1. Document Overview

This guide applies to xTool MetalFab Series , and is used to illustrate the type selection, purity requirements, pressure and flow rate ranges of shielding gases, as well as standard connection and usage specifications during the laser welding, cutting, cleaning, and engraving processes.

Proper configuration and use of gases are key factors in ensuring welding quality, cutting performance, equipment stability, and safety in use.

2. Why Shielding Gas Is Required for Laser Welding/Cutting

- For laser welding: shielding gas can isolate air to prevent oxidation; stabilize the shape of the molten pool to improve weld consistency; and reduce spatter and welding defects

- For laser cutting: shielding gas can assist in cutting, blow away the molten slag on the cross-section, and improve cutting quality and processing stability.

Therefore, shielding gas is an indispensable component.

3. Why High Purity, Dryness, and Cleanliness of Gas are Required

Gases used for laser welding and cutting act directly on the weld pool or cutting area .

If the gas contains moisture or impurities, it will affect the weld penetration, the quality of the cutting section, and increase the risk of contamination of the nozzle and optical components.

Gas Quality Requirements:

- Do not use mixed gases (such as helium-argon mixture) for laser processing

- When using nitrogen, oxygen, and argon, the gas purity ≥ 99.99%

- When using compressed air, the oil content is less than 0.01 ppm, and the dew point temperature is below 10°C

4. Functions of Different Gases in Laser Processes

4.1 Nitrogen (N₂)

- Noble gases do not participate in chemical reactions

- Effectively prevents metal oxidation

- Cleaner and lighter-colored welds or cut sections can be obtained

Typical Applications:

- Most Welding including Stainless Steel, Aluminum, Not for Titanium.

- Stainless Steel/Aluminum/Brass Cutting

- Laser cleaning with high appearance requirements

4.2 Argon (Ar)

- It is more inert and has better protective effect than nitrogen

- The weld bead is formed stably with a bright appearance

Typical Applications:

- Stainless Steel Welding

- Welding of non-ferrous metals such as aluminum, brass, and titanium alloys

- Laser cleaning with high appearance requirements

4.3 Oxygen (O₂)

- Participates in oxidation reactions and has a combustion-supporting effect

- can significantly improve the cutting ability and speed of carbon steel

Note:

- Will form an oxide layer on the cutting surface

- Not applicable for welding or stainless steel cutting

Typical Applications:

- Carbon Steel Laser Cutting

4.4 Compressed Air (Compressed Air)

- Low cost

- Contains oxygen and nitrogen, and is very suitable for stainless steel cutting

Only recommended for:

- Laser Cleaning

- Cutting of stainless steel, brass, aluminum, and carbon steel and galvanized sheets less than 1mm (the cross-section will turn black)

5. Official Gas Requirements for xTool MetalFab

Instructions:

- The following are the gas requirements stably provided during the processing. If using the Savegas Nozzle, only a pressure above 0.6 MPa is required, which refers to stably providing a pressure above 0.6 MPa, different from the nominal maximum pressure. If using the xTool air compressor, the target pressure needs to be set to 1.0 MPa

- If using your own air compressor and refrigerated dryer system, the specific requirements for CNC cutting are:

When using an ordinary nozzle, it should be higher than 150L/min @1.2MPa; when using the SaveGas Nozzle, it should be higher than 200L/min @0.6 MPa

Processing Type | Material Type | Recommended Gas | Recommended Pressure | Recommended Nozzle |

CNC Cutting | Stainless Steel | 99.99% Nitrogen or | Over 87 PSI (0.6 MPa) | Ordinary cutting nozzle |

Stainless Steel (2mm-5mm) | Over 174 PSI (1.2 MPa) | Ordinary cutting nozzle | ||

Over 87 PSI (0.6 MPa) | SaveGas™ Nozzle | |||

Titanium Alloy TC4 (1mm) | 99.99% Argon | Over 174 PSI (1.2 MPa) | Ordinary cutting nozzle | |

Titanium Alloy TC4 (2mm-5mm) | SaveGas™ Nozzle | |||

Carbon Steel (2mm-10mm) | 99.99% Oxygen | 7.25 PSI-10.15PSI (0.05-0.07MPa) | Double-layer Nozzle & focus extension tube | |

CNC Engraving | Stainless Steel | Compressed Air or 99.99% Nitrogen or | 43.5 PSI-58 PSI (0.3 MPa-0.4 MPa) pressure | Ordinary Nozzle |

CNC Rust Removal | Stainless Steel | 99.99% Nitrogen or | 87 PSI-116 PSI | CNC Cleaning Nozzle |

Handheld Rust Removal with MaxClean™ | 43.5 PSI-87 PSI (0.3 MPa-0.6 MPa) pressure | MaxClean™ Accessory (add-on) | ||

Handheld Cutting | Over 116 PSI (0.8 MPa) pressure | Handheld Cutting Tip | ||

Handheld Welding | 99.99% Nitrogen or | 15-30L/min flow rate or 14.5 PSI-29 PSI (0.1 MPa-0.2 MPa) pressure | Welding Nozzles | |

Post-weld Cleaning | Cleaning Nozzle |

6. Estimation of Gas Consumption for xTool MetalFab

6.1 Estimation of gas consumption for welding:

With a 40L full bottle, pressurized to 15MPa, and a gas flow rate of 15 - 30 lpm, one bottle can sustain welding for approximately 200 - 400 min (3 - 6 h)

6.2 Estimated gas consumption for CNC cutting:

xTool experimental test data:

A full 40L bottle of nitrogen with a pressure of 15MPa and a purity of 99.99%, using a 2.0mm ordinary nozzle, can continuously emit gas for approximately 40 minutes at a gas pressure of 0.8MPa, with a gas flow rate of approximately 150 lpm; at a gas pressure of 1.4MPa, it can continuously emit gas for approximately 33 minutes, with a gas flow rate of approximately 180 lpm.

According to the cutting requirements:

With 2.0mm ordinary nozzle, at 1.2MPa air pressure, a 40L full bottle of nitrogen can theoretically last about 35 minutes; With 4.0 nozzle, at 0.6MPa, a 40L full bottle of nitrogen can theoretically last about 13 minutes.

With 1.0mm double-layer nozzle, at 0.06MPa air pressure, a full 40L oxygen bottle can theoretically last about 14 hours.

*The data is based on theoretical calculations, for reference only, and will actually be affected by factors such as airtightness, gas cylinder capacity, nozzle diameter, etc.

So CNC cutting consumes a significant amount of gas (especially nitrogen or argon). Therefore, when cutting materials such as stainless steel, aluminum, or brass, we recommend using compressed air, which offers better cost-effectiveness; use oxygen only when cutting thick carbon steel; and use nitrogen or argon only during welding.

7. Gas Connection Guidelines

7.1 Gas Requirements

- High-pressure gas cylinders (nitrogen / argon / oxygen, purity at least 99.99%) or compressed air (must have a cold drying system, oil content less than 0.01 ppm, dew point temperature below 10°C)

7.2 Common Accessories

- Pressure Relief and Regulation:

- Dual-Gauge Pressure Reducing Valve (Pressure Display + Byte Flow Control, essential for CNC cutting with gas cylinders, range up to 1.6 MPa)

- Pressure regulating valve (capable of real-time pressure control + convenient for quick deflation and gas source replacement, optional, not must)

- Flow valve (controls flow, preferred for welding, can also be replaced by a pressure reducing valve)

- Electrical proportional valve (Oxygen cutting control pressure plan A, requires a 24V power adapter; the front-end gas cylinder needs to be connected to a flow valve or pressure reducing valve)

- Precision pressure-regulating pressure reducing valve (Oxygen cutting control pressure plan B, can be directly connected to gas cylinder)

Dual-Gauge Pressure Reducing Valve | Flow valve/ flow meter | Electrical proportional valve, e.g.: SMC ITV2050-312BL | Pressure regulating valve/ pressure regulator | Precision pressure-regulator, e.g.: PneumaticPlus PPR2-N02BG-2 |

- Gas Line and Adapter:

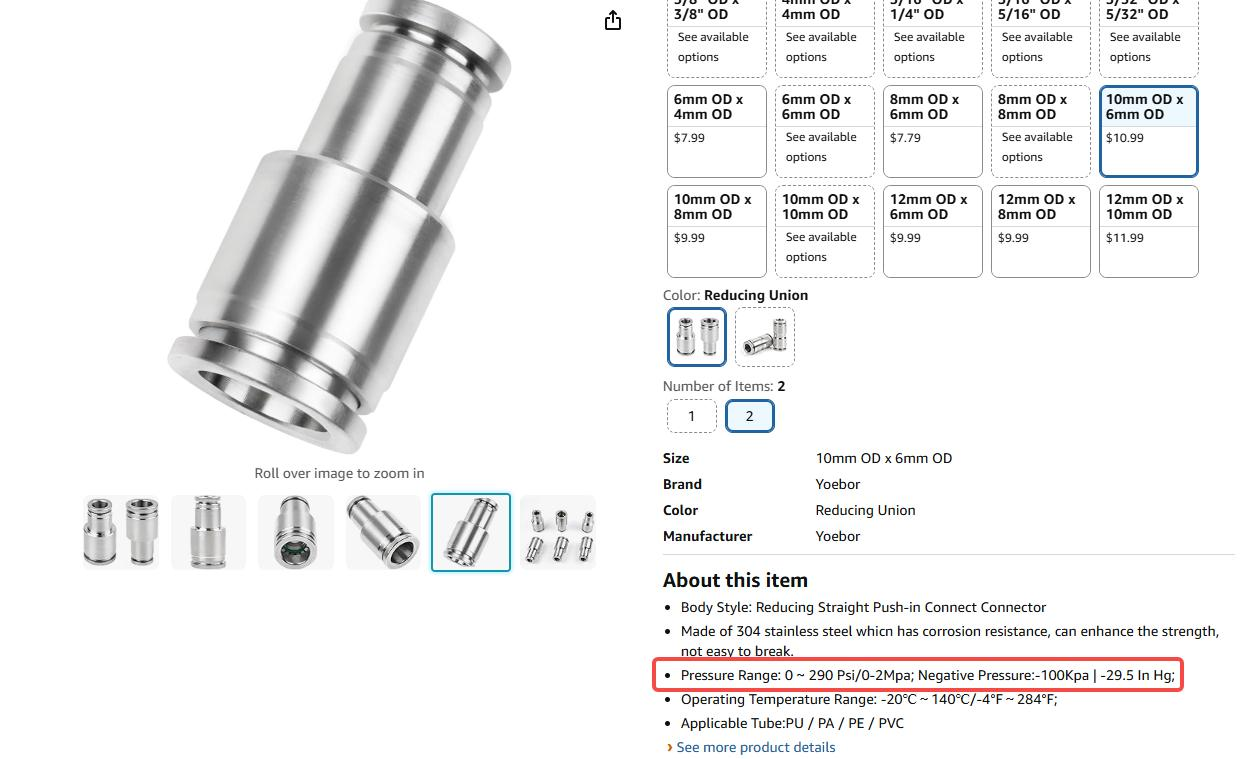

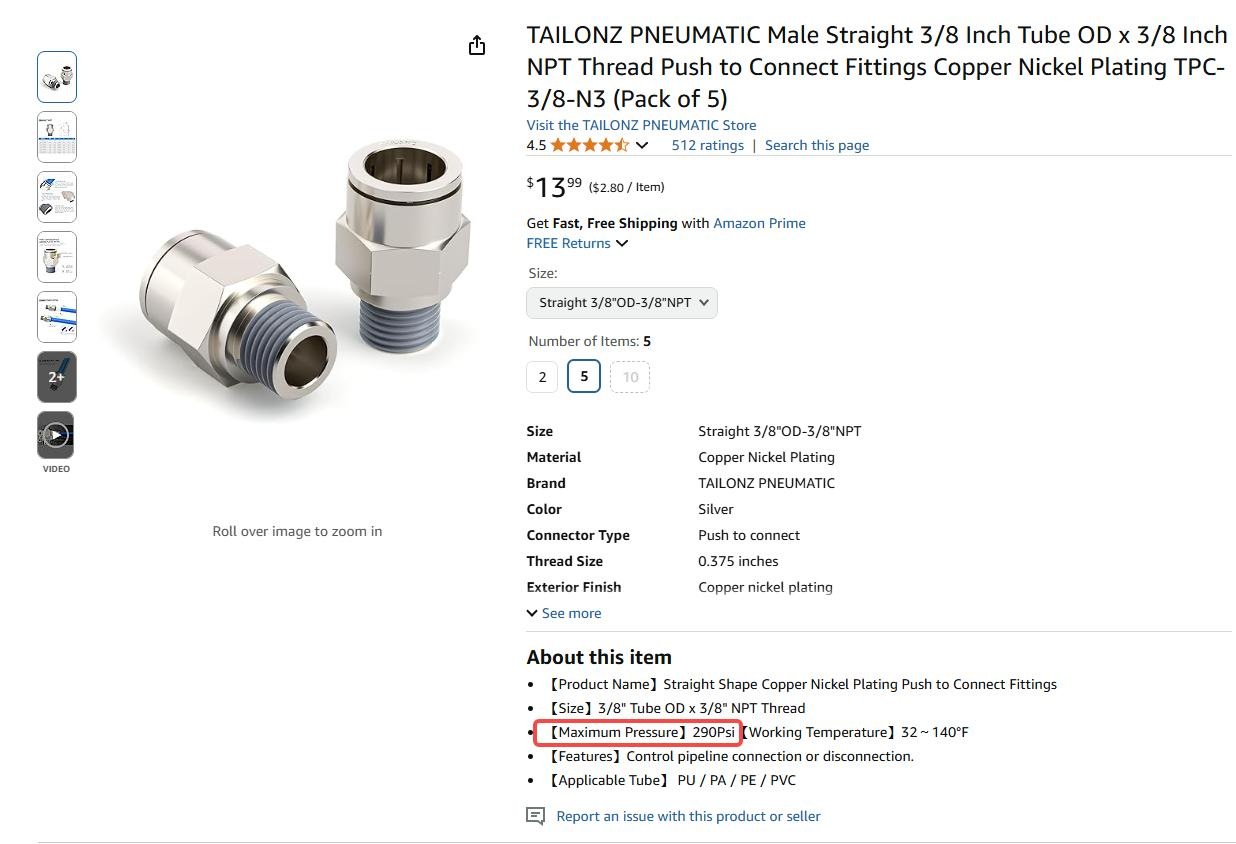

The outer diameter of the air intake hole of the xTool welding machine is approximately 10mm. Taking a US 1/4 standard gas cylinder as an example, an adapter is required.

- Pressure-resistant gas hose (rated pressure ≥ actual working pressure, xTool comes standard with a 10mm, 5m long gas hose)

- Push-to-connect gas hose adapter (Connection sequence: 1/4" standard gas cylinder - 1/4" gas hose - gas hose adapter - 10mm gas hose)

- Gas cylinder adapter (Connection sequence: 1/4" standard gas cylinder - gas cylinder adapter - 10mm gas hose)

- Auxiliary Tools

- Raw tape (used at various adapter joints, air compressors, and gas cylinder interfaces to prevent gas leakage)

- Adjustable wrench (for disassembling and replacing gas cylinders)

- Gas Cylinder Fixing Device (Trolley)

7.3 Connection Order

- Nitrogen/Argon/Air Gas Cylinder: Taking a 1/4 Standard Gas Cylinder as an Example

- Plan A: Gas Cylinder Adapter: Gas Cylinder - 1/4" Pressure Regulator/Flow Valve - 1/4"-to-3/8" Gas Cylinder Adapter - Pressure Regulator (Optional, Not Mandatory) - 10mm Gas Hose - MetalFab Laser Welder

- Plan B: Gas Hose Adapter: Gas Cylinder - 1/4'' Pressure Regulator/Flow Valve - 1/4'' Gas Hose - 1/4''-to-3/8'' Gas Hose Adapter - Pressure Regulator (Optional) - 10mm Gas Hose - MetalFab Laser Welder

- Oxygen Cylinder: Taking a 1/4 standard cylinder as an example

- Plan A: Proportional Valve + Pressure Reducing/Flow Valve : Gas Cylinder - 1/4 "'Aperture Pressure Regulating Valve/Flow Valve (not adjustable to 0.05-0 06MPa) - 1/4"' Gas Hose - 1/4 "'-to-3/8"' Gas Hose Adapter - 10mm Gas Hose - Proportional Valve - 10mm Gas Hose - MetalFab Laser Welder

- Plan B: Pressure Reducing Valve Only : Gas Cylinder - 1/4"Pressure Reducing Valve (can be directly adjusted to 0.05-0 06MPa) - 1/4"' Gas Hose - 1/4 "'-to-3/8"' Gas Hose Adapter - 10mm Gas Hose - MetalFab Laser Welder(gas cylinder adapter plan is also available)

- Air Compressor:

Air Compressor - Pressure Regulating Valve (Optional, Not Required) - 10mm Gas Hose - MetalFab Laser Welder

8. Safety Notes

- DON'T operate any laser process without shielding gas.

- DON'T use any gas containing oil, water, or of unknown origin.

- DON'T use oxygen for welding or stainless steel cutting.

- Regularly check the airtightness of the hose and joints.

- Secure the gas cylinder in a safe area that is not easily accessible to collisions.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.