Issue description

When operating your xTool laser device with SafetyPro™ Air Purifier 2 (AP2), you may experience ineffective air purification where persistent odors or a burning smell leak from your laser device, or visible smoke escapes.

If you encounter this issue, please follow the troubleshooting steps outlined in this guide.

Possible causes

- Filter blockage

- Assembly issues:

- Front cover not properly installed;

- Filter not installed correctly;

- Missing filters;

- Improperly installed smoke exhaust pipe;

- Filter issues:

- Rolled edges on the anti-leak pads

- Damaged filters

- Broken smoke exhaust pipe

- Incorrect settings

- Use of a Riser Base (class 4) without closing its front door panel

- Incorrect fan speed due to outdated P2S firmware version

Troubleshooting

1. Check for filter blockage

- Set the airflow level to level 4 and let AP2 run for 2 minutes.

- Observe the fault indicator:

- If it is solid red, smoke leakage is caused by filter blockage. Address the issue by referring to Troubleshoot "Exceptions Occur" (Error Code: M9039 S4) on xTool AP2.

- If it is not solid red, proceed to the next step.

2. Check your AP2 installation

- Verify the filter installation order:

- Ensure all filters are correctly installed and none are missing or damaged.

- Correct installation sequence from bottom to top: "5 Ultra HEPA Filter" > "4 Ultra Dense Carbon Mesh Filter" > "3 Activated Carbon Filter" > "2 Medium Efficiency Filter" > "1 Pre-filter" > "0 Cyclone"

- Ensure that all filters are pushed in until they align with the white line for alignment.

- Check the anti-leak pads:

- Inspect the anti-leak pads around the airflow inlet and on the edges of all filters for any damage or deformation, including compression and rolled edges.

- If any, please contact xTool Customer Service for further assistance.

Anti-leak Pads Around Airflow Inlet |

Anti-leak Pads on the Edges of Cyclone |

Anti-leak Pads on the Edges of Filters |

3. Check the front cover: Ensure that the front cover is fully installed. Improper installation may not trigger a warning and cease AP2's normal operation, but this compromises the device's closed space, thus resulting in odor and smoke leaks.

|

|

3. Check the smoke exhaust pipe

- Ensure that the smoke exhaust pipe is properly installed, especially with S1 and P2 Series.

- For S1

- Ensure the flange plate on the back of the laser device for the smoke exhaust pipe connection is tightly secured with its 4 screws.

- Ensure the pipe has not been detached or loosened from the flange plate as they are glued together during manufacturing.

- If so, this compromises the closed space design for ventilation. Please secure them with tape to guarantee a complete enclosure or replace the structure if necessary. For a replacement, contact xTool Customer Service.

- For P2 Series:

- Use a pipe clamp (included in both the P2 series package and AP2 package) to secure the smoke exhaust pipe to the flange plate for ventilation. As P2 series laser devices use a soft exhaust pipe that cannot be directly secured to, without the pipe clamp, smoke may leak from the pipe.

Pipe Clamp in AP2 Package

- Adjust AP2's fan speed based on the material being processed: When working with materials like acrylic, if noticeable odors occur, it is advisable to moderately reduce the fan speed so that activated carbon has sufficient time to neutralize them. For materials that generate significant dust, using a higher speed setting is recommended to quickly exhaust the particles.

2. Check for any damage to the exhaust pipe.

Minimize the length of the pipe to check for any exhaust pipe damage. Replace the pipe if necessary.

4. Adjust AP2 settings

- When using multiple accessories that create an open environment (e.g., Riser Base, Conveyor, Conveyor Feeder, Slide Extension):

- For xTool accessories that cannot form a closed space, this may allow smoke and odor to escape.

- Set the air purifier to manual mode by tapping its "Airflow switch button" and run it at maximum power to reduce residual smoke.

- For Riser Base users:

- For Auto mode: Extend the air purifier's delay shutdown time by about 30 seconds in XCS.

- For manual operation: Maintain AP2 running for a short time after processing.

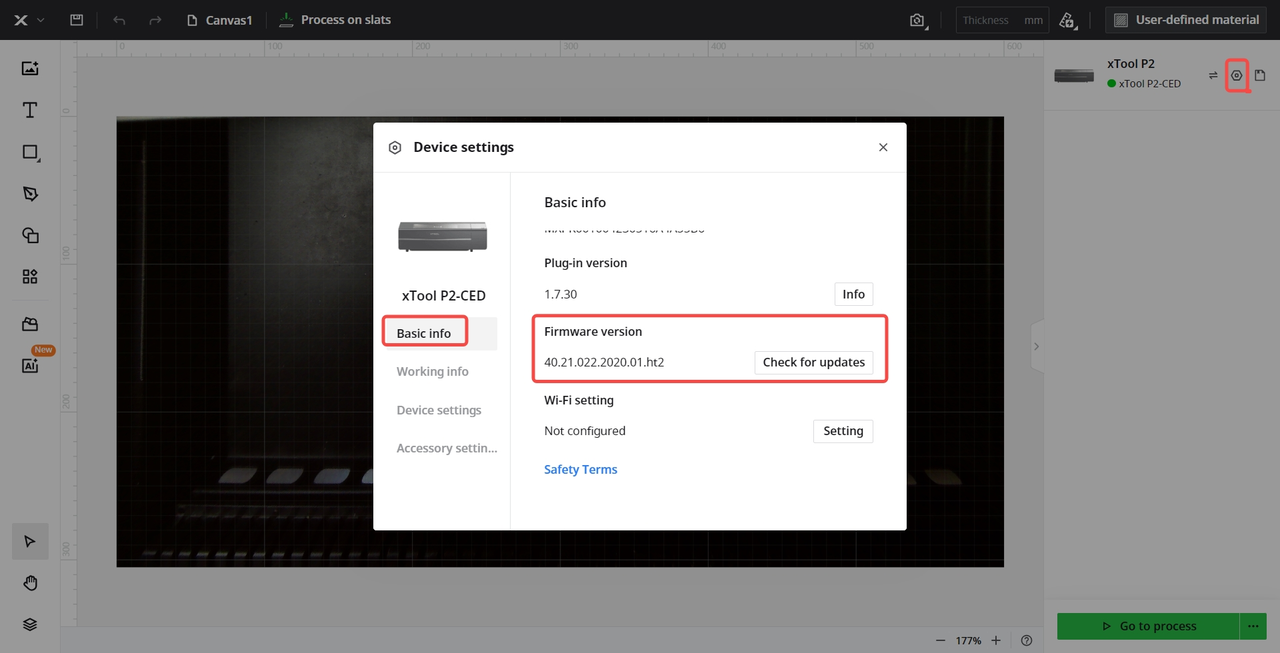

- For P2S users:

- Automatic mode: Ensure that P2S firmware version is the latest. After connecting to AP2, P2S adjusts its fan speed based on AP2 airflow level.

- Manual mode:

- AP2 airflow levels at 1–2: Set P2S fan speed to 30%.

- AP2 airflow levels at 3–4: Set P2S fan speed to 50%.

- Automatic mode: Ensure that P2S firmware version is the latest. After connecting to AP2, P2S adjusts its fan speed based on AP2 airflow level.

AP2 Airflow Level Setting |

P2S Fan Speed Setting |

Still need help?

If the problem persists, please create a ticket by clicking the “Submit a Ticket” button in the “Help Ticket” section below. Our service team will get back to you in 1 business day via email.

Help us improve

If this article or video doesn't effectively assist you in resolving the issue, please let us know by clicking the “No” button in the “Was this page helpful?” section below, and leave your feedback in the pop-up suggestion box. Our knowledge base team will review it and consider it for future updates.

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.