I'm in the(well, my wife is) 1:12 scale miniature business, so we're making small things happen. I need to design some picture frames which can be cut out on my P2S. I created a design using compound vectors and it ‘sort of’ came out. I think I just need some fine-tuning advice from the folks here. Let me tell you a little more about it:

I wanted to build confidence first by making a simple picture frame, which would have steps down from the outer edge of the frame, down to the area where the picture would be located - think of stairs. So, I created my initial rectangle 70mm x 50mm. I then applied an internal offset of 1mm, selected both and create a compound vector. I copied this vector, reduced it's size by 2mm on each side, so 68mm x 48mm. I copied that, reduced by two, so I had a total of 4 ‘steps’. I then nested them inside one another, and set a different engraving power and speed for each one, so that the outermost would be the least engraved, and the innermost would be deepest. Finally, I created a rectangle to cut the inside out(where a picture would go), and lastly, I created a cut rectangle 4mm larger than my first one, so 74mm x 54mm. I did not concern myself with kerf offset, as this was mostly a test to see what would happen after pressing START.

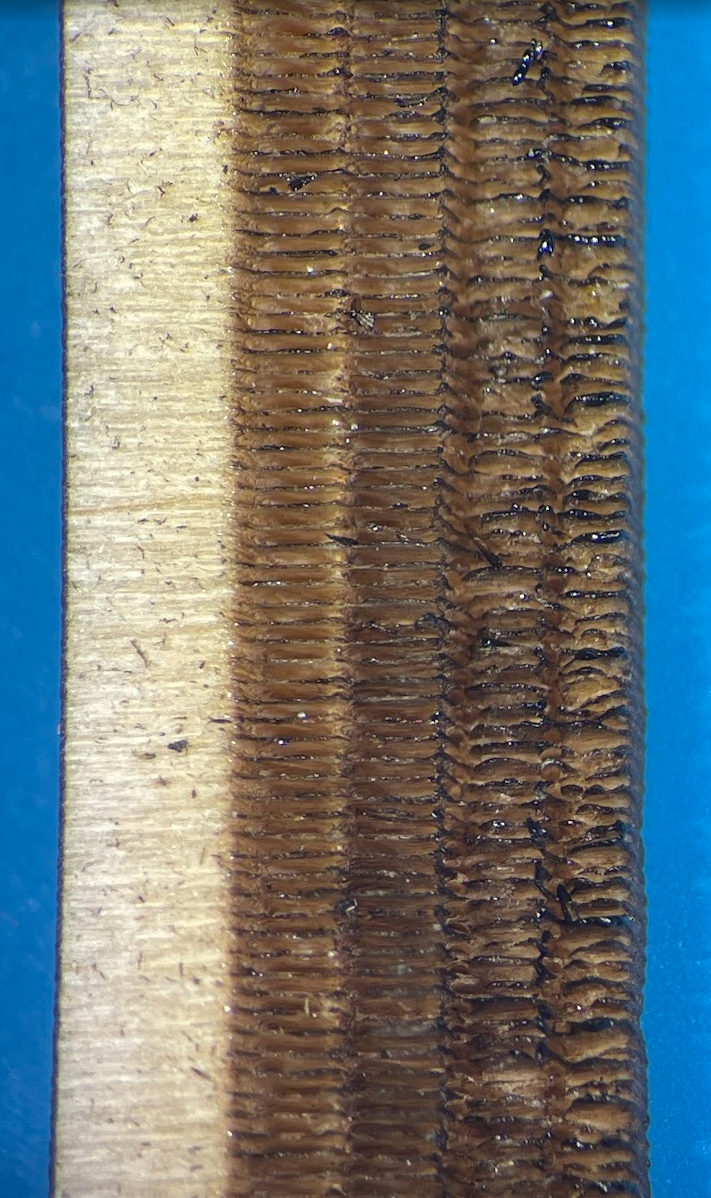

Surprisingly, everything sort of came out. It definitely stepped down 4 times, but the stepped surfaces are actually comprised of little lines - it's crazy. Have a look at the closeup picture, and tell me: what did I do wrong? This is 3mm solid Basswood, btw. Also, the reason those little sections are so mangled on the close up, is because I took a toothbrush to it first.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.