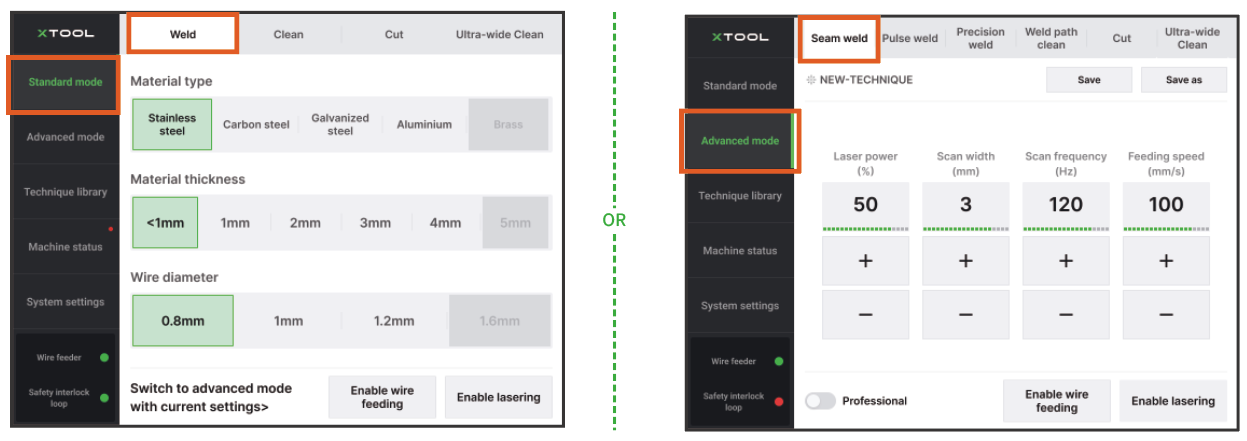

Weld / Seam weld

Descriptions

The welding head emits continuous laser beams to melt and join the materials along a seam. This process ensures strong, uniform bonds, making it a reliable method for various welding needs.

Applications

Seam welding is primarily used for general-purpose welding tasks. Its versatility and efficiency make it suitable for a wide range of applications.

How to start

In Standard mode, tap Weld for straightforward operations.

Alternatively, in Advanced mode, select Seam Weld to access enhanced customization options to meet your specific welding requirements.

Note: For more information, see Start Wire-Filled Welding. |

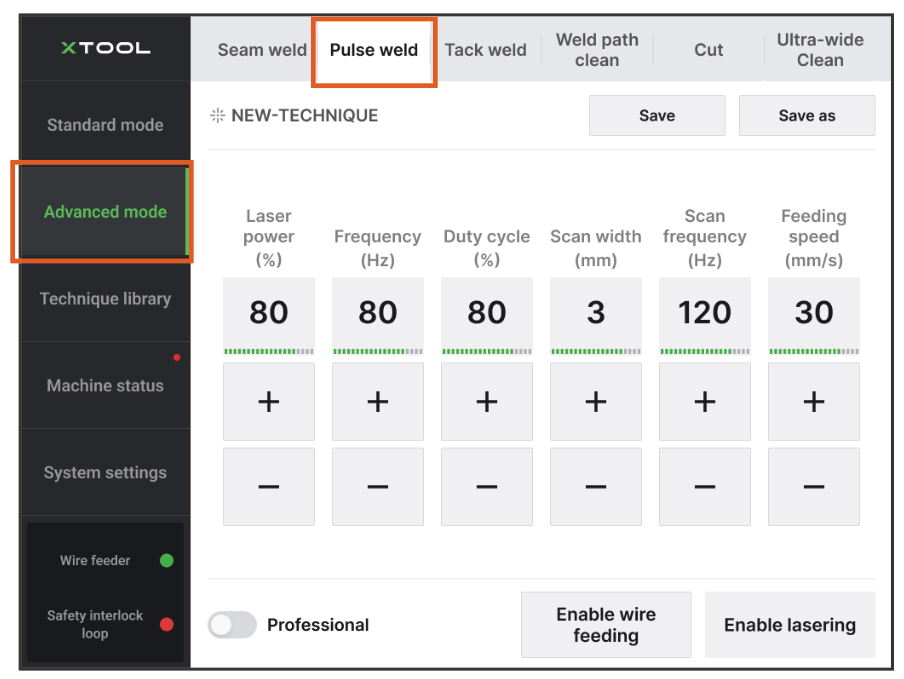

Pulse weld

Descriptions

The welding head emits pulsed laser beams to weld the workpiece. It keeps the overall heat input of a weld low while still getting proper penetration.

Applications

- Welding thin metal sheets

- Creating attractive welding beads, like a fish scale pattern.

How to start

In Advanced mode, select Pulse Weld.

Note: For more information, see Tack Welding and Pulse Welding. |

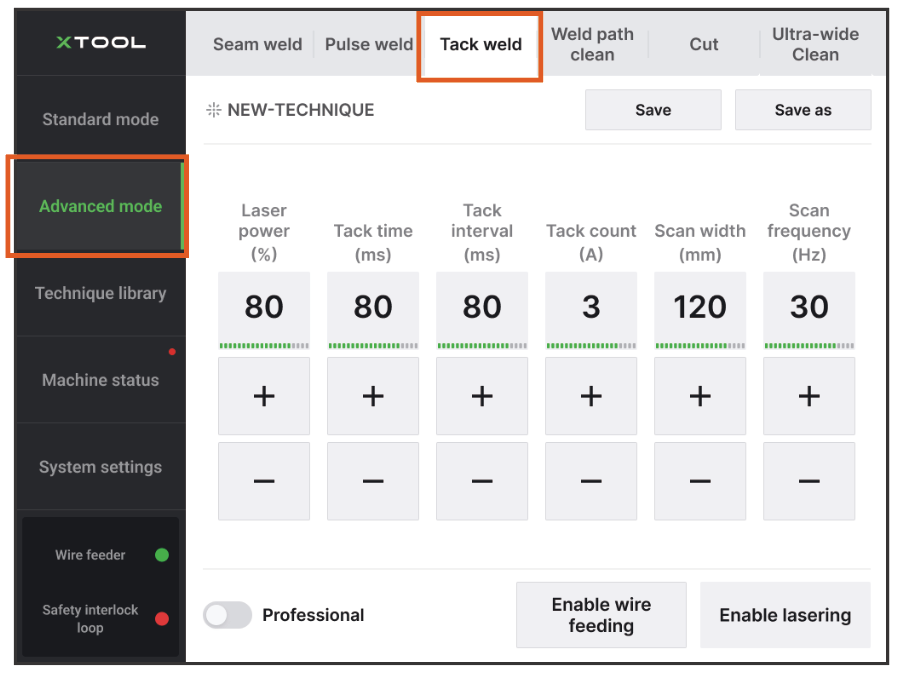

Tack weld

Descriptions

The welding head welds at a point using brief bursts of laser emission, creating small, dot-like welds.

Applications

- Pre-welding to align and temporarily secure parts, ideal for thin metal sheets

- Connecting small or tiny parts with precision

How to start

In Advanced mode, select Tack Weld.

Note: For more information, see Tack Welding and Pulse Welding. |

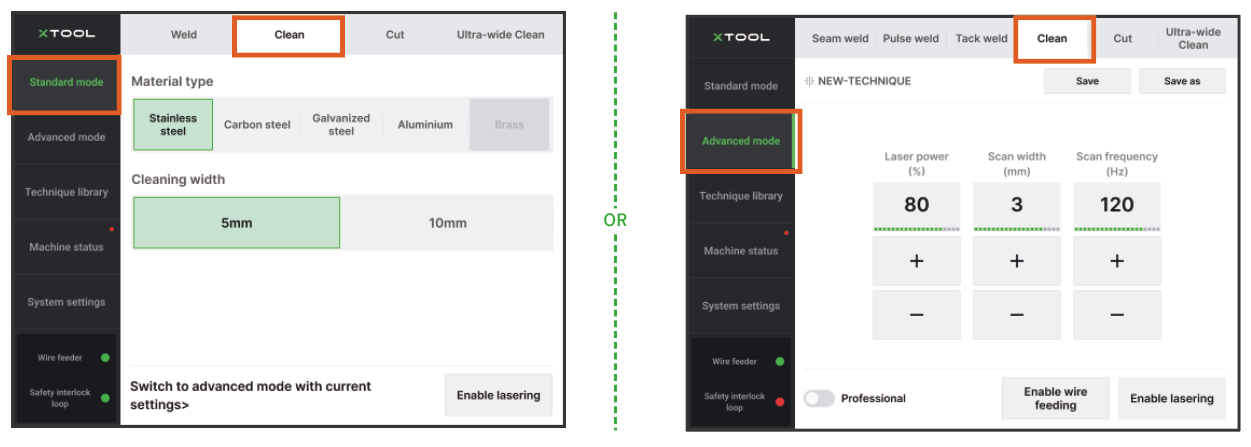

Clean

Descriptions

The welding head emits laser beams to scan a specific width of area on the material surface, vaporizing and ablating the contaminants.

Applications

- Removing oxides from the weld path

How to start

In Standard mode, tap Clean for straightforward operations.

Alternatively, in Advanced mode, select Clean to access enhanced customization options to meet your specific requirements.

Note: For more information, see Start Metal Cleaning (Handheld Cleaning). |

Cut

Descriptions

The welding head emits focused laser beams to slice through materials. It utilizes intense heat to melt, burn, or vaporize the material along the cutting path.

Applications

- Cutting thin metal sheets

How to start

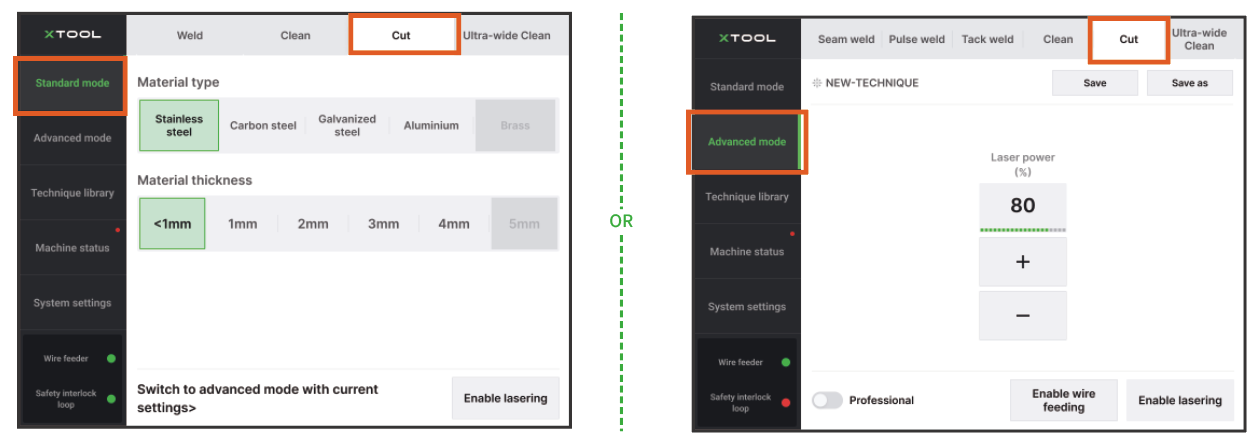

In Standard mode, tap Cut for straightforward operations.

Alternatively, in Advanced mode, select Cut to access enhanced customization options to meet your specific requirements.

Note: For more information, see Start Metal Cutting (Handheld Cutting). |

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.