Overview

xTool conveyor feeder is designed for xTool laser processing machines to feed materials in conveying mode, allowing the machines to process materials that are too long for them. With xTool conveyor feeder, you can create larger and cool works.

#1 Preparations

Specification

Applicable to | Maximum material length supported | Maximum material thickness supported |

xTool P2 series | 3 m | 14 mm |

List of items

Conveyor feeder |

Conveyor rail |

Conveyor rail riser |

Conveyor rail riser block |

Motor cable clamp | .png) Short rail |

Material pressing rod |

Cable tie |

Cable tie holder | .png) Level adapter |

Screw M3*8 |

Screw M4*6 |

.png) Screw M4*20 | .png) Hex key |

.png) User manual | .png) Quick start guide |

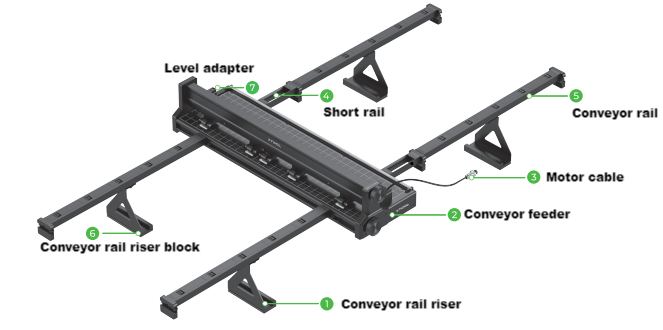

Meet your conveyor feeder

Assemble the conveyor feeder

Note: Steps for installing the conveyor feeder on the xTool P2 series are similar. This document uses xTool P2 as an example.

💡 Tips: It is recommended that you read Appendix 1 - Tips for using the product before using the product.

.png)

For materials of thickness 0<H ≤ 8 mm

To process materials of thickness 0<H ≤ 8 mm, assemble the conveyor feeder as follows.

.png)

- Press and open the front and rear door panels of xTool P2.

.png)

.png)

- Place the baseplate of xTool P2 at level 2a to help assemble the conveyor feeder.

.png)

💡 Tips: DO NOT put the baseplate into xTool P2 totally. You need to keep a distance of 10cm from the left front corner of the riser base.

.png)

- Prepare the screws M4*20.

Place the conveyor feeder on the baseplate of xTool P2. Tighten screw A first, but do not tighten it fully.

.png)

- Tighten screw B.

.png)

- Tighten screw A fully.

.png)

Prepare the conveyor rails, conveyor rail risers, conveyor rail riser blocks and screw M4*6.

.png)

- Install the conveyor rail riser block to the bottom of the conveyor rail riser and tighten the screw clockwise.

.png)

7. Turn over the conveyor rail.

.png)

- Place the conveyor rail riser on the middle part (on the third section of the conveyor rail) of the conveyor rail.

.png)

9. Determine the position of the riser on the conveyor rail and tighten the screw on the riser.

.png)

10. Assemble another conveyor rail in the same way.

.png)

Prepare the conveyor rails, conveyor rail risers, conveyor rail riser blocks, screw M4*6 and short rails.

.png)

11. Fit the other rail risers and their blocks on the other two conveyor rails in the same way.

.png)

12. Install the short rails and conveyor rails, and tighten the screws.

.png)

Assemble another conveyor rail in the same way.

.png)

13. Put two conveyor rails into the groove of the conveyor feeder.

.png)

14. Slide the conveyor rails left and right according to the width of the material to be processed.

.png)

.png)

15. Determine the position of the conveyor rails and tighten four screws (M4*6) to the conveyor feeder..png)

16. Peel off the tape to stick the cable tie holder on the back of xTool P2 (right side of the smoke exhaust pipe).

.png)

.png)

17. Insert the cable tie into the cable tie holder.

.png)

18. Arrange the smoke exhaust pipe with the cable tie holder, and make it not block the conveyor rails.

.png)

19. Fit the other two conveyor rails on the other side of the conveyor feeder.

Note: Fit the conveyor rails with short rails on this side, or they may be damaged due to the incorrect position.

.png)

💡 Tips: Ensure that the width between the rails is the same on both the left and right sides of the conveyor feeder.

.png)

20. Assembly completed!

For materials of thickness 8 ≤ H ≤ 14 mm

To process materials of thickness 8 ≤ H ≤ 14 mm, assemble the conveyor feeder as follows.

.png)

- Press and open the front and the rear door panel of xTool P2.

.png)

.png)

2. Place the baseplate of xTool P2 at level 2a to help assemble the conveyor feeder.png)

💡 Tips: DO NOT put the baseplate into xTool P2 totally. You need to keep a distance of 10cm from the left front corner of the riser base.

.png)

3. Assemble the level adapter and screws M3*8 on the conveyor feeder and tighten the screws clockwise.

.png)

⚠️ Put the screw on the first and third holes (count from the left) of the level adapter.

- Prepare the screw M4*20.

.png)

Place the conveyor feeder on the baseplate of xTool P2. Tighten screw A first, but do not tighten it fully.

.png)

- Tighten screw B.

.png)

- Tighten screw A fully.

.png)

Prepare the conveyor rails, conveyor rail risers and screw M4*6.

.png)

- Turn over the conveyor rail.

.png)

- Put the conveyor rail riser on the middle of the conveyor rail. (on the third section of the conveyor rail)

.png)

.png)

- Make sure the position of the conveyor rail riser and put it on the conveyor rail, then tighten the screw clockwise.

.png)

10. Assemble another conveyor rail in the same way.

.png)

11. Prepare the conveyor rails, short rails, screw M4*6 and conveyor rail risers.

.png)

12. Fit two conveyor rails in the same way.

.png)

13. Install the short rails and conveyor rails, and tighten the screws.

.png)

Assemble another conveyor rail in the same way.

.png)

14. Find the groove in the conveyor feeder and insert two conveyor rails into it.

.png)

15. Move the conveyor rails left and right according to the width of materials.

.png)

.png)

16. Tighten the conveyor rails to the conveyor feeder with four screws.

.png)

17. Peel off the tape of the cable tie holder and stick to the back of xTool P2. (right side of the smoke exhaust pipe)

.png)

💡 It is recommended that you stick the cable tie holder and wait for 24 hours before using it.

18. Insert the cable tie to the cable tie holder.

.png)

19. Arrange the smoke exhaust pipe and make it not block the conveyor rail.

.png)

20. Fit the other two conveyor rails on the other side of the conveyor feeder.

Note: Fit the conveyor rails with short rails on this side, or they may be damaged due to the incorrect position.

.png)

💡 Tips: Ensure that the width between the rails is the same on both the left and right sides of the conveyor feeder.

.png)

21. The assembly of the conveyor feeder completed!

Use the conveyor feeder

- Connect the conveyor feeder to your device.

.png)

Peel off the tape from the back of the cable clamp. Stick the cable clamp on the top of the right guide rail panel (at a distance of 10 cm from the motor cable port).

.png)

.png)

Arrange the motor cable around the cable clamp and make it not block the conveyor rails. Then connect the motor cable to the port.

.png)

- Place a material

Turn the upper knob anticlockwise to raise the pinch rollers and place a material in.

.png)

Put the material to be processed in the conveyor feeder.

.png)

💡 Tips: Align the material with the grids on the conveyor feeder and convey the material to the device, so that the material is parallel to the conveying direction.

.png)

Turn the upper knob clockwise to lower the pinch rollers to press the material in place, so that it won't slip or run away during processing.

For the pressure level, refer to "Appendix 2 - Pressure levels recommended for common materials".

You can rotate the lower knob to slightly adjust the position of the materials, if needed.

.png)

💡 Here is the processing position of laser module:

.png)

- Power on the device and connect it to XCS

Connect to the power supply that on the back of xTool P2 and turn on the power switch.

.png)

.png)

Power on the device and connect it to XCS.

💡 Tips: For details about how to use XCS, visit support.xtool.com. You can join the xTool community at community.xtool.com to obtain more tutorials, tricks and tips, and creation inspiration.

.png)

You can visit Unboxing xTool P2 Conveyor Feeder to find the tutorial video.

#2 Start processing with XCS on your computer

STEP 1 Connect the xTool P2 to XCS

Note: After connecting xTool P2 Series to XCS using a USB cable, you can connect in Wi-Fi or IP mode. Whichever way you choose, you need to connect it to your computer with the USB cable first. After connecting your device to XCS in Wi-Fi or IP mode, you can search for your device on XCS next time without USB connection.

💡 Tips: For details about how to use XCS, visit support.xtool.com. You can join the xTool community at community.xtool.com to obtain more tutorials, tricks and tips, and creation inspiration. You can visit Unboxing xTool P2 Conveyor Feeder to find the tutorial video.

STEP 2 Select the processing mode and material name

Note: If you can't find your material in the list, you can click More xTool materials to search among more materials in the Material EasySet Library. If you still can't find the name of your material, you can select User-defined material.

Note: After you select a material from the material list or Material EasySet Library, the software will automatically set parameters for laser processing. The default settings apply to xTool materials. You can adjust the settings based on your needs.

Note: The recommended parameter settings can achieve the best results only when using xTool's materials. If you are using materials from third parties, it is recommended that you conduct a material test array on your own first to obtain the desired effects and parameters. Meanwhile, make sure that the materials are free from moisture or contamination, which may greatly affect the results.

STEP 3 Measure the distance of the material

Note: When automatic measurement results in significant errors or fails entirely, please consult Manually Measure the Focal Distance for xTool P2 Series for manual measurement of the focal distance.

STEP 4 Shoot the background

icon. You can choose to refresh background or take a close shot.

icon. You can choose to refresh background or take a close shot.

STEP 5 Edit objects and set parameters

Note: Don't put your pattern on the red area, but on the green area.

|

STEP 6 Start processing

Appendix 1 - Tips for using the product

About the pinch rollers

- Do not set the pressure of the pinch rollers too high, or the conveyor feeder may fail to work properly.

- Set the pressure of the pinch rollers according to the material to be processed. For details, see "Appendix 2 - Pressure levels recommended for common materials".

- Cover the pinch rollers with the material fully. If the material is close to the edge of pinch rollers, interference is caused between the conveyor feeder and pinch rollers.

.png)

About the conveyor rails

- When you process a soft and thin material (such as kraft paper and cloth), you can place the processing rod on the material to hold it in place.

- Place the conveyor rails parallel to the conveying direction of a material, when possible.

- Add conveyor rails according to the length of the material to be processed. Make sure that the part of a material hung in the air is no longer than 30 cm.

To use more conveyor rails, you need to purchase them. You can visit xtool.com to purchase them.

- Adjust the distance between the rails according to the width of a material to be processed. Make sure that each part of the material is evenly pressed, when possible. Otherwise, material distortion may be caused and thus pattern deformation is caused.

About materials

- Use flat materials.

- Make sure that the edges of materials are not warped.

About cleaning

- If there are many residues under the pinch rollers (such as wood chips), you can turn over the conveyor feeder, and clean the pinch rollers with a brush while turning the knob.

.png)

- If the smoke produced from the materials and short rails can't emit in time and cause the baseplate dirty. You can clean it with the cleaning cloth and alkaline cleanser.

.png)

Others

- Before you use the conveyor feeder, arrange the connection cables, power cables, and other items that may block the feeding of materials.

- The distance between the pinch rollers and the working area is 20 cm. Ensure the length of the material is at least 20 cm longer than that of the pattern to be processed. Otherwise, the material can't return when the processing is completed.

.png)

Appendix 2 - Pressure levels recommended for common materials

You can find the pressure level window from the middle of the conveyor feeder (on the back of the middle pinch roller).

.png)

💡 Tips: The color you see in the pressure level window indicates the pressure level.

Material name | Thickness | Pressure level |

Plywood | 3 mm | |

Plywood | 6 mm | |

Plywood | 9 mm | |

Plywood | 14 mm | |

Acrylic | 3 mm | |

Acrylic | 7 mm | |

Acrylic | 12 mm | |

Fiberboard | 3 mm | |

Fiberboard | 6 mm | |

Fiberboard | 12 mm | |

EVA board | 5 mm | |

EVA board | 10 mm | |

Felt board | 5 mm | |

Felt board | 9 mm | |

Cork board | 12 mm | |

Kraft paper | 300 g |

After-sales services

If your problem is still unsettled, contact us at support@xtool.com.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)