Safety Tips

Before laser welding, please be sure to watch the safety training video and wear personal protective equipment (laser safety goggles/helmet, mask/face shield, heat-resistant gloves).

Gas Suggestions

Gas Suggestions for xTool MetalFab | ||||

Processing Type | Material Type | Recommended Gas | Recommended Pressure | Recommeded Nozzle |

CNC Cutting | Stainless Steel | 99.99% Nitrogen or | Over 87 PSI (0.6 MPa) | Ordinary cutting nozzle |

Stainless Steel (2mm-5mm) | 99.99% Nitrogen or | Over 174 PSI (1.2 MPa) | Ordinary cutting nozzle | |

Over 87 PSI (0.6 MPa) | SaveGas™ Nozzle | |||

Titanium Alloy TC4 (1mm) | 99.99% Argon | Over 174 PSI (1.2 MPa) | Ordinary cutting nozzle | |

Titanium Alloy TC4 (2mm-5mm) | SaveGas™ Nozzle | |||

Carbon Steel (2mm-10mm) | 99.99% Oxygen | 8.7 PSI-10.2 PSI | Double-layer Nozzle & focus extension tube | |

CNC Cleaning | Stainless Steel | 99.99% Nitrogen or | 87 PSI-116 PSI | CNC Cleaning Nozzle |

Welding | Stainless Steel | 99.99% Nitrogen or | 15-30L/min flow rate or 14.5 PSI-29 PSI (0.1 MPa-0.2 MPa) pressure | Welding Nozzles |

Handheld Cleaning | Cleaning Nozzle | |||

Handheld Cutting | 99.99% Nitrogen or | Over 116 PSI (0.8 MPa) pressure | Handheld Cutting Tip | |

Welding Wire Options

Welding wire or not?

Not all welding processes require welding wires.

- For thin plates less than 1mm, the base material can be melted directly to form the weld seam without the need for additional welding wires.

- If the weld seam is relatively small, it can also be welded using autogenous welding, which does not require additional welding wires.

Welding wire material

The basic principle is that the base sheet and the welding wire should be of the same material.

Materials | Grades | Recommended Wire | Shielding Gas |

Stainless Steel | 304 Stainless Steel | 308L | 99.99% Nitrogen or 99.99%Argon

|

316 Stainless Steel | 316L | ||

430 Stainless Steel | 309L | ||

Carbon Steel | Q235, 20# | ER70S-6 | |

45# | ER50-6 | ||

Galvanized Sheet | DX51D, DX52D

| ER70S-G / ER70S-6 | |

Aluminum

| 1060 | 6061 | |

6061, 6063 | 4043 | ||

5052 | 5356 | ||

Brass | H62 | S221 |

Welding wire diameter

Please choose welding wire of proper diameters for metals of different thickness

- The diameter of the welding wire should not be smaller than the gap of the weld, and the thickness of the workpiece is not recommended to be less than the diameter of the wire.

- xTool MetalFab laser welder now supports wires of 0.8mm, 1.0mm, 1.2mm, 1.6mm.

- For metals≥4mm, it's recommended to use 1.2mm wire. For metals of 2-3mm, it's recommended to use 1.2mm wire. For metals ≤1mm. it's recommended to use 0.8mm wire. This is only for recommendation, the final choice should be based on the welding results and demands.

Check Before Welding

Welding Focus Position

Confirm the welding nozzle scale is the same as the suggested value of system settings.

Click to see how to adjust the welding focus position>>

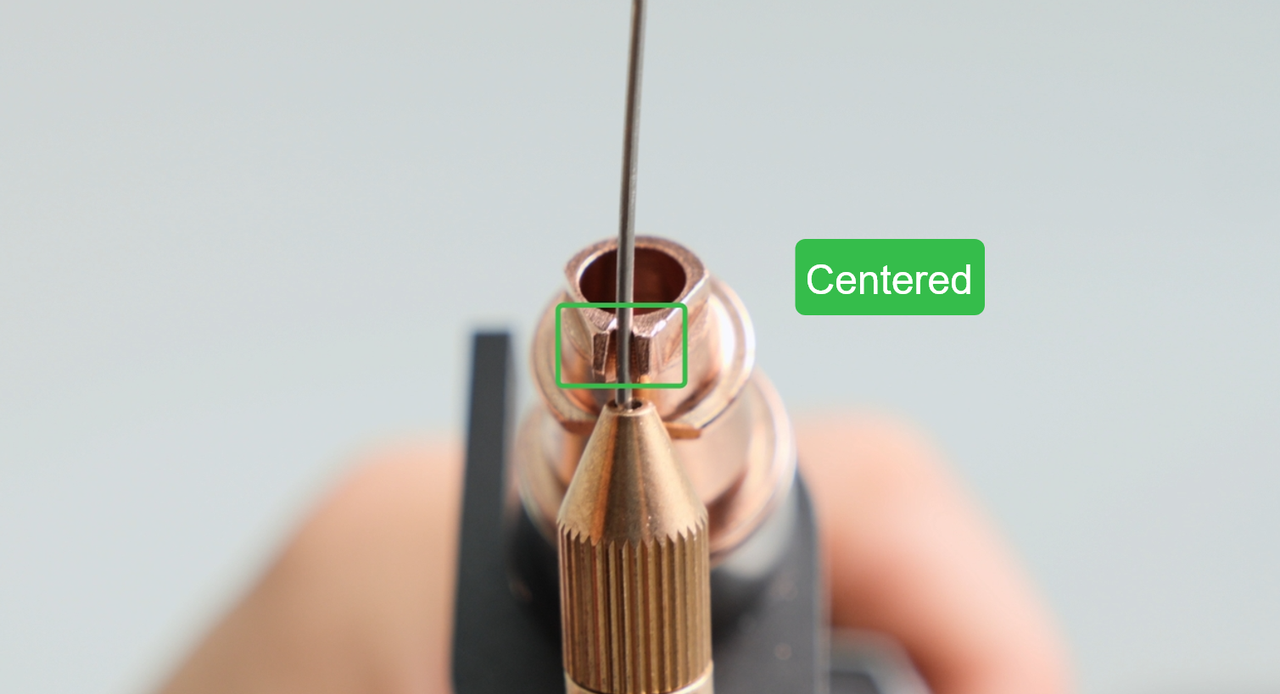

Welding wire position

When installing the wire feeding tube, ensure that the welding wire fits snugly into the groove of the wire feeding nozzle to prevent the wire from being offset.

Click to see how to adjust the wire feeding tube>>

|

|

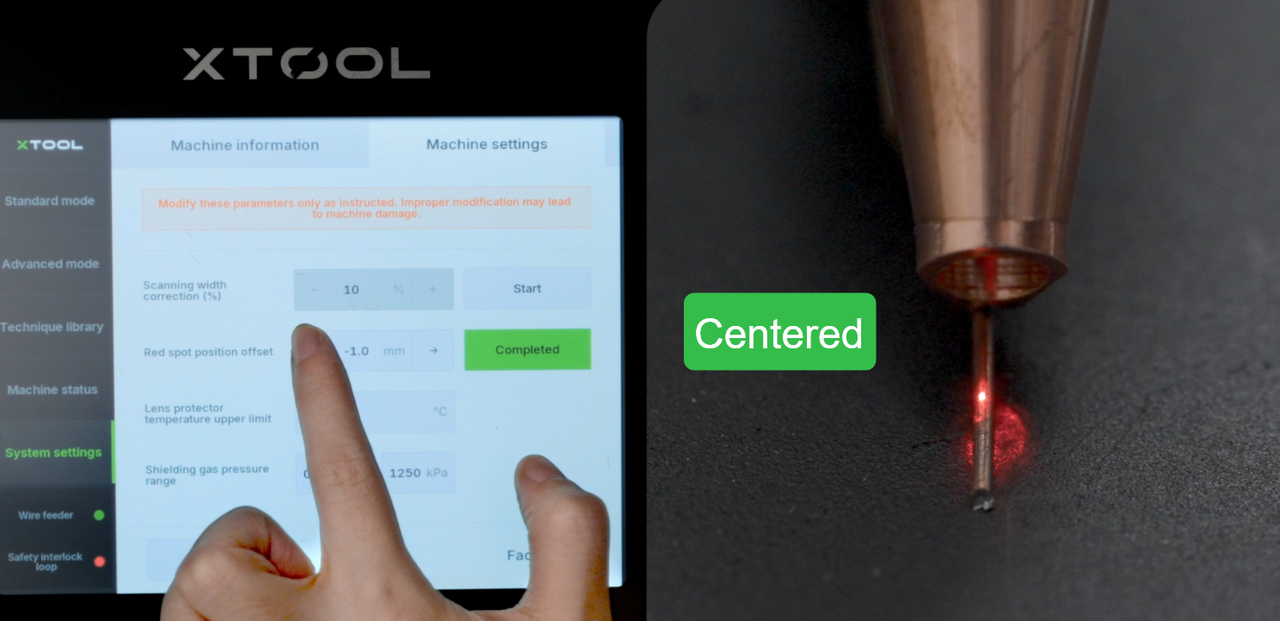

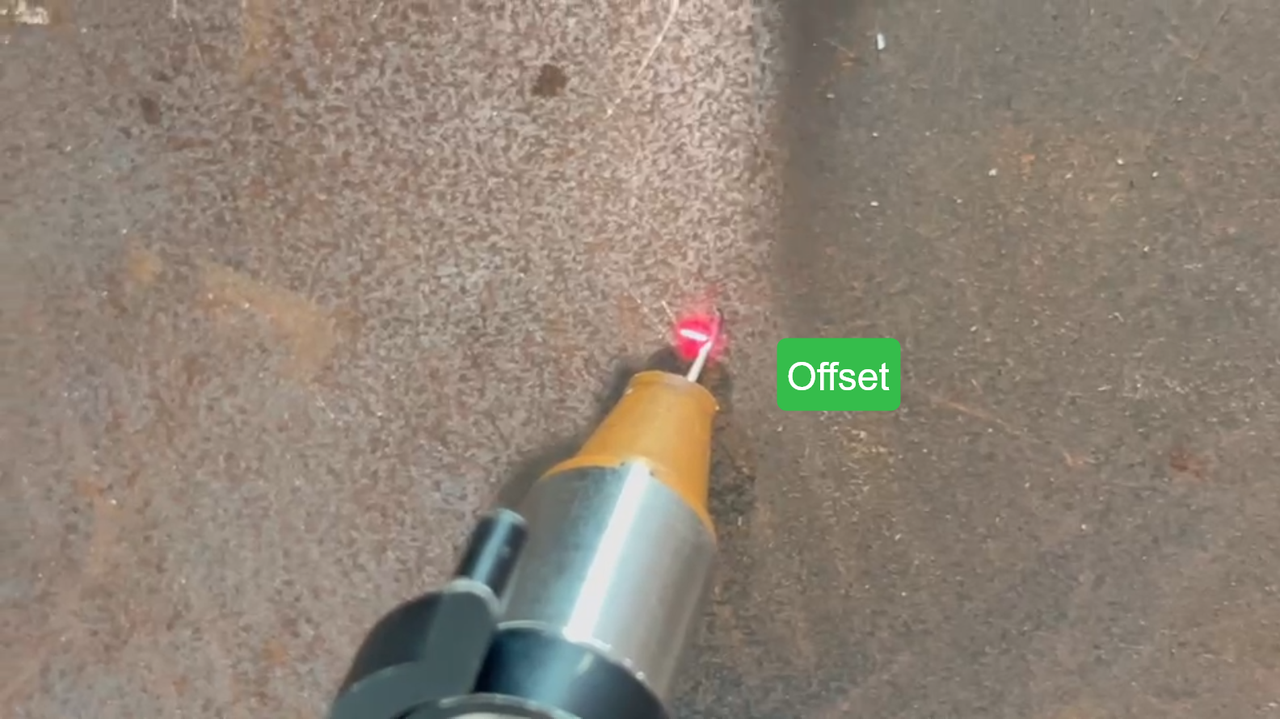

Red light position

Before welding, check that the welding wire is aligned with the center of the red light.

Click to see how to calibrate the red light>>

|

|

Protective lens

Check if the lens is dirty or damaged.

Click to see how to check and replace lens>>

Welding Tips

- Choose the proper welding parameters according to your demands. (How to Choose Welding Parameters?)

- The welding nozzle of the welding gun should be inclined at a 45° angle to the weld seam.

Correct angle:

|

|

Incorrect angle:

|

|

- The welding wire must not deviate from the weld seam.

- During wire feeding, do not pull the wire with your hand; the wire feeder will drive the welding gun automatically.

|

|

Hands pulling the wire, too high speed | Auto wire feeding, proper speed |

- After welding, manually lift the gun to avoid wire sticking.

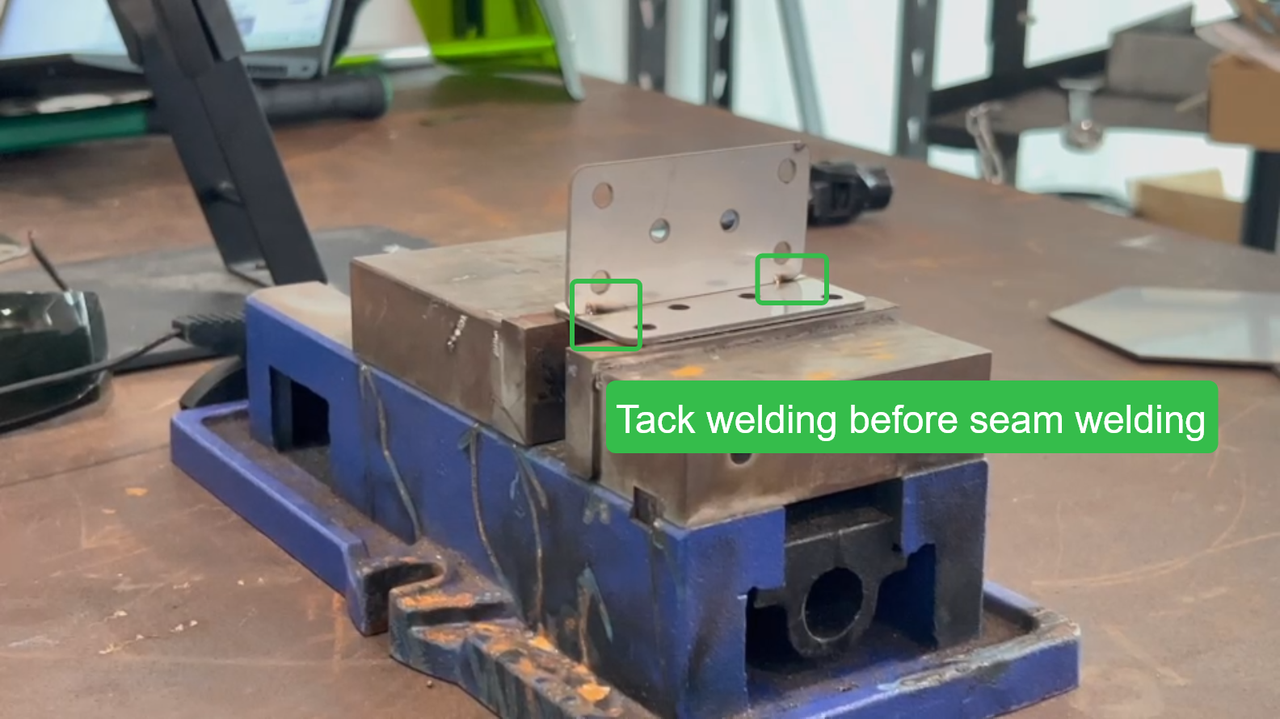

- It is recommended to perform tack welding first, followed by continuous welding.

- When welding, leave space for deformation.

|

|

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.