Preparations

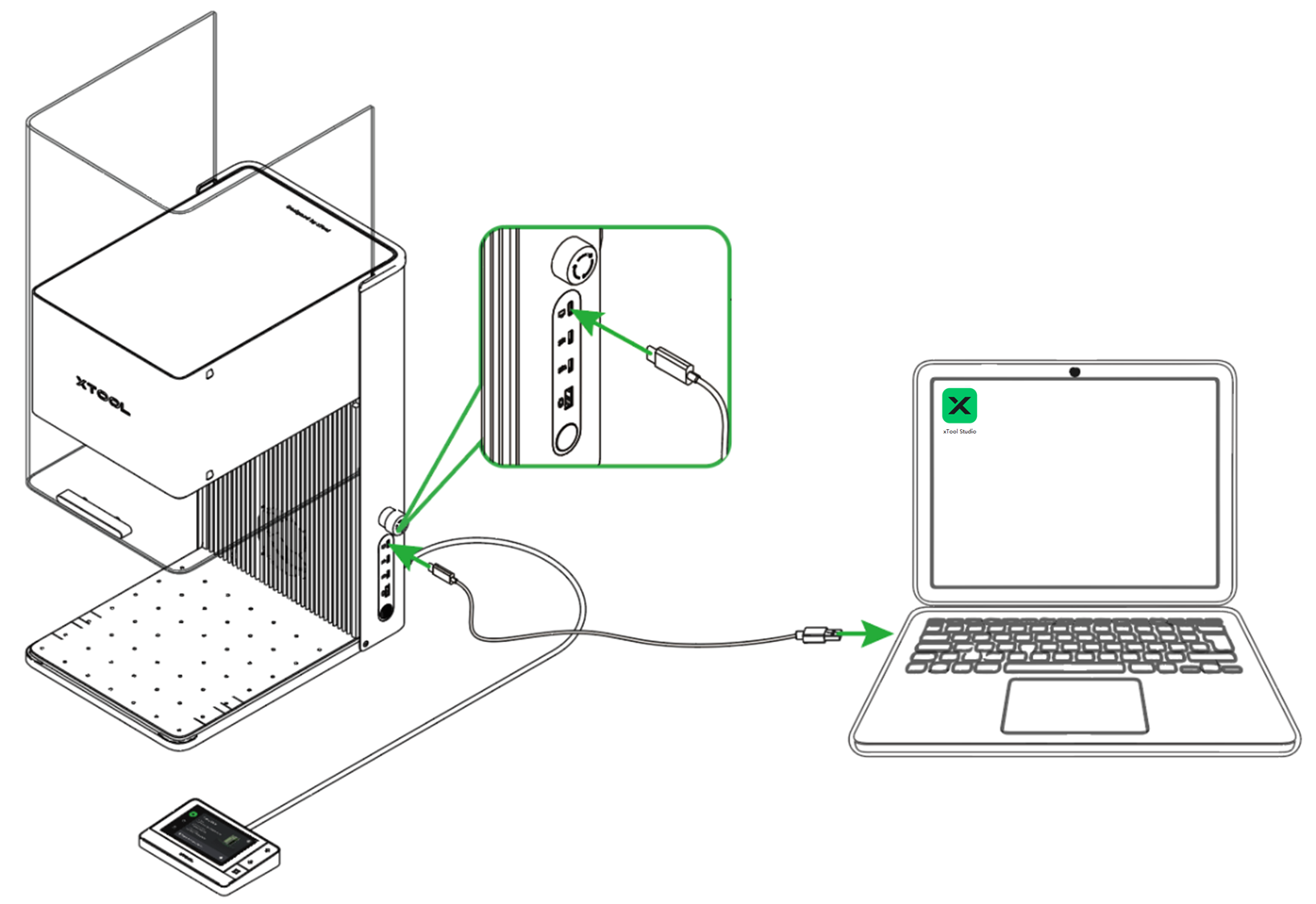

1. Connect the conveyor to xTool F1 Ultra

Follow the instructions in Install the conveyor on F1 Ultra to install and connect the conveyor.

2. Connect xTool F1 Ultra to xTool Studio

(1) Use the USB cable to connect xTool F1 Ultra to your computer.

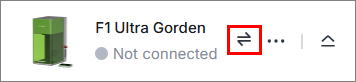

(2) Open xTool Studio. In the top-right corner, click + New project.

(3) On the right side of the project editing page, click + Select device.

.png) icon next to the device.

icon next to the device.

(4) On the pop-up window, click Connect Device. Then, click the name of your device.

Process multiple materials in batches

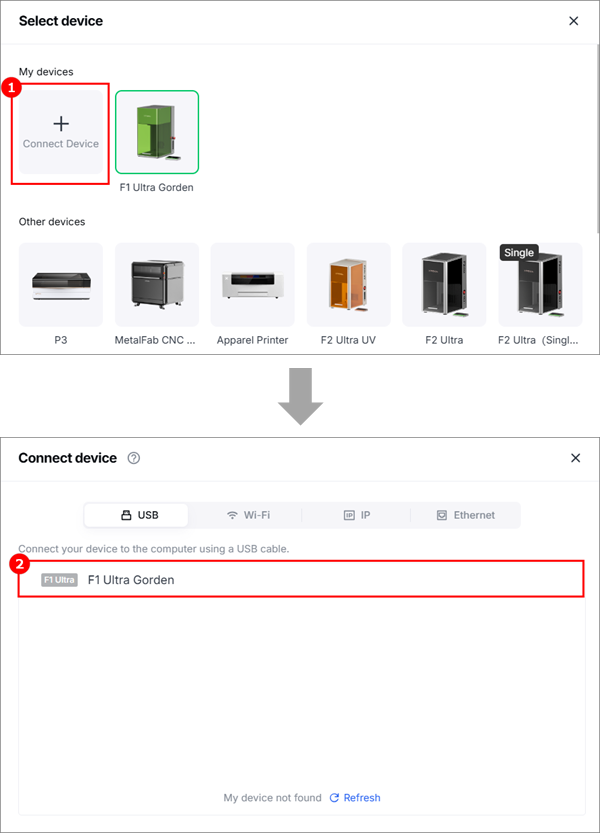

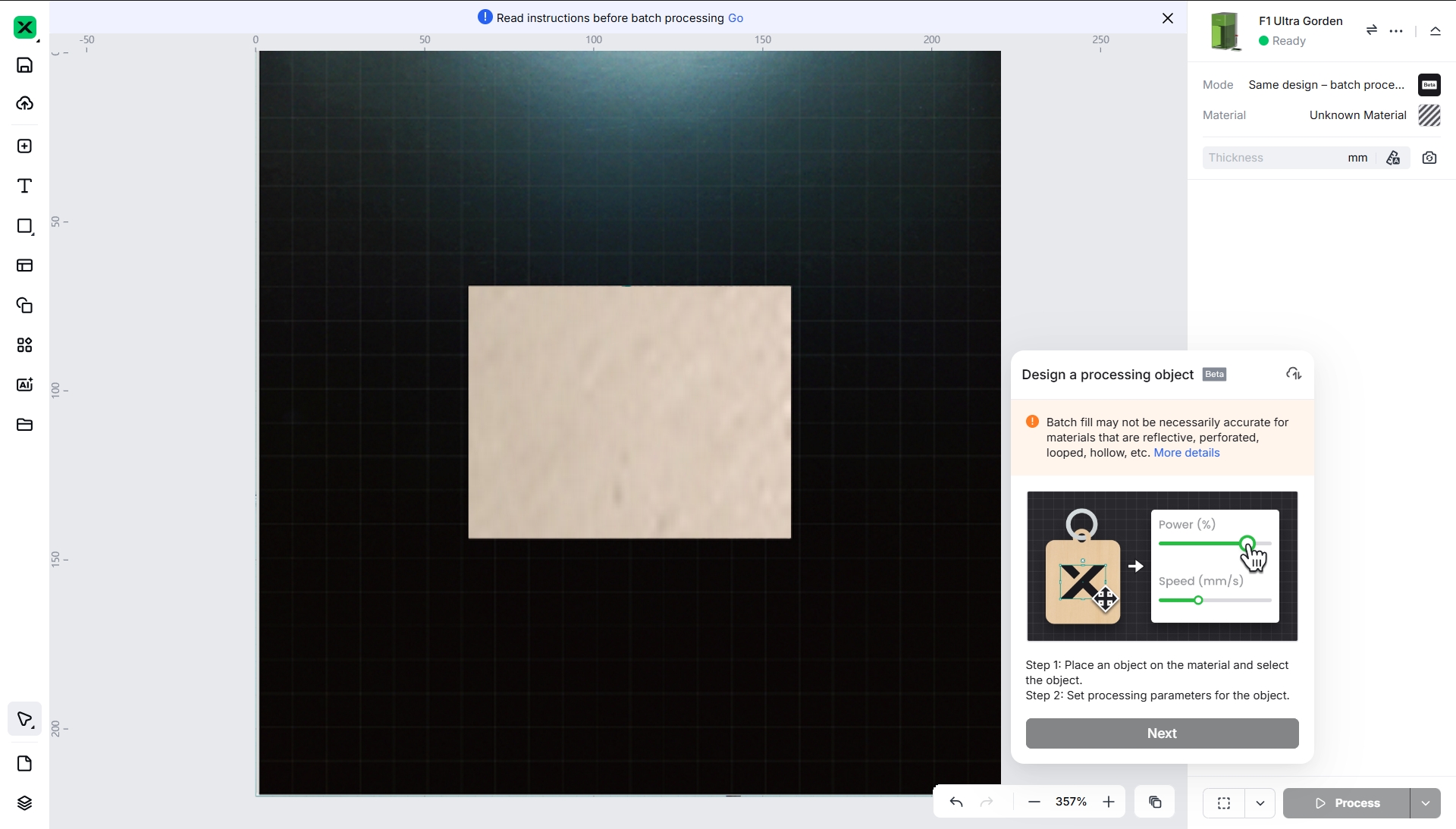

1. Select the processing mode

(1) On the right side of xTool Studio, click the name of the current processing mode, then select Same design - batch processing as the processing mode.

(2) Click Unknown Material, select the desired material, and click Apply.

The recommended parameter settings can achieve the best results only when using xTool's materials. If you are using materials from third parties, it is recommended that you conduct a material test array on your own first to obtain the desired effects and parameters. Meanwhile, ensure that the materials are free from moisture or contamination, which may greatly affect the results.

2. Place the material and perform laser focusing

(1) Lift the protective enclosure, and place the material on the flat surface, allowing the blue light spot to fall on the surface.

(2) Hold down on the Up/Down button to lift or lower the laser module. When the red and blue light spots overlap, the focus is successfully set.

3. Shoot background and design a processing object

(1) In the top-right corner of xTool Studio, click the Refresh background  icon.

icon.

xTool Studio takes a photo of xTool F1 Ultra’s processing area and inserts the photo as the canvas background. You can position processing objects based on the background.

- To ensure positioning accuracy, set the laser focus before shooting background.

- Ensure that the background photo can fully and clearly display the material. You can adjust the shooting environment by adjusting the device's fill light or pulling down the protective enclosure.

- If the materials in the photo have obvious shadows or are not clear, adjust the material position and click Refresh again to take a new photo.

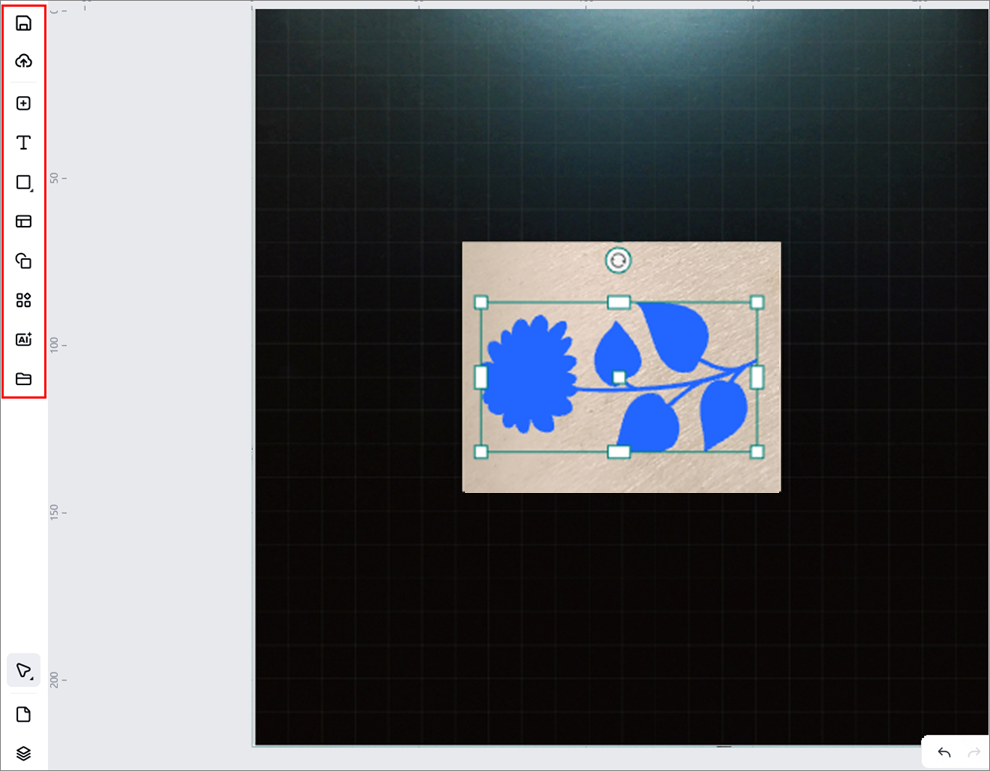

(2) Using the tools to the left of the canvas, create an object inside the material.

(3) Select the object to further edit it using the tools on the top of the canvas.

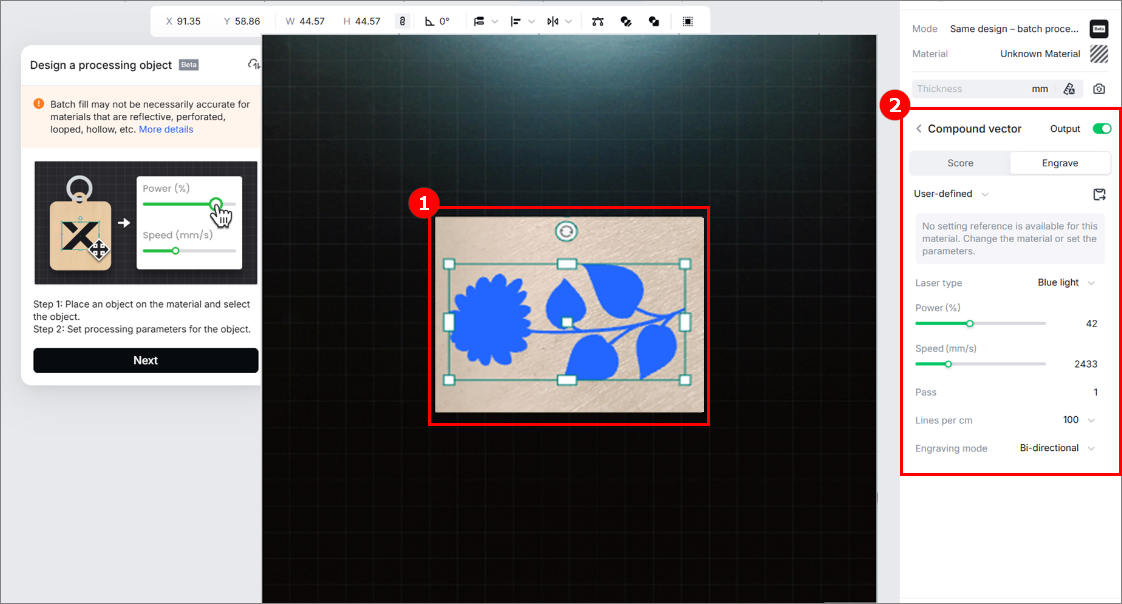

4. Set the processing parameters and processing path

(1) Select objects on the canvas. On the right side of xTool Studio, set parameters for the selected objects.

(2) In the bottom-right corner, click the  icon to set the processing path.

icon to set the processing path.

Evade smoke: When this feature is enabled, the device follows a path less affected by the smoke to process the material.

Processing path:

- Auto planning: xTool Studio automatically plans the processing path based on intelligent algorithms.

- User defining: Manually set the processing paths for some objects.

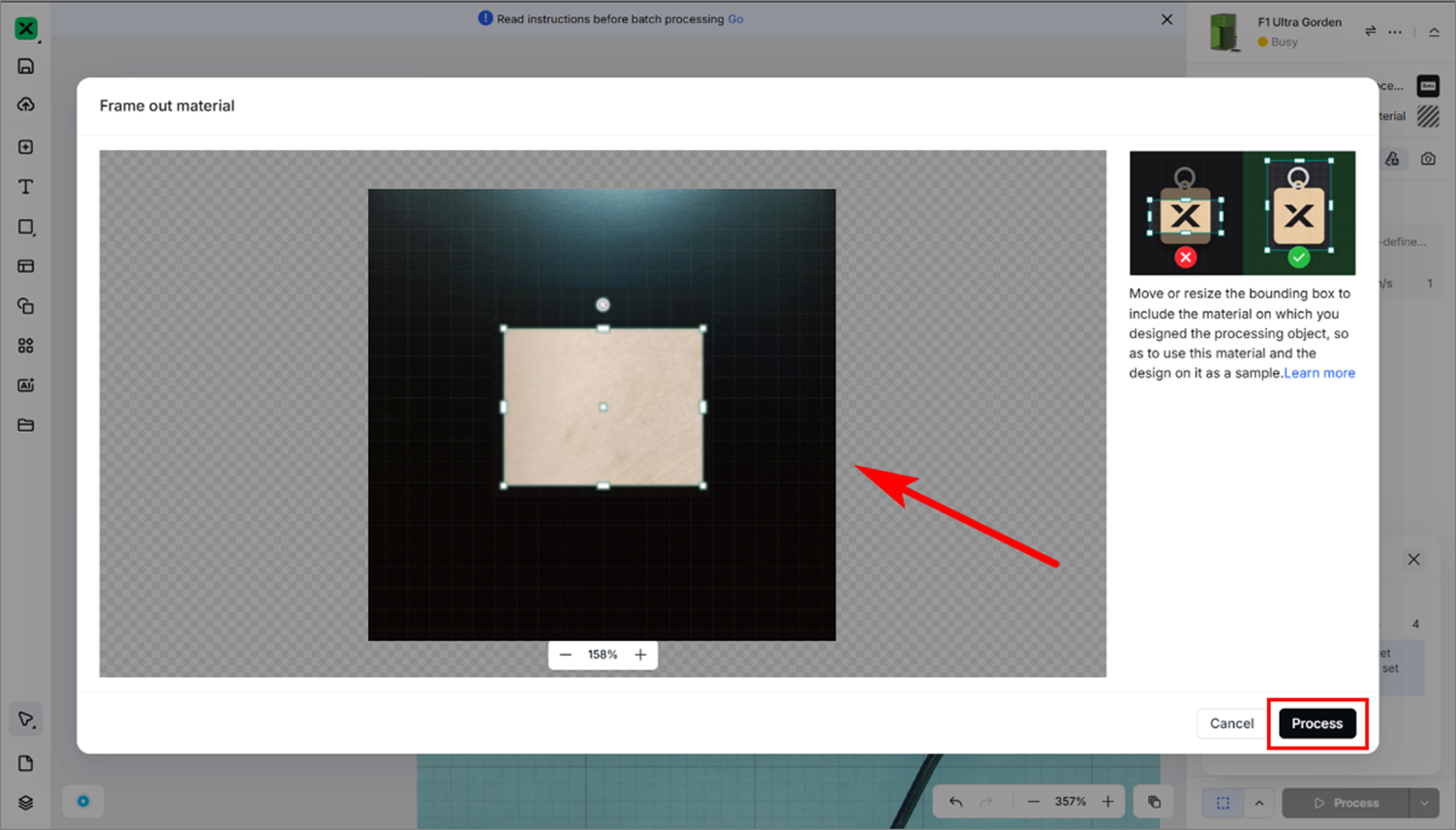

5. Frame out the sample material

The first material placed in the processing area is used as the sample material. During batch processing, xTool Studio will fill the other materials based on the sample design. Framing out the sample material helps improve the accuracy of batch filling.

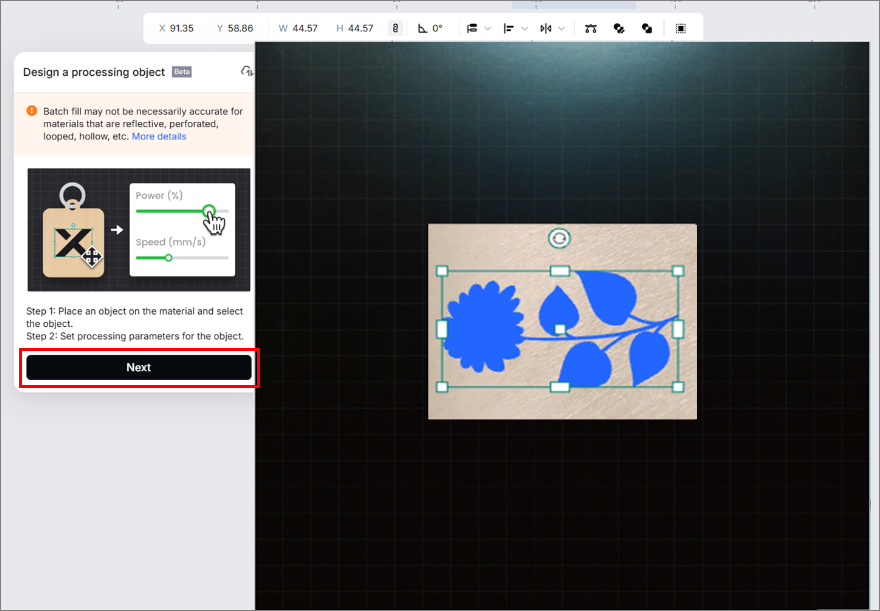

(1) After setting parameters, click Next.

(2) In the pop-up window, move or resize the bounding box to include the sample material inside it. Then, click Process.

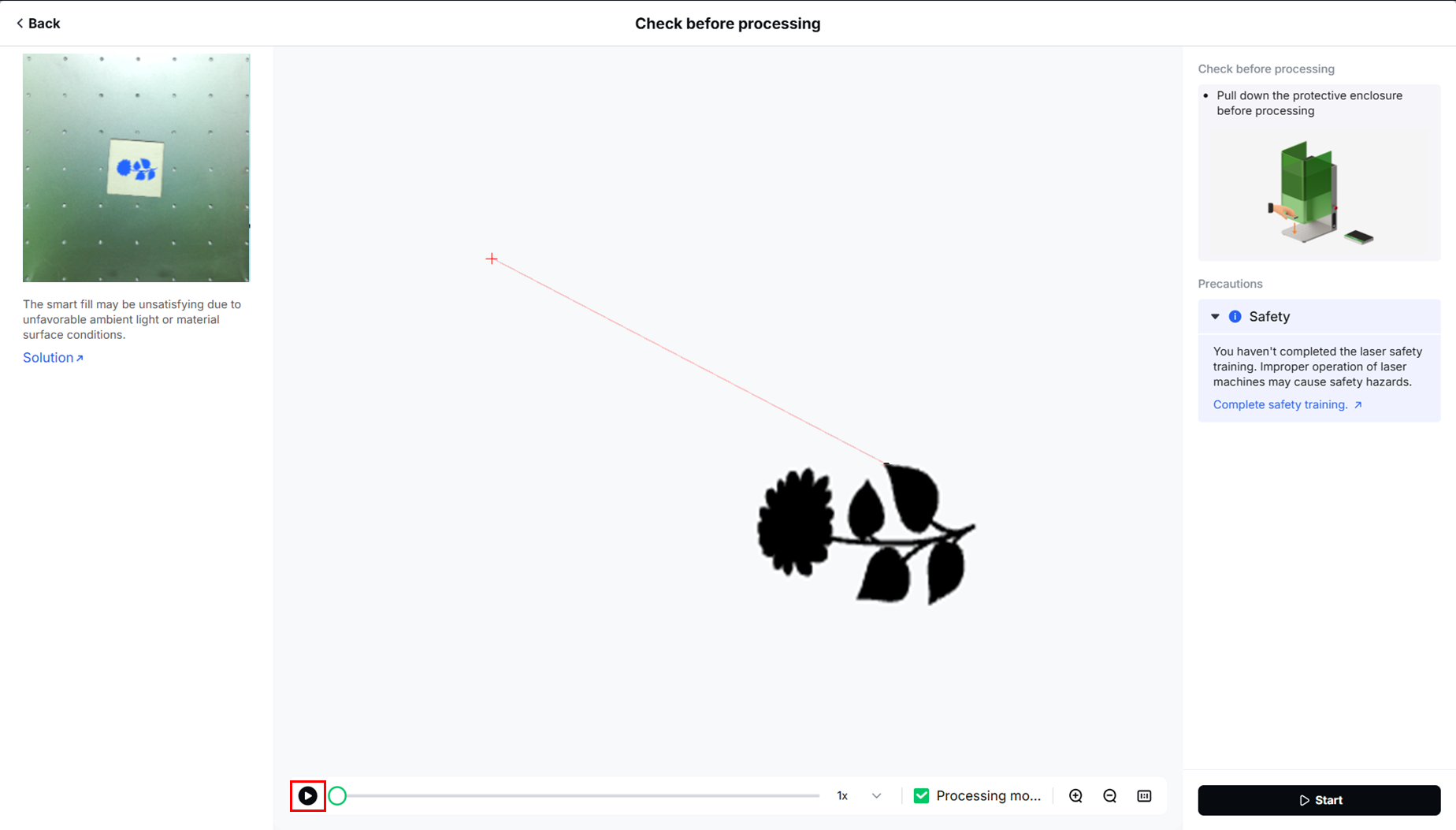

6. Preview the processing area

You can preview the processing area on the material by framing. Framing means laser dots walk along the border of the processing objects on the material. Take the following steps to start framing:

(1) At the bottom-right corner of the software, click the  icon next to the Framing button to set the parameters for framing.

icon next to the Framing button to set the parameters for framing.

● Light power: Sets the laser power for framing.

● Mode: In the Rect mode, laser dots walk along the rectangle border of the processing objects. In the Outline mode, laser dots walk along the outline of the processing objects.

(2) Click![]() . The laser dots will move along the boundary of the processing objects on the material so that you can preview the processing area.

. The laser dots will move along the boundary of the processing objects on the material so that you can preview the processing area.

To stop framing, click the same button.

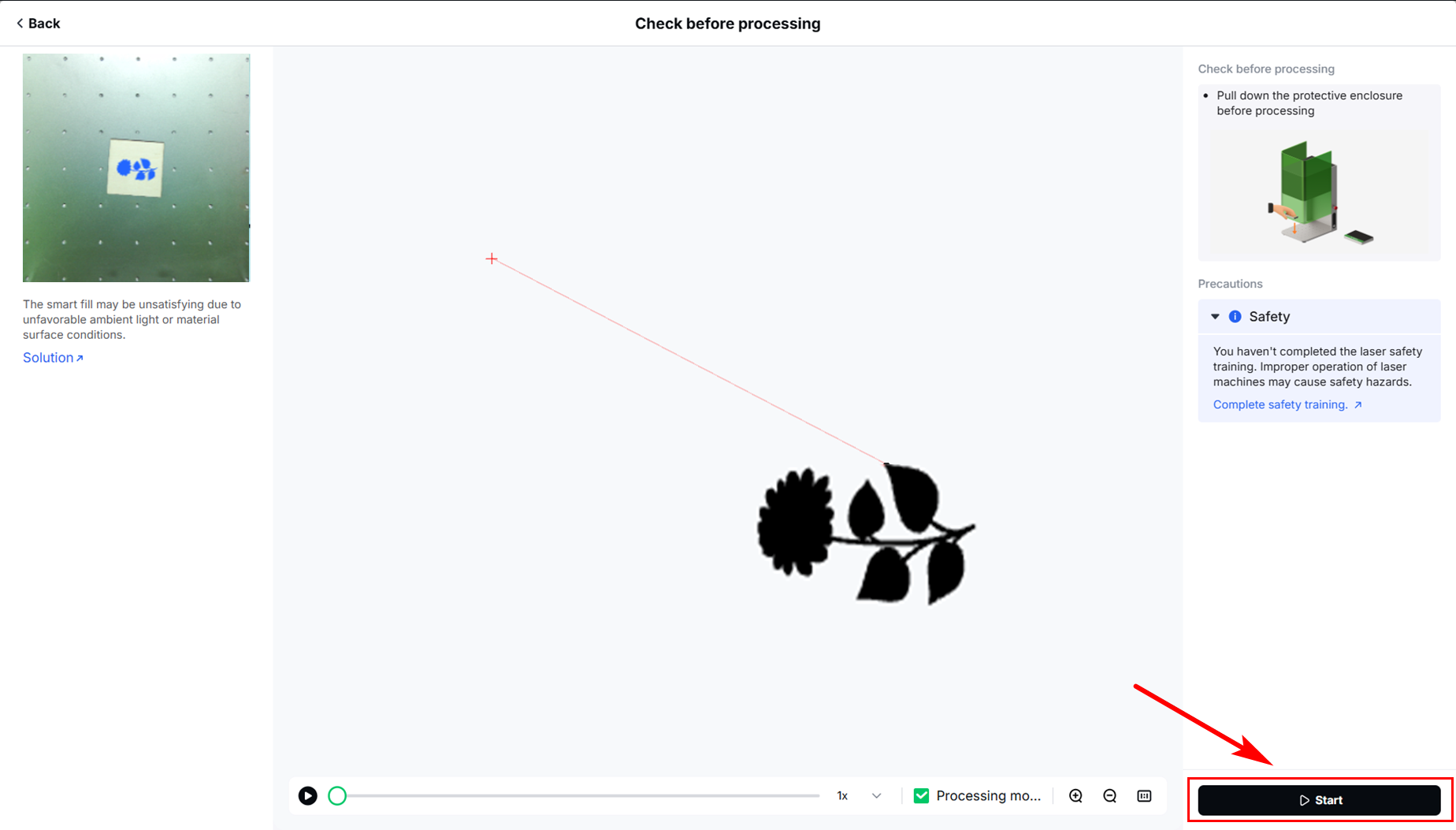

7. Start processing

(1) In the bottom-right corner of the software, click Process.

(2) Preview the processing pattern and path.

In the bottom-left corner, click thebutton, and xTool Studio will show you the processing path.

(3) Wear a pair of goggles that can shield laser beams of 455 nm and 1064 nm wavelengths.

- When xTool F1 Ultra is used with the conveyor, its protective enclosure cannot be fully closed. For your safety, it is recommended that you wear goggles during processing.

- Safety goggles are not included with xTool F1 Ultra or the conveyor. Please purchase them separately.

(4) Close the protective enclosure. In the bottom right corner, click Start. When the software shows Ready, press the XTOOL Start/Stop button on the touchscreen controller to start processing.

(5)During processing, keep adding new materials to the conveyor. Place them to the right of the processing area.

- When placing materials, keep your hands away from the processing area to avoid injuries.

- Do not place a material close to the edges. Otherwise, the material may fail to be processed.

- Ensure that the materials do not touch or overlap with each other.

8. Stop processing

Auto-stop: If no material is detected for 5 consecutive times, the batch processing will be automatically ended.

Manual-stop: Click Cancel in xTool Studio or double press the XTOOL Start/Stop button on the touchscreen controller.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.