Start Metal Cleaning with xTool MetalFab CNC Cutter

Updated Aug 14,2025

Updated Aug 14,2025

Brief introduction

With the cleaning nozzle installed, xTool MetalFab CNC Cutter supports automatic rust and paint removal for multiple metals including steel plates and molds. The smart function helps to avoid uneven cleaning caused by manual operation.

Cleaning nozzle for CNC use

Procedures

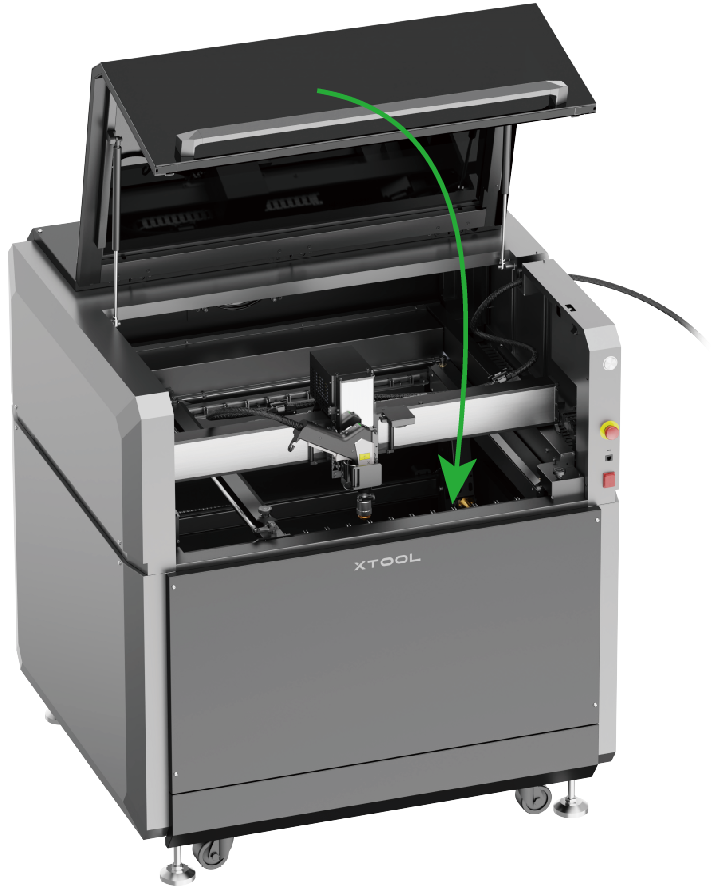

Step 1: Install the cleaning nozzle

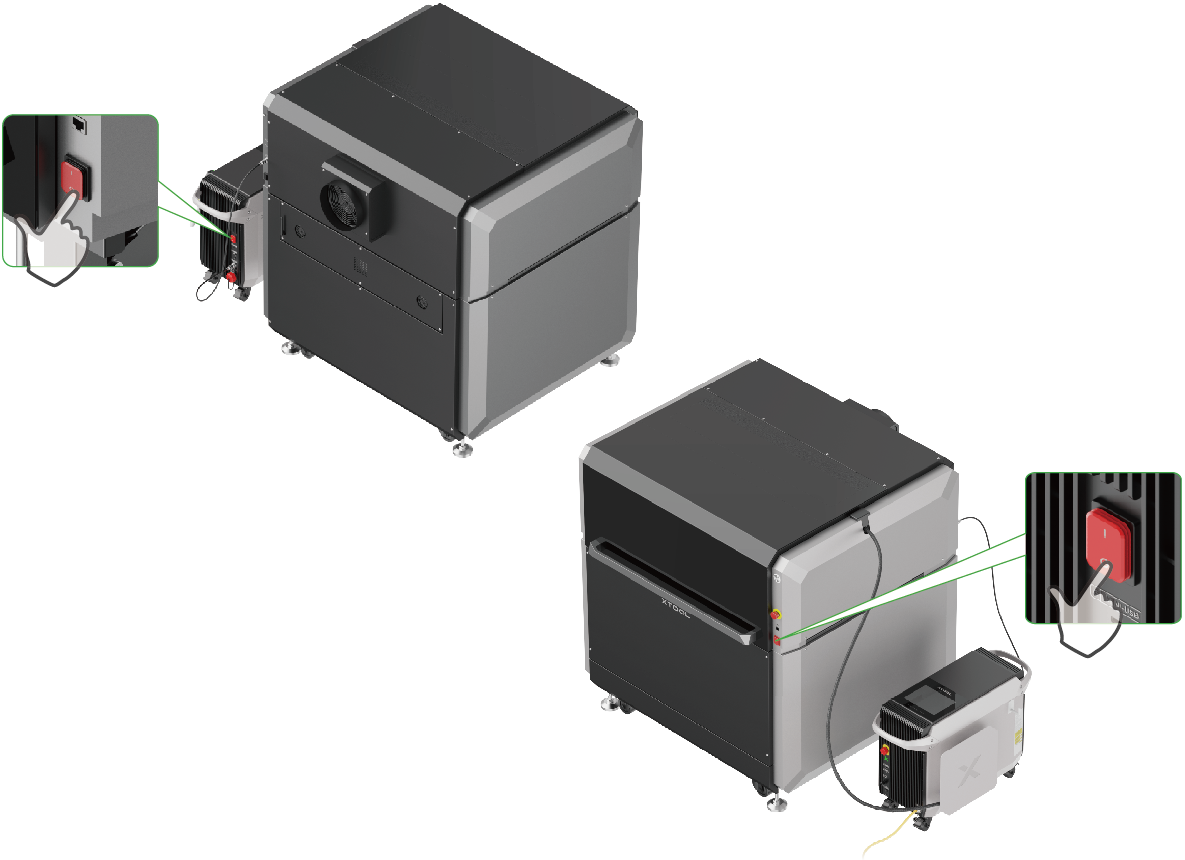

- Turn off the two machines.

- Open the protective lid of xTool MetalFab CNC Cutter and take out the welding head from the carriage.

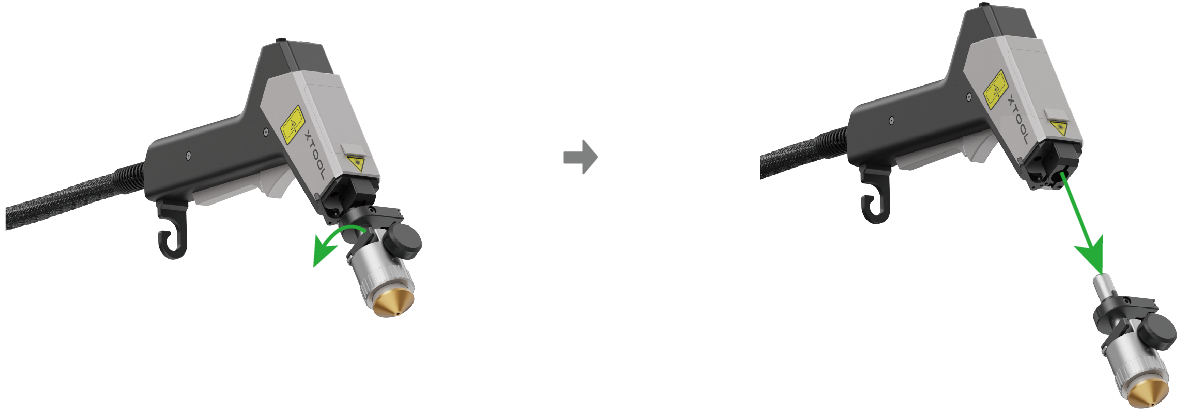

- Take off the cutting tip.

- Install the cleaning nozzle.

- Reinstall the welding head.

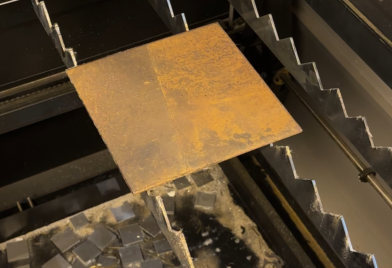

Step 2: Place the material

- Place the material on the slats.

Note: If the material is thin, use the fixtures to fix it.

- Close the protective lid.

- Turn on the two machines.

Step 3: Configure settings in XCS

- Connect your xTool MetalFab CNC Cutter in XCS and recalibrate the machine.

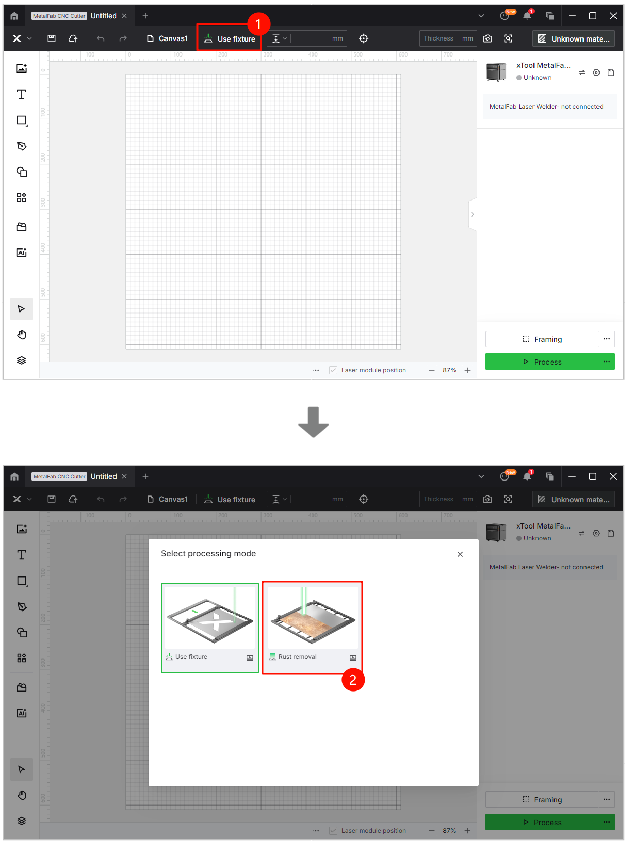

For more details about the calibration process, watch the corresponding part in the unboxing video tutorial. - Set the processing mode as Rust removal.

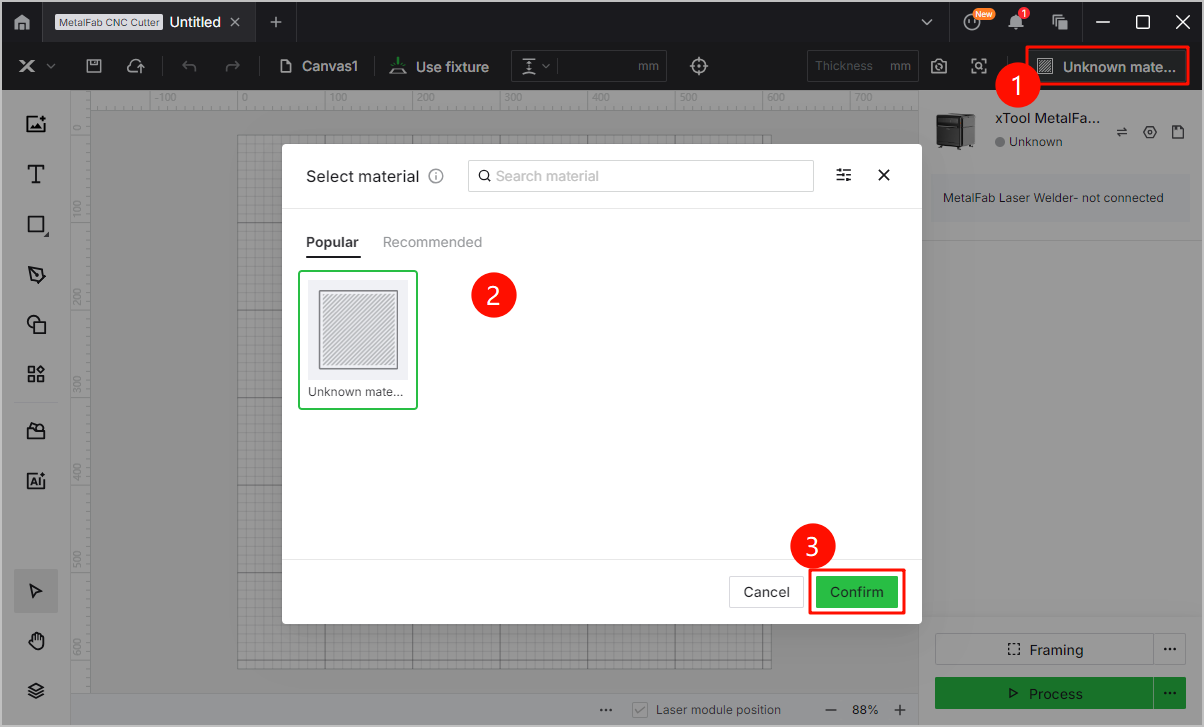

- Click Unknown material and select your target material.

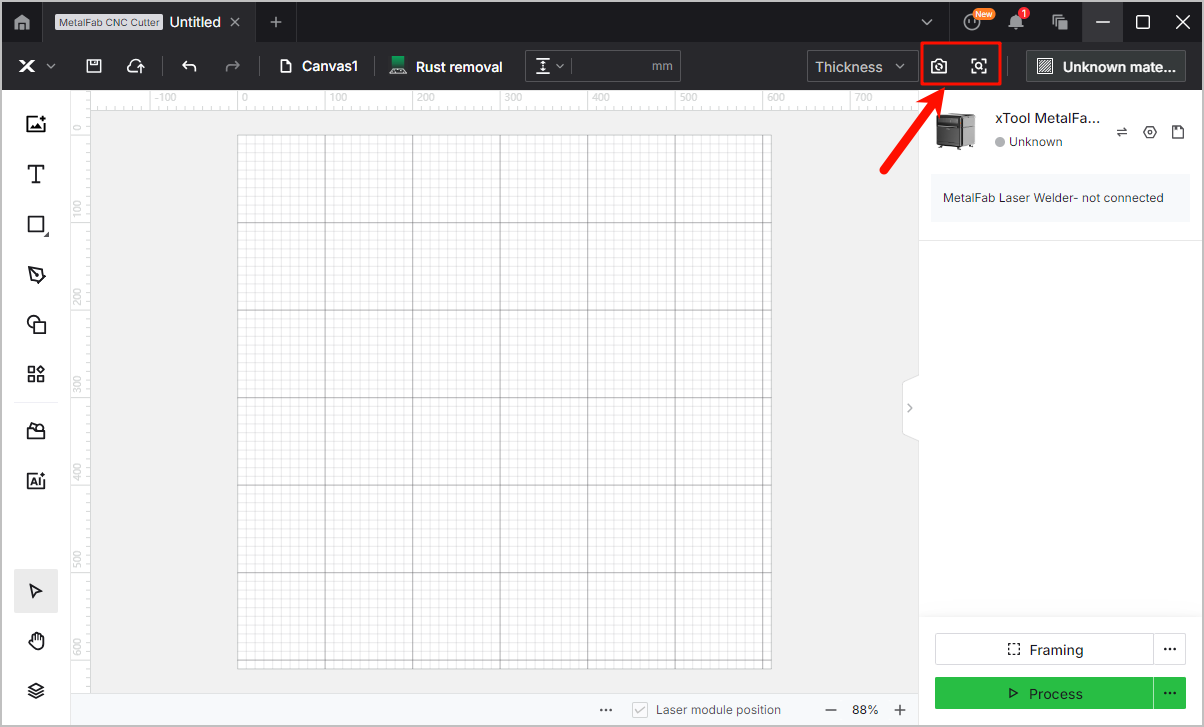

- Click Refresh background or Close shot to obtain the background image.

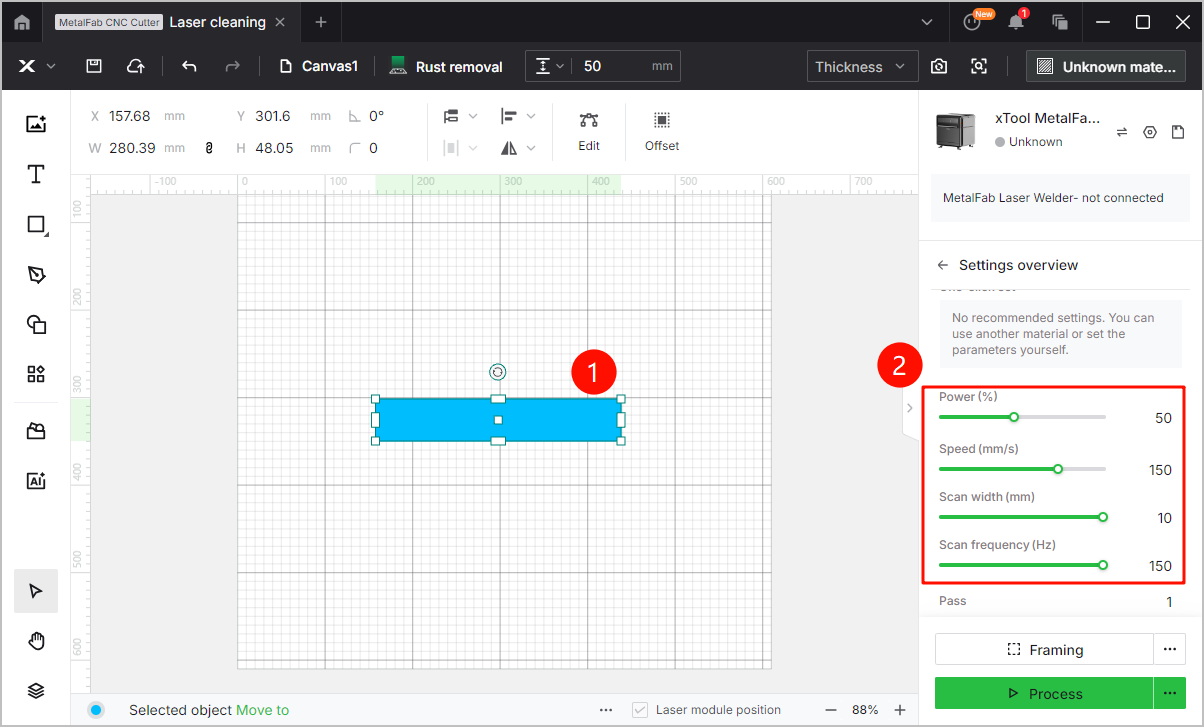

- Import a cleaning path file or create an object covering the area to be cleaned.

- Click the object and configure settings by adhering to the range mentioned below:

- Power: 50% – 70%

- Speed: 200 mm/s – 300 mm/s

Step 4: Prepare the shielding gas

- Prepare nitrogen, argon (recommended), or compressed air as the shielding gas.

- Set the air pressure of the shielding gas within 0.5 MPa to 0.6 MPa.

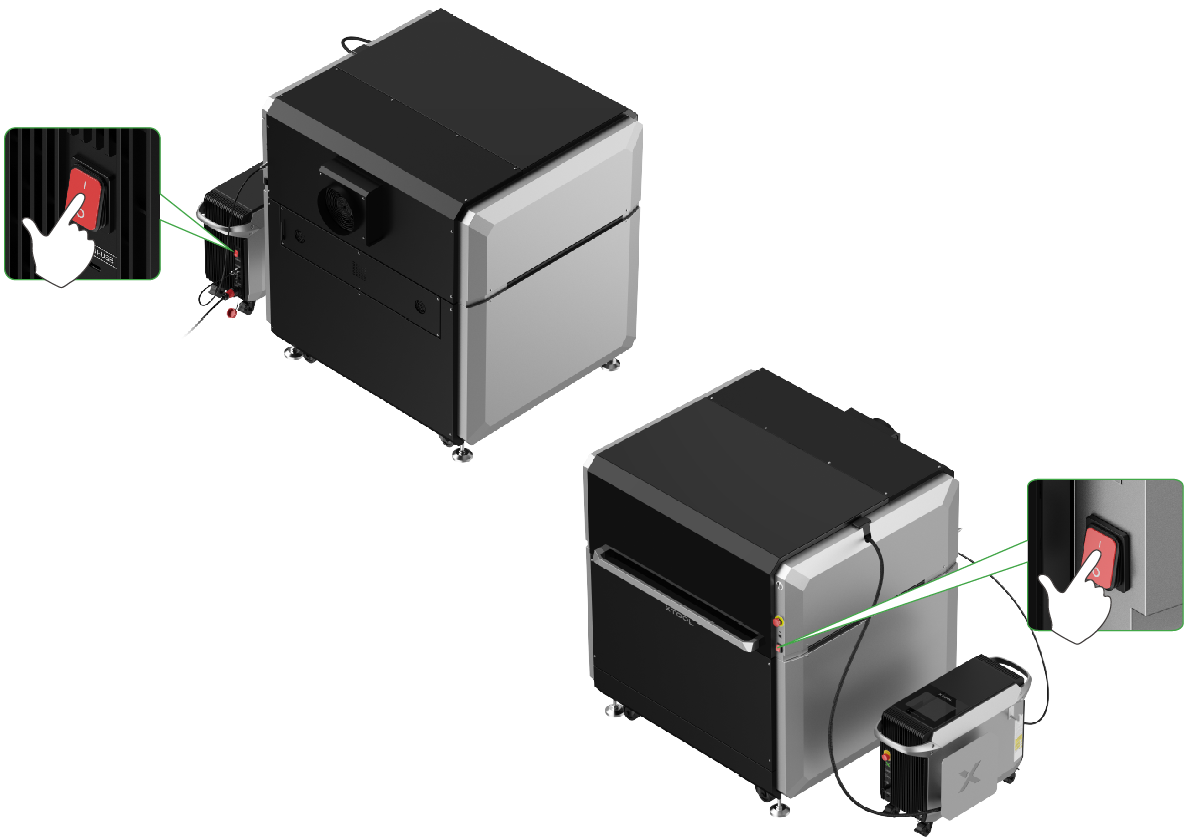

Step 5: Start laser cleaning

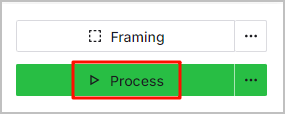

- Click Process.

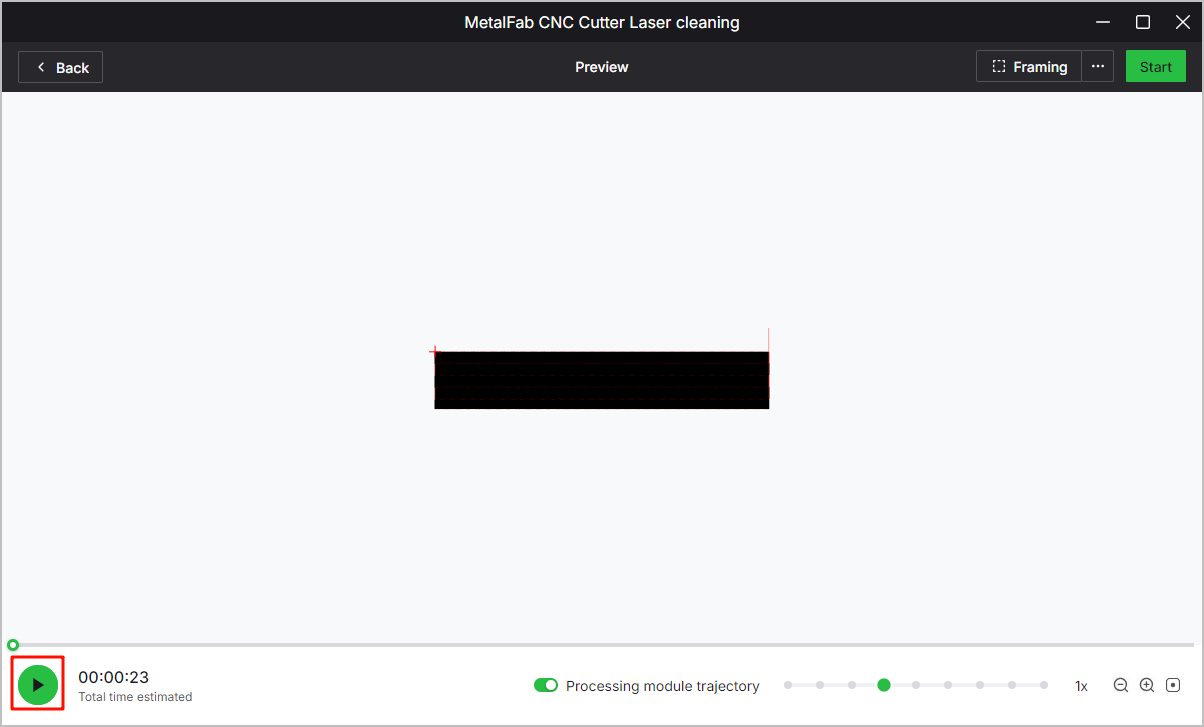

- You can prereview the processing path and time in the Preview page.

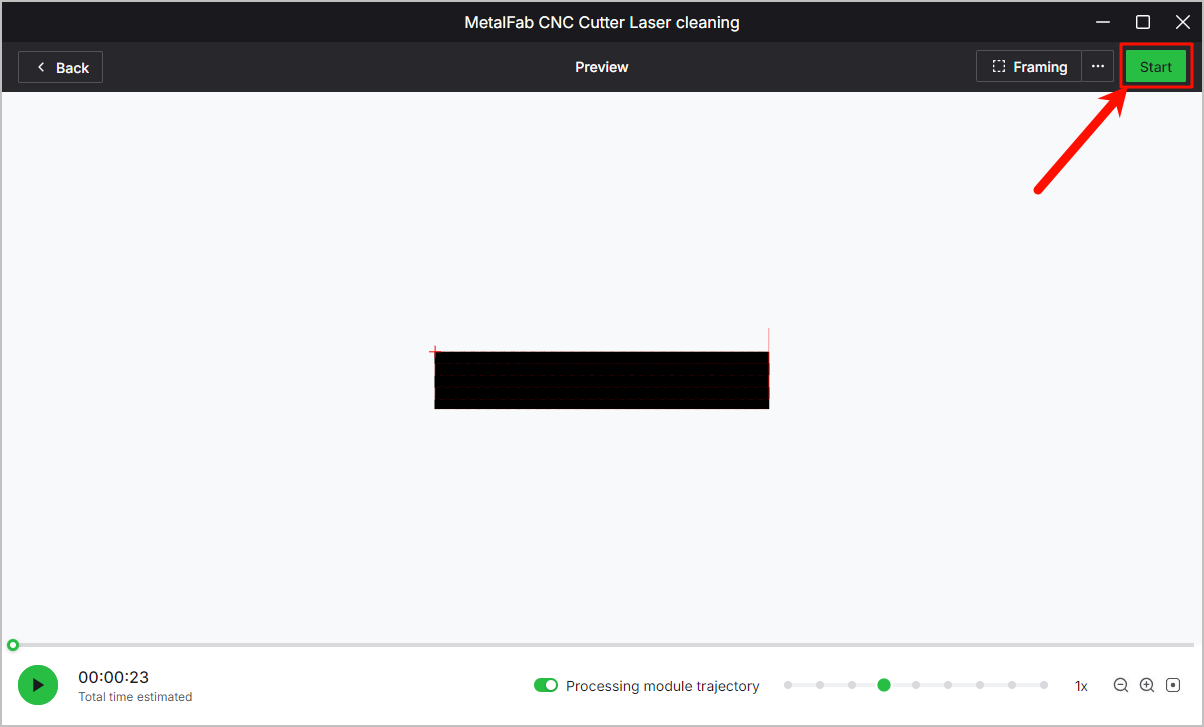

- Click Start.

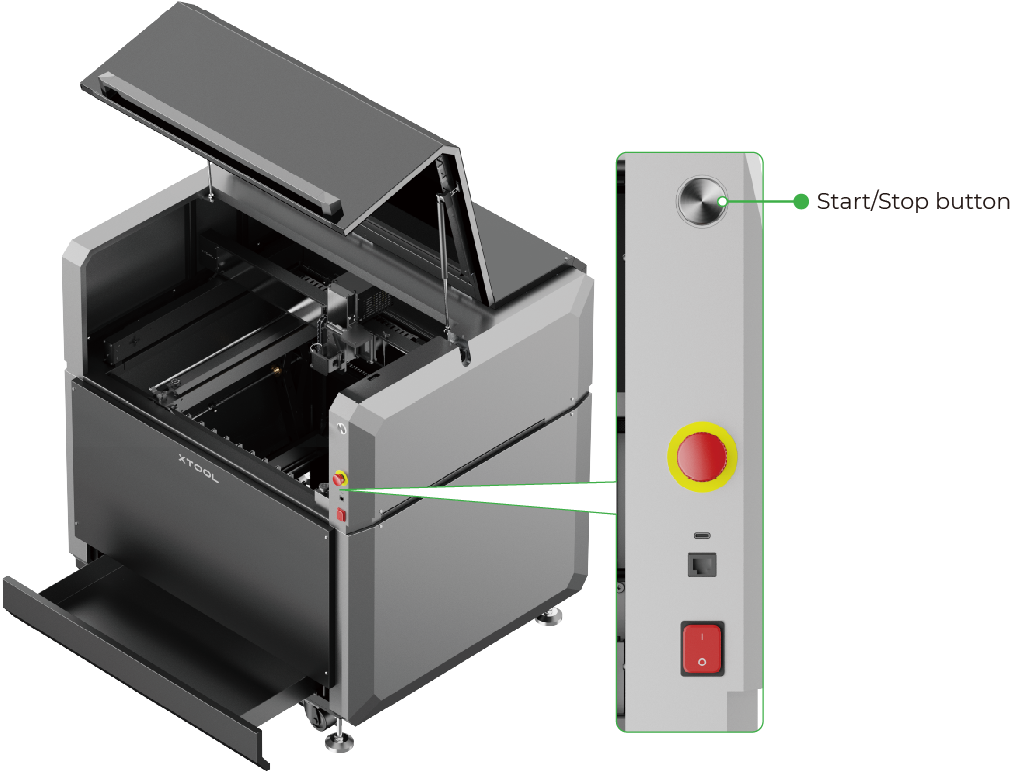

- Push the start/stop button to start the processing.

Preview

Was this page helpful?

2 out of 2 found this helpful

Help Ticket

Use this help ticket to submit your issue. We will respond within 1 business day

Submit a Ticket Tags

Help Ticket

Use this help ticket to submit your issue. We will respond within 1 business day

Submit a Ticket

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.