Official Guide

User Manual

xTool MetalFab CNC Cutter User Manual

xTool MetalFab Laser Welder User Manual

xTool Selected Air Compressor User Manual

xTool Selected Air Dryer User Manual

Unboxing Videos

xTool MetalFab Laser welder:

xTool MetalFab CNC cutter:

Safety Training Video

Laser Welder (1200w)

Hardware

1. Space Requirements

Please prepare sufficient space for the xTool Metalfab laser welder.

- The whole packaging dimensions are 35.43 in × 31.50 in × 28.74 in (900 mm × 800 mm × 730 mm) , the welder dimensions are 12.87 in × 28.66 in × 20.16 in (327 mm × 728 mm × 512 mm), and the wire feeder dimensions are 9.13 in × 26.14 in × 16.42 in (232 mm × 664 mm × 417 mm).

- Please ensure to reserve at least 19.69in (50 cm) of space on all four sides when unpacking.

- Please reserve at least 11.81in to 19.69 in(30-50 cm) of space at the front and back for heat dissipation.

- Additionally, space for the gas generation device and welding platform must be reserved (welding requires the use of gas cylinders or a gas generator).

2. Electricity Environment

- xTool MetalFab laser welder can work with the voltage of 200-240v, operating at full power with approximately 4200W, the maximum current is 21A. It is recommended that users connect it to an independent circuit of 220V-25A or higher.

- For US, we provide a NEMA6-50p or NEMAL6-30 plug, for others, we provide power cables, so an electrician is required to install the correct circuit.

- Please confirm the maximum load capacity of your circuit:

a. If used in a fixed location, an electrician should verify the voltage and current-carrying capacity of the site's wiring.

b. If the requirements are met, an electrician can connect the power cable terminals to an air switch that meets the full power usage requirements. - If using a mobile power source, ensure that:

a. The output power of the mobile power source can reach 4200W or more.

b. The mobile power source has a socket that meets this power requirement.

c. The laser welder needs to be connected to a plug that meets the requirement of max. current.

d. The laser welder requires an electrostatic grounding wire to be connected (the mobile power source does not have grounding).

Must-know Safety Notes:

- The electricity circuit must be operated and installed by a qualified electrician.

- Ensure that the current-carrying capacity of your circuit meets the requirements. Do not connect the product to a standard household circuit, as it may damage both the product and the circuit.

- Ensure that the welder is powered separately. Do not use it with other high power equipment on the same circuit.

- To ensure safety, it is recommended that you install a 30A/50A circuit breaker between the power supply and xTool MetalFab Laser Welder 1200W according to your electrical environments. Please refer to local electrical safety requirements to choose the breaker. (xTool MetalFab 1200w laser welder has a 25A breaker inside the machine. )

3. Gas Preparation

For welding and handheld cutting or cleaning, here's the general suggestion.

Gas Suggestions for xTool MetalFab | ||||

Porcessing Type | Material Type | Recommended Gas | Recommended Pressure | Recommended Nozzle |

Welding | Stainless Steel Aluminum Brass Carbon Steel Galvanized Sheet | 99.99% Nitrogen or 99.99% Argon | 15-30L/min flow rate or 14.5 PSI-29 PSI (0.1 MPa-0.2 MPa) pressure | Welding Nozzles (included in laser welder package) |

Handheld Cleaning | Cleaning Nozzle (included in laser welder package) | |||

Handheld Cutting | 99.99% Nitrogen or 99.99% Argon or Compressed Air | Over 116 PSI (0.8 MPa) pressure | Handheld Cutting Tip (included in laser welder package) | |

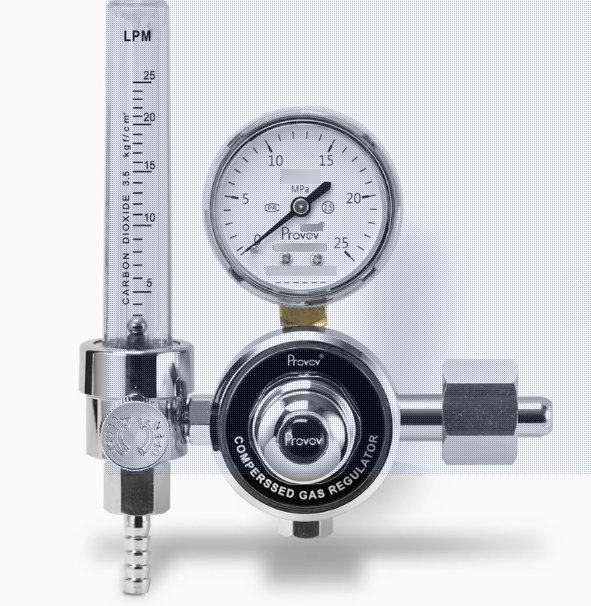

4. Flow Valve/ Pressure Reducing valve

- It is recommended that users connect a flow valve for welding and handheld cleaning to make it easier to control the flow rate. It is recommended to use a gas flow of 15L-30L/min.

- You can also use a pressure reducing valve and set the pressure at 0.1-0.2MPa for welding.

- Note: To install the pressure reducing valve on the gas cylinder, you will need an adjustable wrench and Teflon tape (to prevent gas leaks).

|

|

|

|

Flow valve | Pressure valve | Adjustable wrench | Teflon tape |

5. Gas cylinder securing device

For safety, please secure the gas cylinder using a cart or similar tools when in use.

|

|

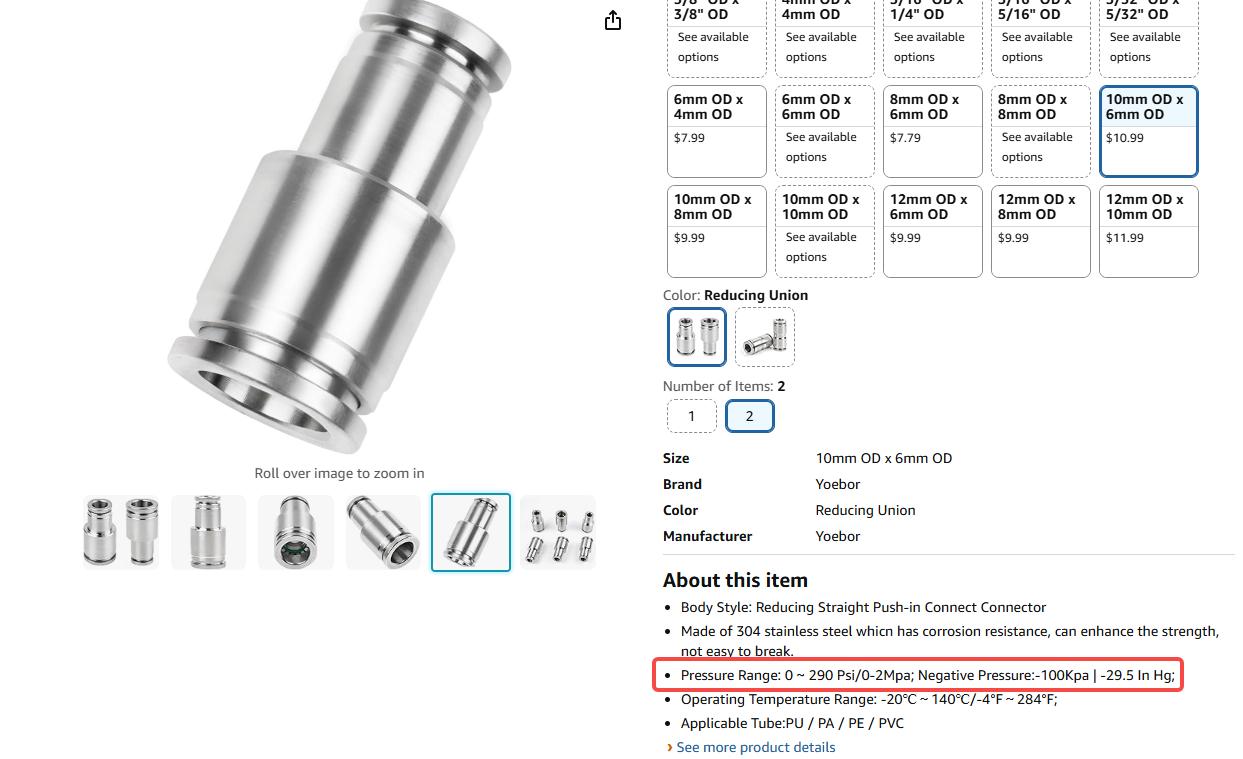

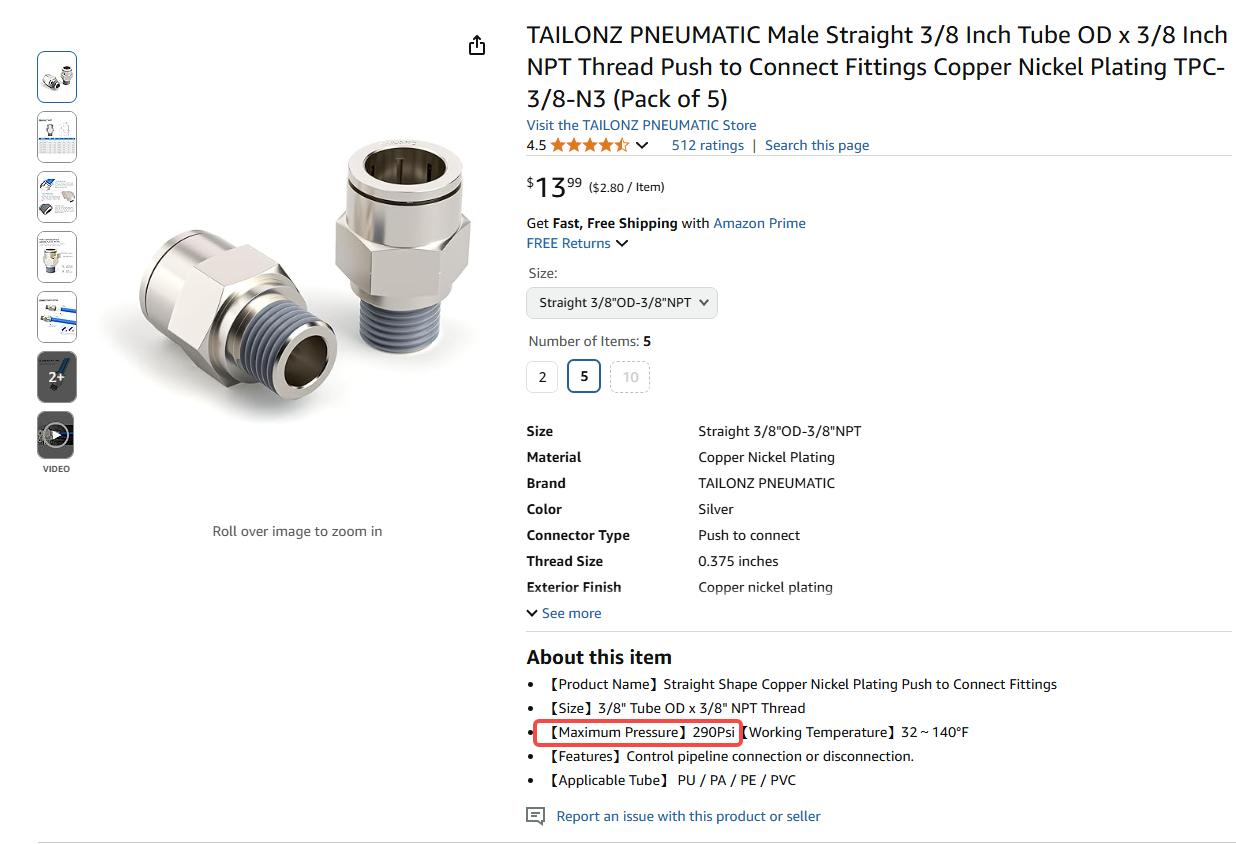

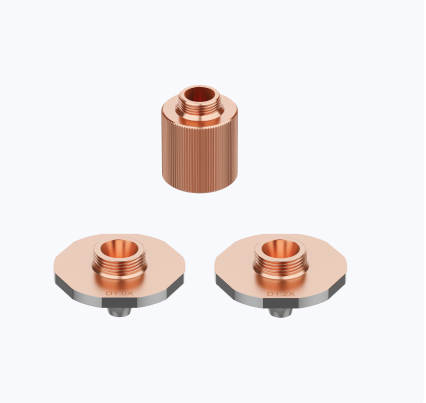

6. Air hose adapter

xTool MetalFab laser welder applies an inlet air hose of 3/8in (10mm) outer diameter and uses a push-to-connect structure. If your nitrogen cylinder's outlet diameter is not 10 mm, an adapter is required.

For example, with a U.S. standard 1/4in nitrogen cylinder, you need a 1/4in to 3/8in adapter.

Please choose a pure metal adapter and ensure its pressure capacity is above 174 PSI (1.2 MPa).

1/4in hose to 3/8in hose |

1/4in pressure valve to 3/8in hose |

7. Welding Platform

Please prepare a welding metal table/platform.

If conditions permit, please prepare some welding clamps and other tools to avoid welding directly on the metal table, which could cause the plates to stick to the workbench.

8. Exhaust system

Cutting and welding will produce metal smoke and dust, it is recommended to have an exhaust system

xTool MetalFab CNC cutter comes with an exhaust fan with a maximum airflow of 509 CFM. In actual cutting scenarios, the measured airflow is 325 CFM at an outlet airspeed of 4.9 m/s. If connected to an air purifier, the purifier’s airflow must exceed 325 CFM.

9. Welding wire

- xTool MetalFab laser welder comes with a spool of 1mm stainless steel wire for stainless steel welding.

- Please prepare the appropriate welding wire for other materials.

Materials | Grades | Recommended Wire | Shielding Gas |

Stainless Steel | 304 Stainless Steel | 308L | 99.99% Nitrogen or 99.99%Argon

|

316 Stainless Steel | 316L | ||

430 Stainless Steel | 309L | ||

Carbon Steel | Q235, 20# | ER70S-6 | |

45# | ER50-6 | ||

Galvanized Sheet | DX51D, DX52D | ER70S-G / ER70S-6 | |

Aluminum | 1060 | 6061 | |

Brass | H62 | S221 |

- Please choose welding wire of proper diameters for metals of different thickness

Please choose welding wire that matches the material of the workpiece. The diameter of the welding wire should not be smaller than the gap of the weld, and the thickness of the workpiece is not recommended to be less than the diameter of the wire. The final choice should be based on the welding results and demands.

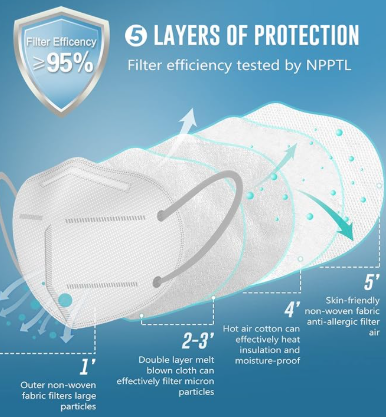

10. Personal Protective Equipment

xTool offers OD7+ 1064 nm laser safety goggles, heat-resistant golves in the laser welder package.

Please prepare some N95/KN95/P100 masks.

|

|

OD7+ goggles (provided) | Heat-resistant golves(provided) |

|

|

N95/KN95 mask (self-supplied) | P100 mask (self-supplied) |

CNC Cutter

The MetalFab CNC cutter can't work without the MetalFab laser welder.

Hardware

1. Space Requirements

Please prepare sufficient space for the xTool Metalfab CNC cutter.

- The whole packaging dimensions are 59.06 in × 44.49 in × 43.70 in (1500 mm × 1130 mm × 1110 mm) , the cutter dimensions are 46.38 in × 45.59 in × 48.43 in (1175mm × 1157mm × 1230mm).

- Please ensure to reserve at least 39.37in(100 cm) of space on all four sides when unpacking.

- Please reserve at least 11.81 to 19.69 in(30-50 cm) of space at the front and back for heat dissipation.

- Additionally, space for the gas generation device must be reserved (cutting requires the use of gas cylinders, a gas generator or an air compressor system). For xTool solution, the air compressor demensions are 18.11 in × 20.87 in × 10.63 in(460 mm × 530 mm × 270 mm), the air dryer dimensions are 15.83 in × 13.98 in × 8.94 in (402 mm × 355 mm × 227 mm).

- Note: The CNC cutter supports passthrough function allowing for processing longer materials. If needed, please reserve space in advance.

2. Drawer Protection Materials

To prevent thermal deformation of the drawer during prolonged processing, please add sand or water, or place a non-reflective metal plate in the drawer to serve as insulation.

- The thickness of the sand should be >= 3mm, the recommended particle size is 1-3mm; the thickness of the water should be >= 10mm.

|

|

- The metal plate can be 2mm stainless steel; do not use aluminum, brass, or other highly reflective materials.

3. Electricity Environment

- xTool MetalFab CNC Cutter requires 2.5 A, 100 V – 240 V single phase AC power.

- xTool MetalFab laser welder operates at full power with approximately 4200W, the maximum current is 21A. It is recommended that users connect it to an independent circuit of 220V-25A or higher.

- xTool air compressor requires 200-240v voltage, 2200W rated power. The air dryer requires 200-240v (EU/UK) or 100-120v (US/CA) voltage, 380W rated power.

- The electricity circuit must be operated and installed by a qualified electrician.

4. Gas Preparation

- For CNC cutting, nitrogen/argon/oxygen/compressed air are usually used for differnet scenarios.

- If you use the air compressor, please add an air dryer to ensure dry, clean air going into the airline.

Also, to achieve best cutting effects, you should prepare an air compressor that has a rated pressure over 145 PSI (1.0MPa), air flow over 7CFM@87PSI (200L/min@0.6MPa) when using the xTool SaveGas™ nozzle.

Gas Suggestions for xTool MetalFab | ||||

Processing Type | Material Type | Recommended Gas | Recommended Pressure | Recommeded Nozzle |

CNC Cutting | Stainless Steel Aluminum Brass Carbon Steel Galvanized Sheet (0.2mm-1mm) | 99.99% Nitrogen or 99.99% Argon or Compressed Air | Over 87 PSI (0.6 MPa) |

Ordinary cutting nozzle (included in CNC cutter package) |

Stainless Steel (2mm-5mm) Aluminum (2mm-4mm) Brass (2mm-3mm) | 99.99% Nitrogen or 99.99% Argon or Compressed Air | Over 174 PSI (1.2 MPa) | Ordinary cutting nozzle (included in CNC cutter package) | |

Over 87 PSI (0.6 MPa) | SaveGas™ Nozzle (included in CNC cutter package) | |||

Titanium Alloy TC4 (1mm) | 99.99% Argon | Over 174 PSI (1.2 MPa) | Ordinary cutting nozzle (included in CNC cutter package) | |

Titanium Alloy TC4 (2mm-5mm) | SaveGas™ Nozzle (included in CNC cutter package) | |||

Carbon Steel (2mm-10mm) Galvanized Sheet (2mm-10mm) | 99.99% Oxygen | 8.7 PSI-10.2 PSI (0.06 MPa-0.07 MPa) | Double-layer Nozzle & focus extension tube (add-on) | |

CNC Cleaning | Stainless Steel Aluminum Brass Carbon Steel Galvanized Sheet | 99.99% Nitrogen or 99.99% Argon | 87 PSI-116 PSI (0.6 MPa-0.8 MPa) | CNC Cleaning Nozzle (included in CNC cutter package) |

5. Pressure reducing/regulator valve

- Please prepare a pressure regulator valve that has a range of over 174 PSI (1.2MPa) to adjust the input gas pressre of the laser welder when use nitrogen/argon/air to cut or clean.

- You can also prepare a pressure regulator valve to adjust the gas pressure more conveniently. The regulator is always installed before the laser welder.

- Note: To install the pressure reducing/regulator valve on the gas cylinder, you will need an adjustable wrench and teflon tape (to prevent gas leaks).

|

|

|

|

|

Flow valve | Pressure reducing valve | Pressure regulator valve | Adjustable wrench | Teflon tape |

6. Must-have hardware for thick carbon steel or galvanized sheet cuts

For cutting 2-10mm carbon steel or galvanized sheets, please use oxygen to assist cutting and the double-layer cutting nozzle with focus extension tube.

Oxygen |

Double-layer nozzle 1.0mm/1.2mm + focus extension tube |

The gas pressure should be set precisely at 8.7 PSI-10.2 PSI (0.06-0.07MPa). There are 2 options to achieve:

• Plan A: Prepare a flow valve and a proportional valve; set the proportional valve pressure to 8.7 PSI-10.2 PSI (0.06-0.07MPa) and open the flow valve to maximum.

Flow valve

Proportional valve reference: SMC ITV2050-312BL |

• Plan B: Use a pressure valve that can precisely adjust the gas pressure to 8.7 PSI-10.2 PSI (0.06-0.07MPa), then you don't need the proportional valve.

Pressure valve with precision of 0.01MPa |

7. Gas cylinder securing device

For safety, please secure the gas cylinder using a cart or similar tools when in use.

|

|

8. Exhaust system

Cutting and welding will produce metal smoke and dust, it is recommended to have an exhaust system

xTool MetalFab CNC cutter comes with an exhaust fan with a maximum airflow of 509 CFM. In actual cutting scenarios, the measured airflow is 325 CFM at an outlet airspeed of 4.9 m/s. If connected to an air purifier, the purifier’s airflow must exceed 325 CFM.

9. Personal Protective Equipments

xTool offers OD7+ 1064 nm laser safety goggles, heat-resistant golves in the laser welder package.

Please prepare some N95/KN95/P100 masks.

|

|

OD7+ goggles (provided) | Heat-resistant golves(provided) |

|

|

N95/KN95 mask (self-supplied) | P100 mask (self-supplied) |

Software

Please install the newest XCS software on the xTool website: https://www.xtool.com/pages/software

Air Compressor & Air Dryer

1. Space Requirements

- The air compressor dimensions are 18.11 in × 20.87 in × 10.63 in (460 mm × 530 mm × 270 mm), and the air dryer dimensions are 15.83 in × 13.98 in × 10.91 in (402 mm × 355 mm × 277 mm).

- Please use them indoors.

2. Electricity Environment

- xTool air compressor requires 200-240v voltage, 2200W rated power. The air dryer requires 200-240v (EU/UK) or 100-120v (US/CA) voltage, 380W rated power.

3. Safety and Maintenance

- Always turn on the air dryer before using the air compressor, and release any residual air from the compressor tank before turning off the air dryer when not in use.

- Release the air from the compressor tank when not in use.

- Do not touch the machine head while the air compressor is in operation.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.