Issue description

During laser processing, the welding head cannot emit laser beams to melt, cut, or clean the workpieces.

Possible causes

- On the touchscreen, the lasering function is not enabled.

- During laser processing, the grip sensing button and trigger are not pressed at the same time.

- During laser processing, the welding head tip does not touch the workpiece.

- The safety interlock loop between the welding head and the workpiece is not closed.

- On the welding head, the laser beams hit the inner wall of the nozzle.

Troubleshooting procedure

Please follow these steps in order.

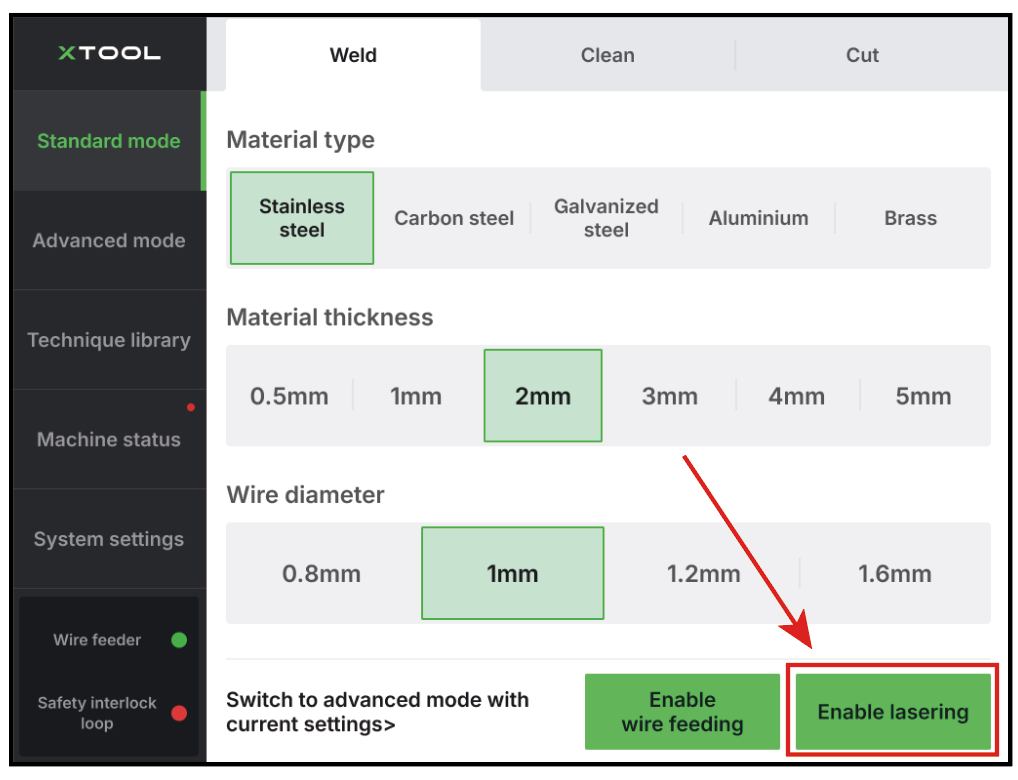

STEP 1: Check if Enable lasering is turned on

On the touchscreen, check if the Enable lasering button is green. If not, tap the Enable lasering button to turn it on.

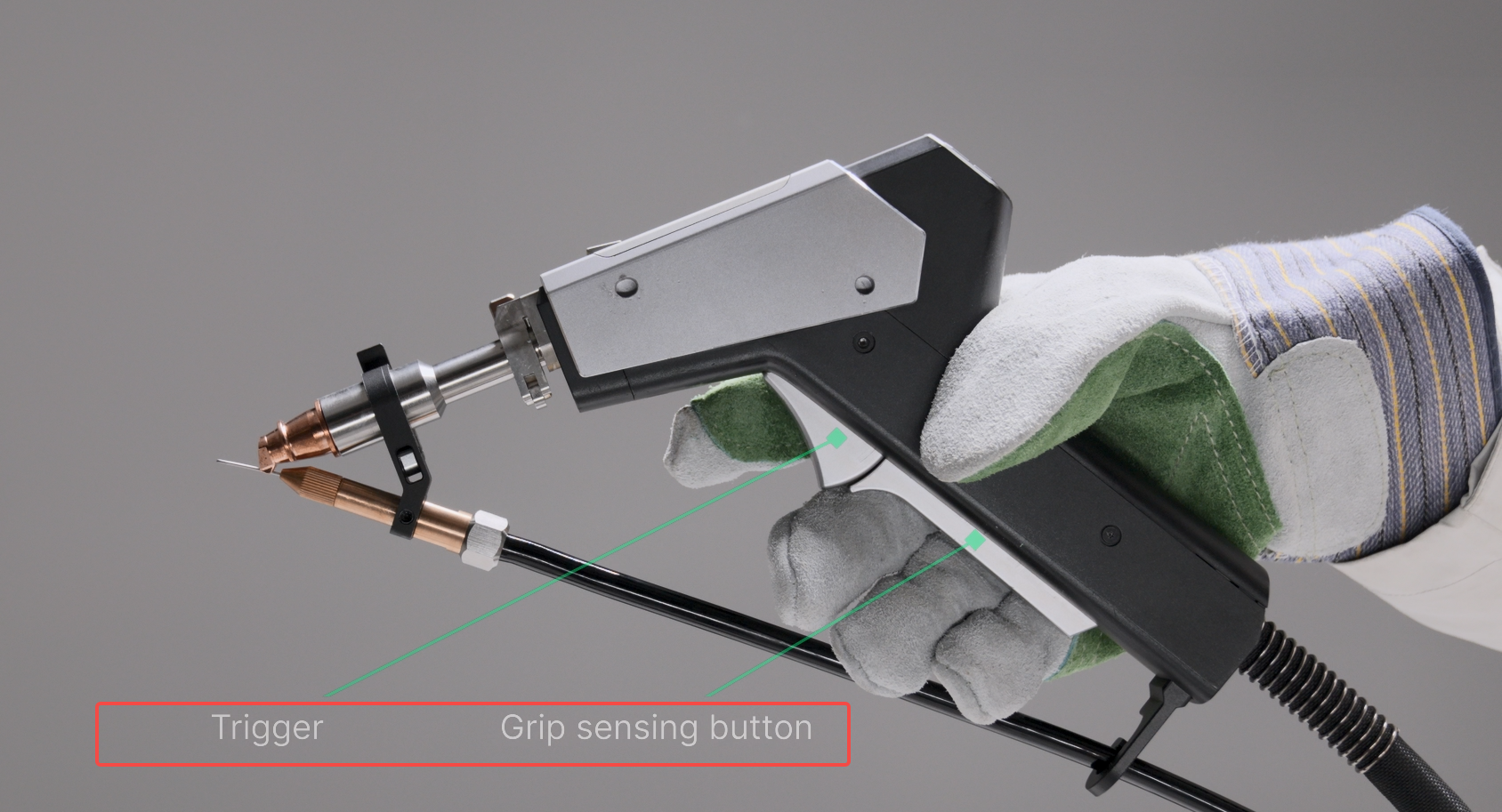

STEP 2: Press the grip sensing button and trigger at the same time

During laser processing, press and hold the grip sensing button and trigger at the same time to emit laser beams.

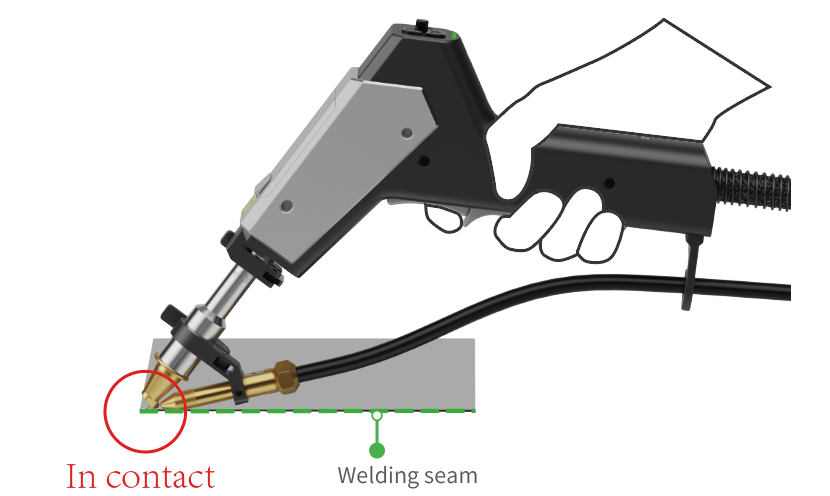

STEP 3: Ensure that the welding head tip contacts the workpiece

During laser processing, hold the welding head with its tip in contact with the workpiece.

STEP 4: Check the safety interlock loop

Note: A safety interlock loop exists between the welding head, the workpiece, and the main unit.

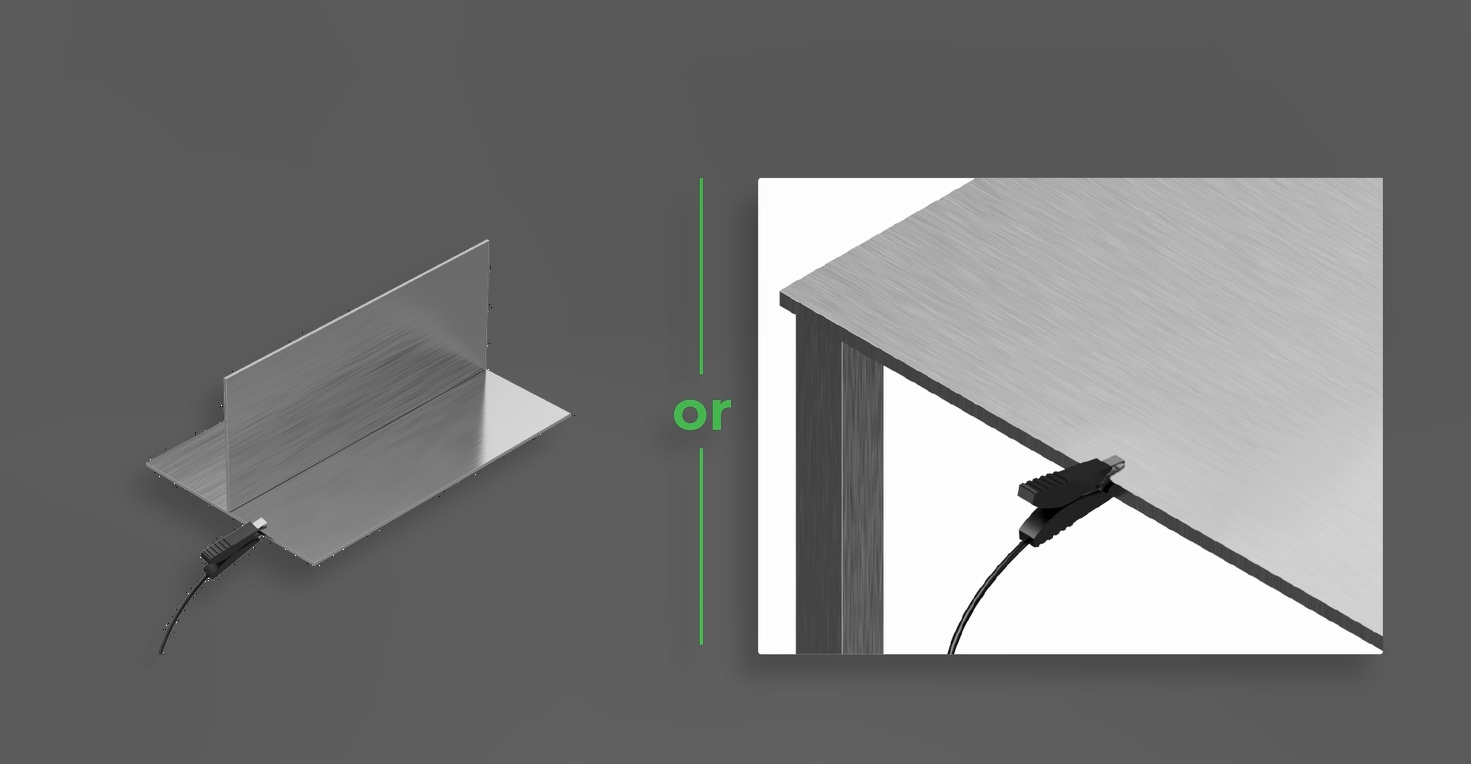

(1) Check if the workpiece sensing cable properly connects the workpiece to the main unit. If not, insert its connector end into the port for the workpiece sensing cable, and attach its clamp to the workpiece or a conductive object connected with the workpiece, such as a metal base or a metal desktop.

|

|

|

Workpiece sensing cable | Insert into the port for workpiece sensing cable | Clamp to the workpiece or a conductive object connected with the workpiece |

(2) Check if the part in contact with the clamp of the workpiece sensing cable is conductive. If the contacting part is dirty or oxidized, covered with grease, paint, or rust, it may fail to conduct electricity and close the safety interlock loop. In this case, polish the contacting part to ensure good electrical conductivity.

(3) With the workpiece sensing cable connected to the workpiece and the welding head nozzle in contact with the workpiece, check the touchscreen to see if there is a green dot near "Safety interlock loop" in the bottom-left corner. And when you lift the welding head away from the workpiece, the green dot turns into red.

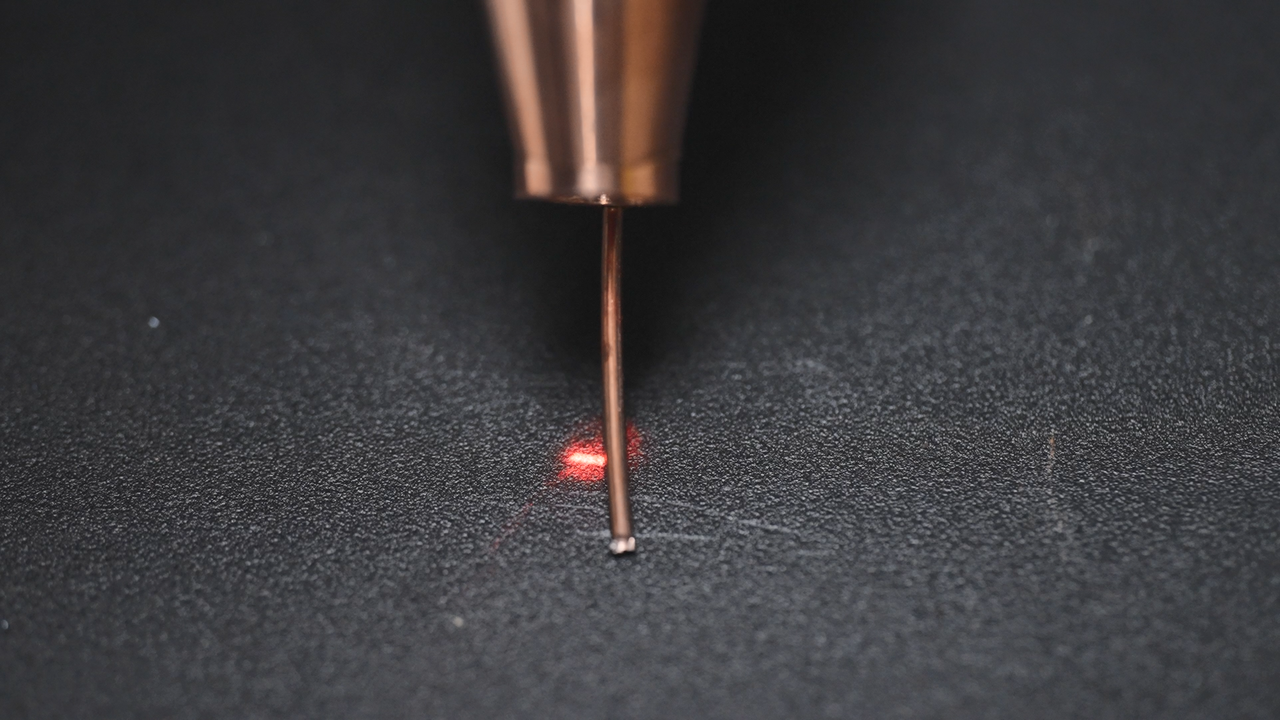

STEP 5: Check if the welding head emits a clear and integral red light spot

When the machine is turned on, the guide laser is automatically turned on and emits a red light spot that indicates where the laser beams will hit during laser processing. Therefore, if the welding head emits a clear and integral red light spot, it indicates that the laser beams can come out from the aperture smoothly.

If the welding head does not emit a clear and integral red spot, please calibrate the red spot position. For detailed instructions, see the following tutorial:

Still experiencing issues?

Should the issue persist after completing the preceding steps, submit a ticket via the "Submit a Ticket" button in the "Help Ticket" section below. The standard response time for xTool Customer Service is one business day.

For a prompt resolution, please include the following details:

- Issue description: A detailed explanation of the observed problem.

- Video evidence: Attach a video demonstrating the issue, where applicable.

- Troubleshooting performed: Any troubleshooting steps you have already attempted, along with their results.

This information is crucial for xTool technical support engineers to provide timely assistance.

Documentation feedback

Help improve this content by providing feedback. If this content did not meet your requirements, select "No" in the "Was this page helpful?" section below. Include specific details about what was unclear or missing in the pop-up suggestion box. Feedback submissions are reviewed by xTool technical writers to enhance future documentation.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.