

Laser-related issues

- The red light spot shifts from the center, which indicates that the working laser is also shifted and thus fails to accurately hit the wire and melt it.

- The laser parameters are not properly set. For example, the laser power is too low or the welding speed is too fast, and thus the laser cannot melt the wire properly.

Troubleshooting procedure

Please follow these steps in order.

STEP 1: Check the workpiece

Check if the surface of the workpiece is clean. If not, clean it with alcohol or acetone and keep it dry.

STEP 2: Check the welding wire

(1) Check if the welding wire is seated in the groove of the welding nozzle. If not, manually pull it into the groove.

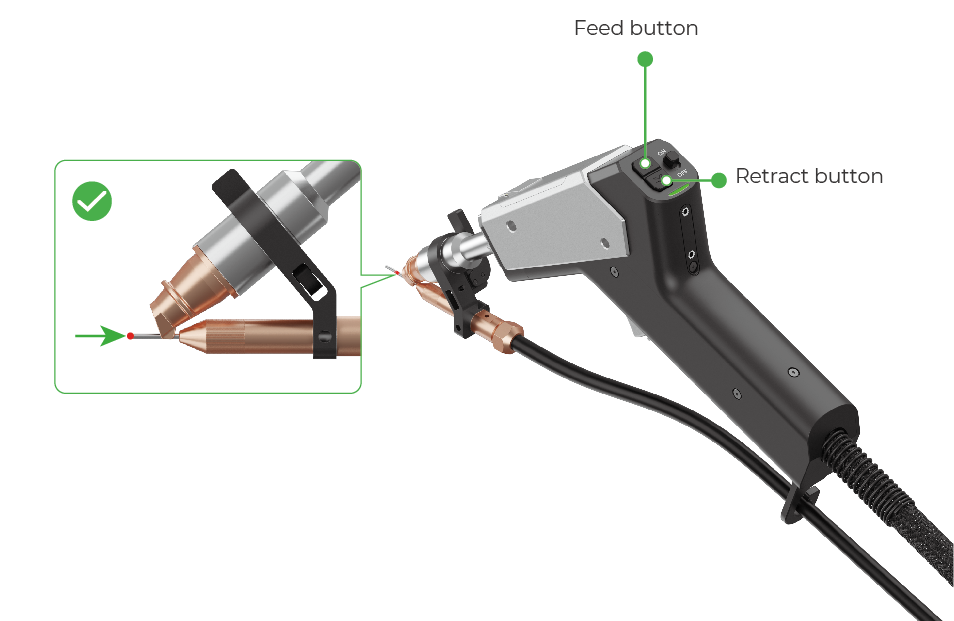

(2) Check if the tip of the welding wire coincides with the red spot emitted from the welding nozzle. If not, press the feed and retract buttons on the welding head to adjust the wire.

(3) Refer to the following table to check if the wire type matches the workpiece. If not, replace the wire.

(4) Check if the wire feeder feeds wire stably and constantly.

For detailed instructions, see “Troubleshoot Erratic Wire Feeding for xTool MetalFab Laser Welder”.

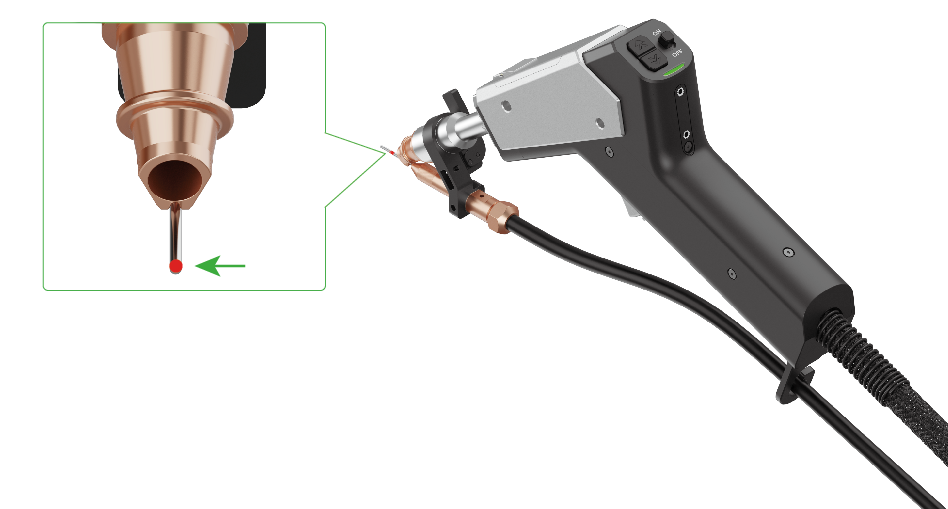

STEP 3: Check the red light spot emitted from the welding nozzle

When the machine is turned on, the welding head emits a red light spot that indicates where the laser beams will hit during laser processing.

Check if the red light spot falls at the center of the welding wire. If not, calibrate

STEP 4: Adjust welding parameters

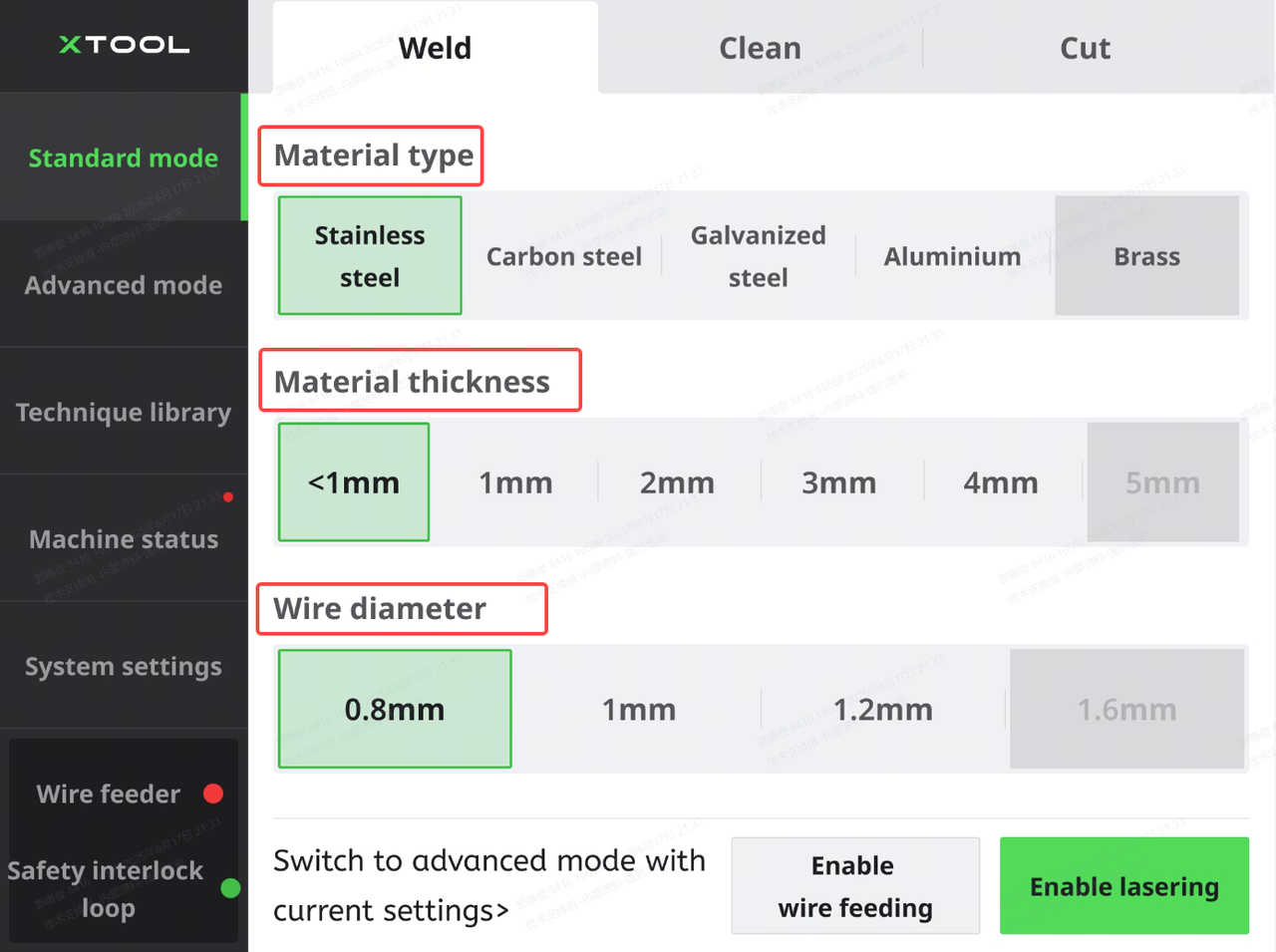

(1) Try Standard mode and use the default settings first.

On the touchscreen, select Standard mode > Weld. Select the material type, material thickness, and wire diameter according to the actual situation.

Then, start laser welding. The machine will automatically use the default settings based on your selection.

Note: If the problem persists, go to the next step.

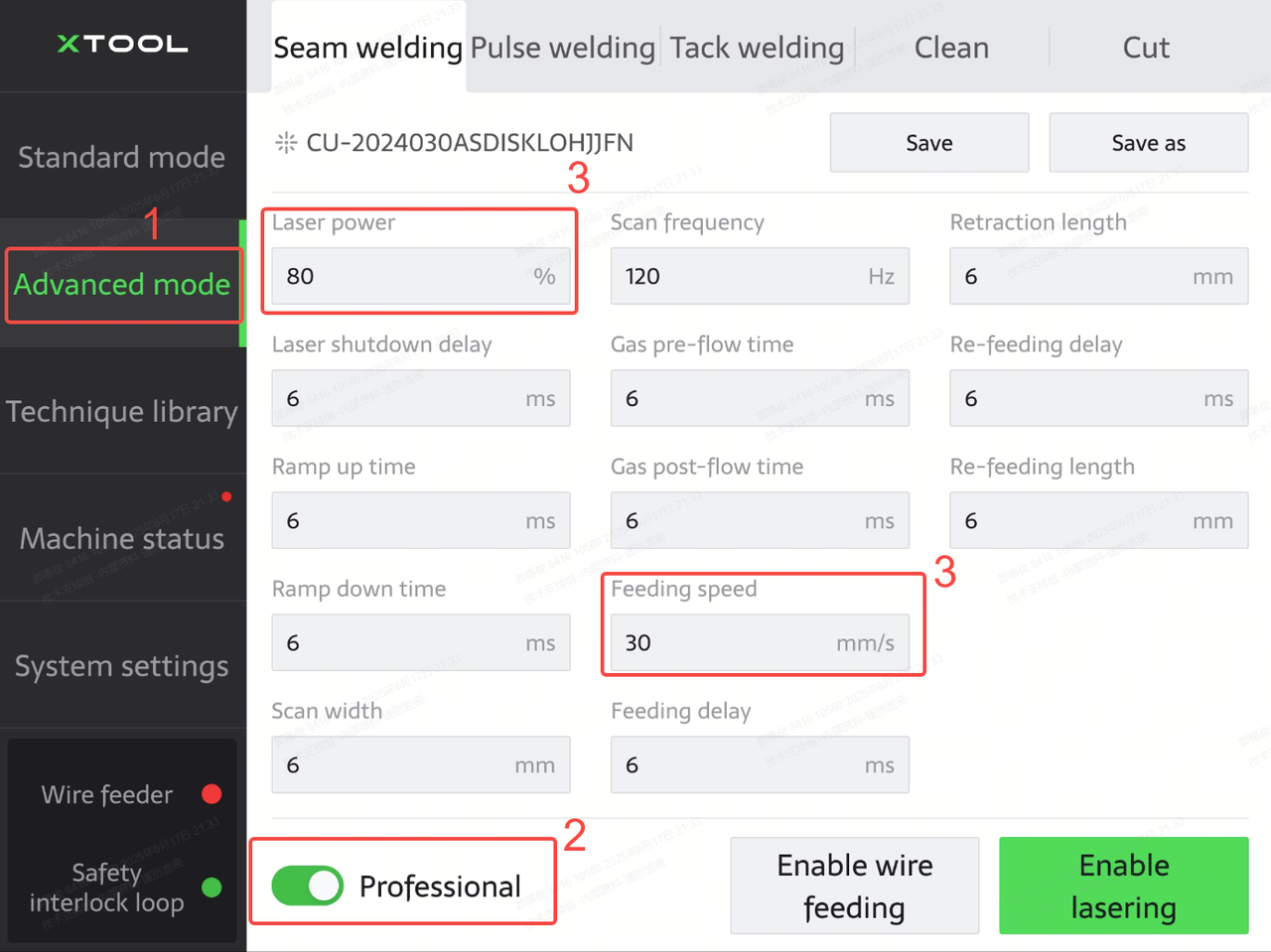

(2) Go to Advanced mode and adjust welding parameters.

On the touchscreen, tap Advanced mode, and turn on Professional. Then, increase Laser power and decrease Feeding speed.

Still experiencing issues?

Should the issue persist after completing the preceding steps, submit a ticket via the "Submit a Ticket" button in the "Help Ticket" section below. The standard response time for xTool Customer Service is one business day.

For a prompt resolution, please include the following details:

- Issue description: A detailed explanation of the observed problem.

- Video evidence: Attach a video demonstrating the issue, where applicable.

- Troubleshooting performed: Any troubleshooting steps you have already attempted, along with their results.

This information is crucial for xTool technical support engineers to provide timely assistance.

Documentation feedback

Help improve this content by providing feedback. If this content did not meet your requirements, select "No" in the "Was this page helpful?" section below. Include specific details about what was unclear or missing in the pop-up suggestion box. Feedback submissions are reviewed by xTool technical writers to enhance future documentation.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.