Technically, the positioning is more precise when it’s near the camera. Due to the placement position of the M1 camera, you might need some tips if you want to place the material properly.

Placement

1.It would be better to process on the baseplate, and not remove the baseplate.

2.If you’re engraving or cutting a small material, place it on the center or upper part of the baseplate.

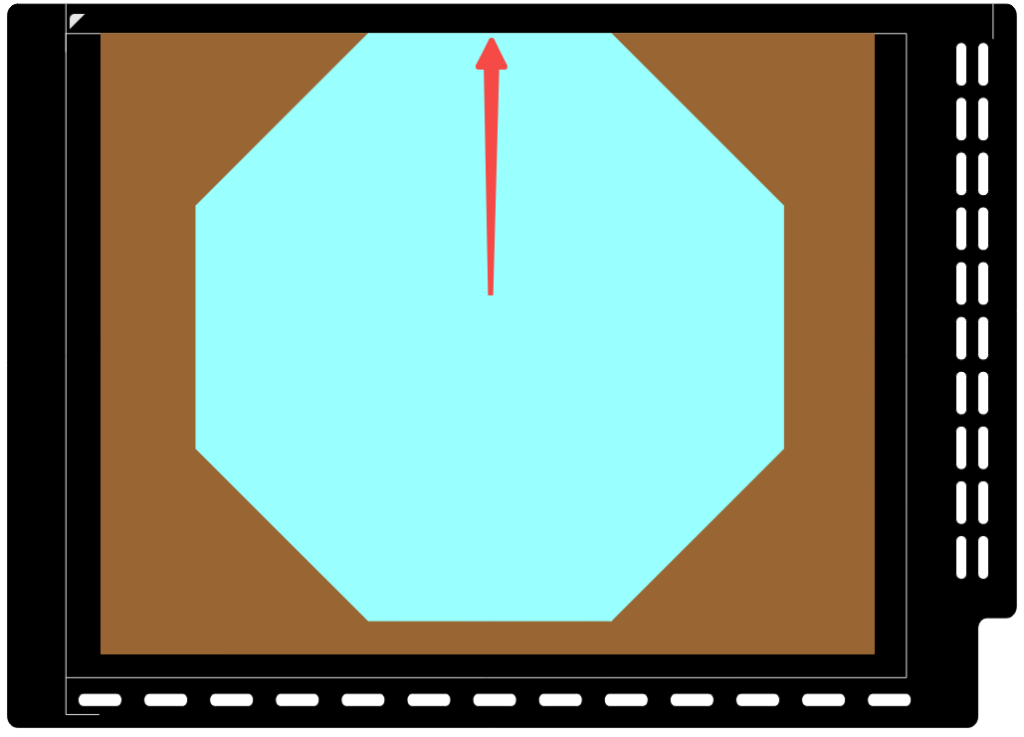

3.If you’re engraving a big area, it is better to place the pattern on the upper center.

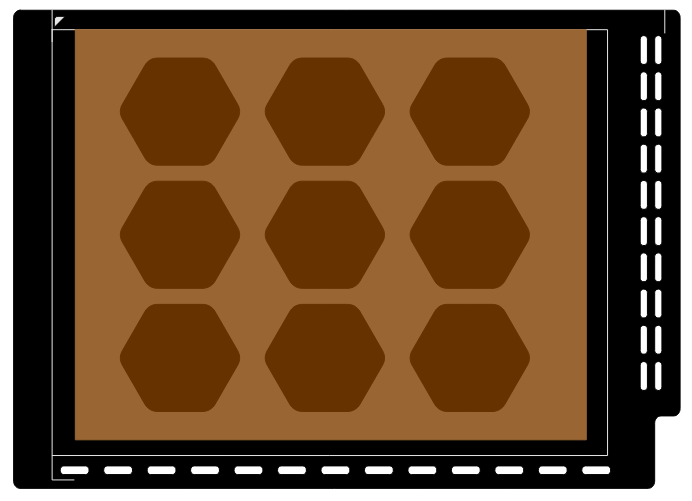

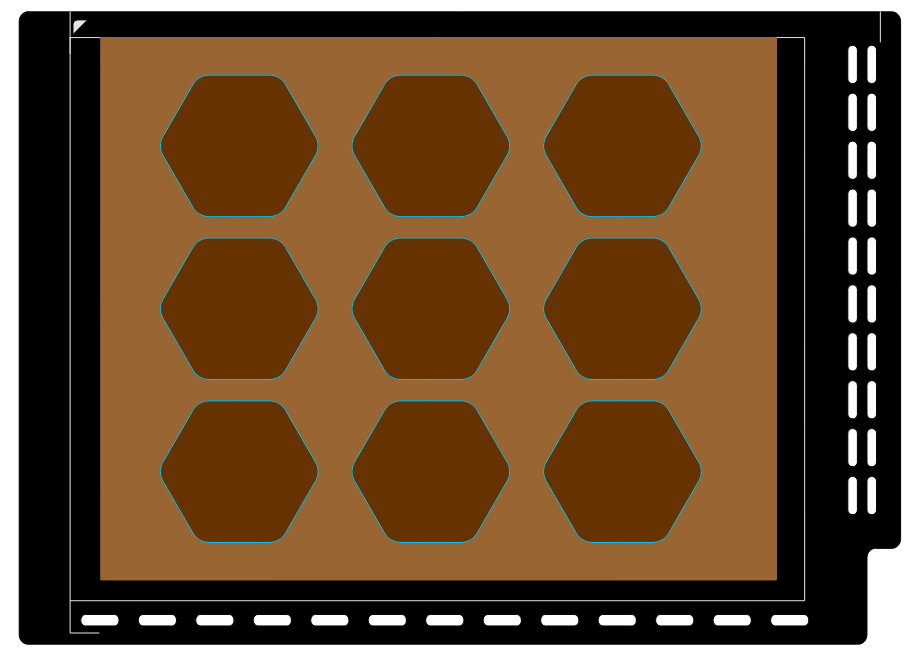

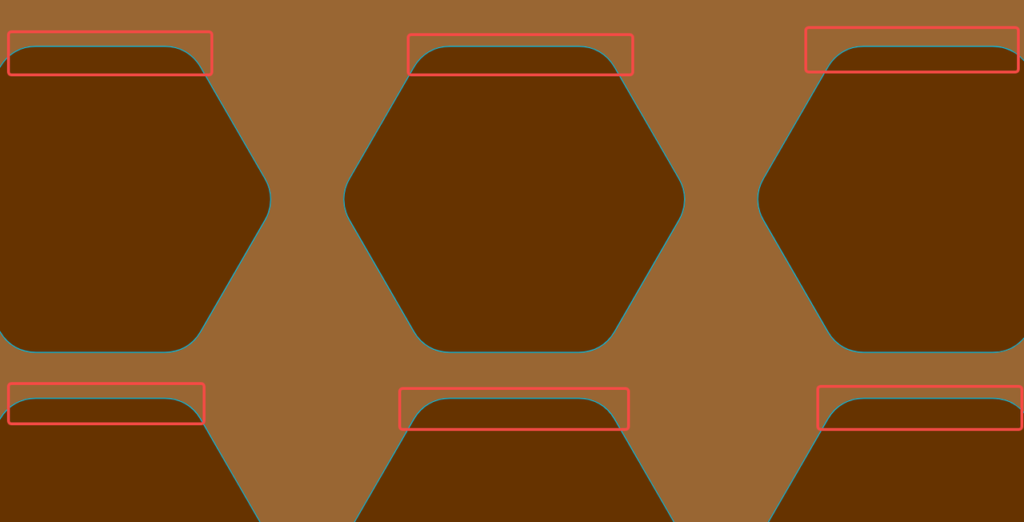

4.If you’re cutting a big area, horizontally align the upper edges of patterns.

e.g. Aligning the upper edges to precisely cut the hexagons out.

Materials

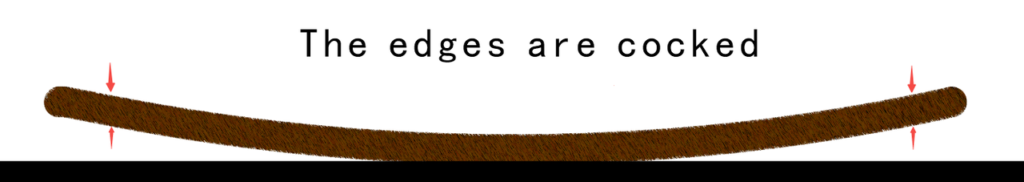

1.Use smooth and flat material. In case of material deformation, try to level it before use.

e.g. Processing the material with cocked edges might cause defocused laser. The processing effect is not as good in that case, and it might accidentally catch fire.

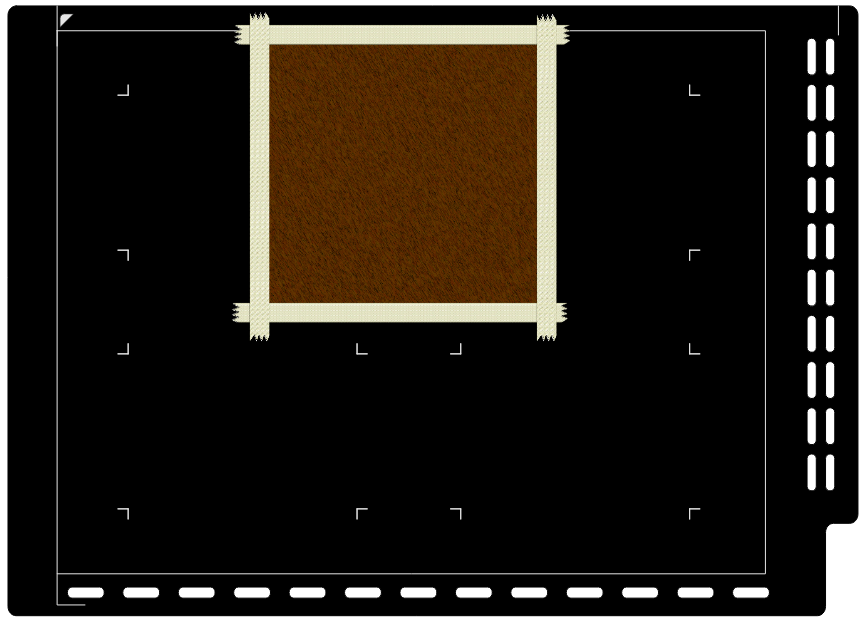

You can fix the deformed material by: using tape to fix the edges around the material to the baseplate to level the material deformation.

2.Use materials with no dent or bulge. If you must use materials with an uneven surface, enter the accurate thickness parameters.

If the material is bent, the image captured by the camera will also be distorted.

In addition, the machine cannot auto-measure the right thickness value of uneven material, thus affecting the processing effect.

Measurement

1.Use a caliper to measure material thickness

There are many factors influencing the precision of M1 auto-measurement, such as the flatness of material, material quality, lighting, environment, etc.

When the machine fails to accurately measure thickness(e.g., when the measurement results are obviously far off), please measure the thickness manually with a caliper.

2.When the baseplate is removed, operate on a flat table and use a focusing ruler to focus.

M1 Manual Focusing Tutorial in Laser Cylindrical Mode

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.