Getting to know the machine

Q1: What do the colors of the X indicator mean?

Status | Status indicator | Buzzer |

| Solid white

|

|

Ready for laser emission. You can press the trigger on the welding head to emit laser beams. | Blinking green slowly | |

Emitting laser. | Solid green | |

Exceptions occur or device malfunctions. | Solid red | Three consecutive beeps |

Q2: What are the functions of different copper nozzles?

Welding copper nozzle (the default copper nozzle installed on the welding head) |

| Purpose: Primarily used for welding tasks that require filler material, suitable for welding thicker materials or scenarios where enhanced weld seam strength is needed. Applicable Scenarios: Thick plate welding, high-strength welding, wide gap welding, repair welding, etc. |

Welding nozzle (for autogenous welding) | Purpose: Suitable for welding tasks that do not require filler material, typically used for thin sheet welding or precision welding. Applicable Scenarios: Thin sheet welding, precision welding, decorative welding, etc. | |

Cleaning nozzle | Purpose: Used for cleaning oxides, impurities, or residues in the welding area to ensure welding quality. Applicable Scenarios: Surface treatment before welding, weld seam cleaning, rust removal, etc. | |

Cutting tip | Purpose: Used for cutting metal materials. Applicable Scenarios: Metal sheet cutting (only capable of maintaining a cut; the finish of handheld cutting edges is relatively difficult to control). |

How to replace the cutting tip:

How to replace the copper nozzle or the cleaning nozzle:

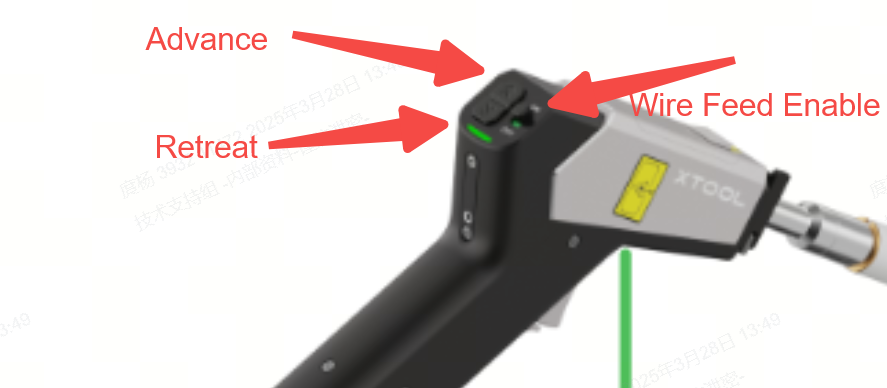

Q3: What does the wire feed enable switch on the welding head do?

A: The wire feeding enable switch provides temporary control over the welding machine's wire feeding function. This allows users to stop wire feeding during processing without having to adjust the settings on the welding machine's screen, improving user experience.

- When both the screen's "Wire Feed Enable" and the torch's "Wire Feed Enable" are on, the torch will feed wire while emitting light.

- If either "Wire Feed Enable" is off, the torch will not feed wire while emitting light.

Q4: Can one person lift xTool MetalFab Laser Welder?

A: The main unit weighs 38.2 kg, and the wire feeder is 13.2 kg (excluding wire). While one person can lift it, assistance is recommended for ease and safety.

Q5: What is the approximate cost of running the laser welder for an hour?

A: Refer to the following table for the hourly cost.

Processing mode | Nozzle type | Gas type and setting | Cost |

CNC Cutting | Standard cutting nozzle | Nitrogen: 0.8 MPa pressure | 40L nitrogen lasts 40 min |

Nitrogen: 1.2 MPa pressure | 40L nitrogen lasts 30 min | ||

Compressed air | 2.5 kWh per hour | ||

Welding | Standard welding nozzle | Nitrogen: 15L/min gas flow rate | 40L nitrogen lasts 20 hours |

Q6: Can I use a different power cable?

A: No. For optimal performance and safety, only use the power cable provided with the equipment.

Using with the Wire Feeder

Q1: Do I always need a wire feeder for welding?

A: Wire feeder and filler wire are not always needed. For thin materials (under 1 mm) or when welding small gaps, the base metal can be melted directly, using autogenous welding.

Q2: How do I choose the right wire for different materials?

Materials | Grades | Recommended Wire | Shielding Gas |

Stainless Steel | 304 Stainless Steel | 308L | Nitrogen / Argon

|

316 Stainless Steel | 316L | ||

430 Stainless Steel | 309L | ||

Carbon Steel | Q235, 20# | ER70S-6 | |

45# | ER50-6 | ||

Galvanized Steel Plate | DX51D, DX52D | ER70S-G / ER70S-6 | |

Aluminum | 1060 | 6061 | |

Brass | H62 | S221 |

Q3: Is the wire feeder compatible with different wire diameters (0.8mm, 1.0mm)?

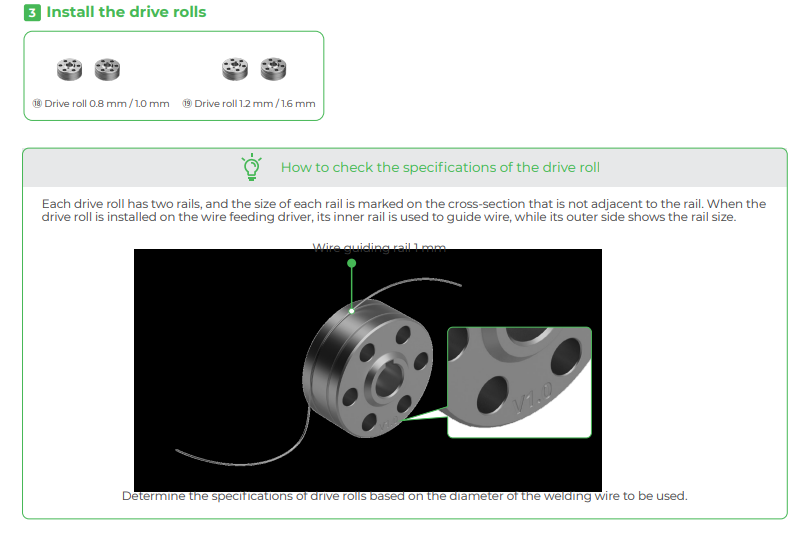

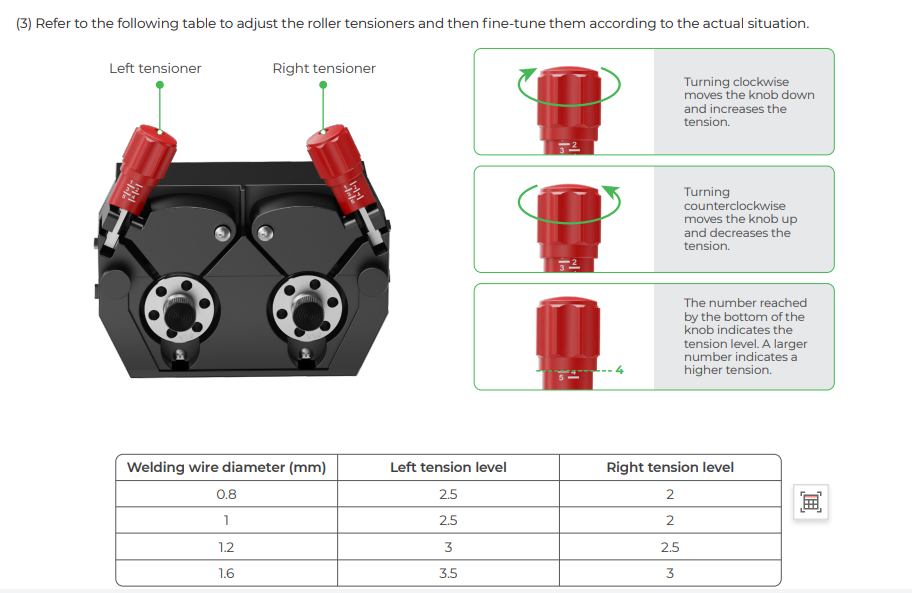

A: Yes. Please select the appropriate wire feed rollers based on the diameter of the wire being used, ensuring both rollers are the same size.

The wire feed rollers support wire diameters of 0.8mm, 1.0mm, 1.2mm, and 1.6mm.

Important: The roller tensioners must be adjusted to the correct position for each wire diameter.

Q4: How do I retract the wire properly?

A: Make sure you follow these steps when you're retracting the wire:

- Open the side door of the wire feeder.

- While pressing the retraction button, rotate the wire spool (If the wire spool is not tightened, the wires will loosen).

- When the wire is about to come out of the wire-feeding rollers, be sure to pinch the wire by hand to prevent the wires from scattering because there will be no force from the feeding rollers once the wire is out.

Using with xTool MetalFab MaxClean Accessory

Q1: What is the cleaning capability of xTool MetalFab MaxClean Accessory?

A: xTool MetalFab MaxClean Accessory is designed for cleaning various metal surfaces. Its key capabilities are summarized in the table below:

Supported material |

(Support metal: Stainless Steel, Brass, Aluminum, Galvanized Sheet, Carbon Steel) |

Processing speed | Handheld operation. Speed is affected by the user's movement speed. Recommended speed: 20 mm/s. |

Cleaning capability |

|

Processing angle (Angle relative to the contact surface) | 20° to 70° |

Scanning width | ≥ 45 mm (Measured at a 45° contact angle to the surface) |

Q2: What is the recommended gas supply for xTool MetalFab MaxClean Accessory?

A: The required gas supply is as follows:

Gas type | Compressed air or Nitrogen (Argon is not recommended due to high cost) |

Recommended pressure | 0.3 MPa to 0.6 MPa |

Accessory preparation | If using a gas cylinder, please equip it with a pressure regulator and other necessary components to ensure the shielding gas meets the above requirements. |

Note: The cleaning effectiveness of this accessory is not affected by the type of shielding gas used, which differs from weld path cleaning using the regular cleaning nozzle.

Q3: What are the application scenarios for xTool MetalFab MaxClean Accessory?

A: xTool MetalFab MaxClean Accessory is suitable for different scenarios, but its performance varies. The recommendations and cautions are summarized below:

Recommended scenario | Flat objects placed on a horizontal surface |

Acceptable with caution | Vertical surfaces with substantial height |

Not recommended | Irregularly shaped objects Vertical surfaces with very low height |

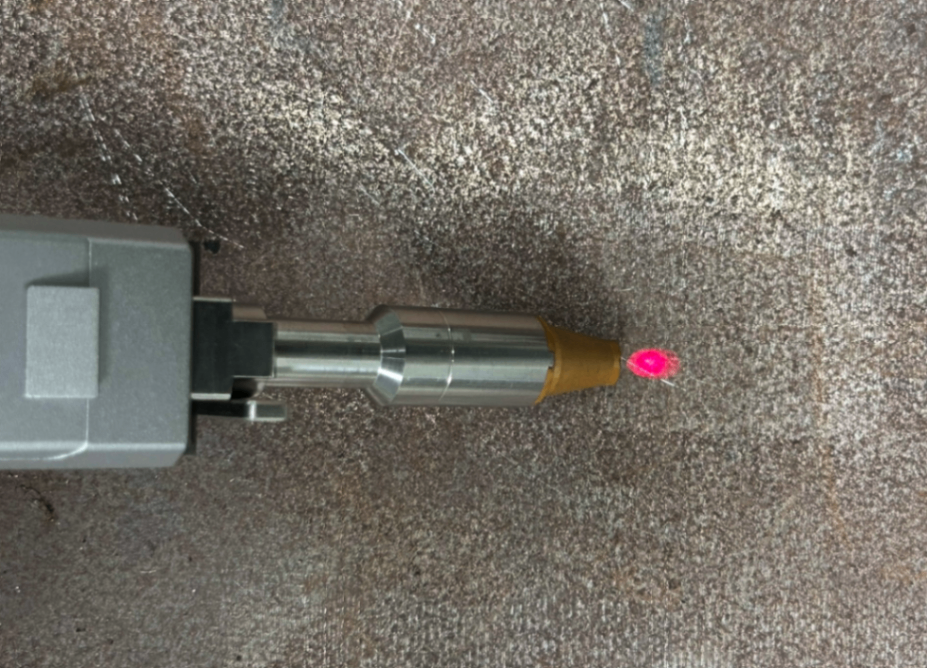

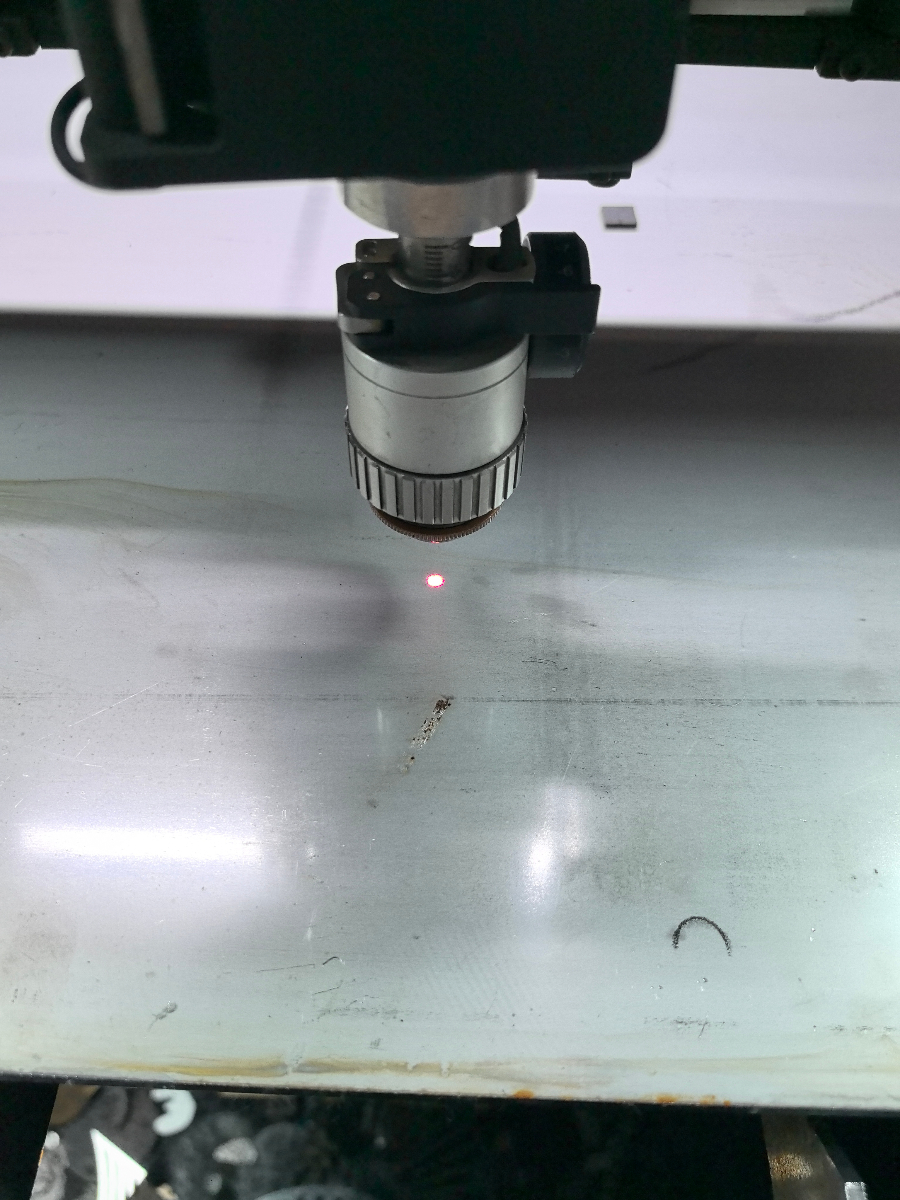

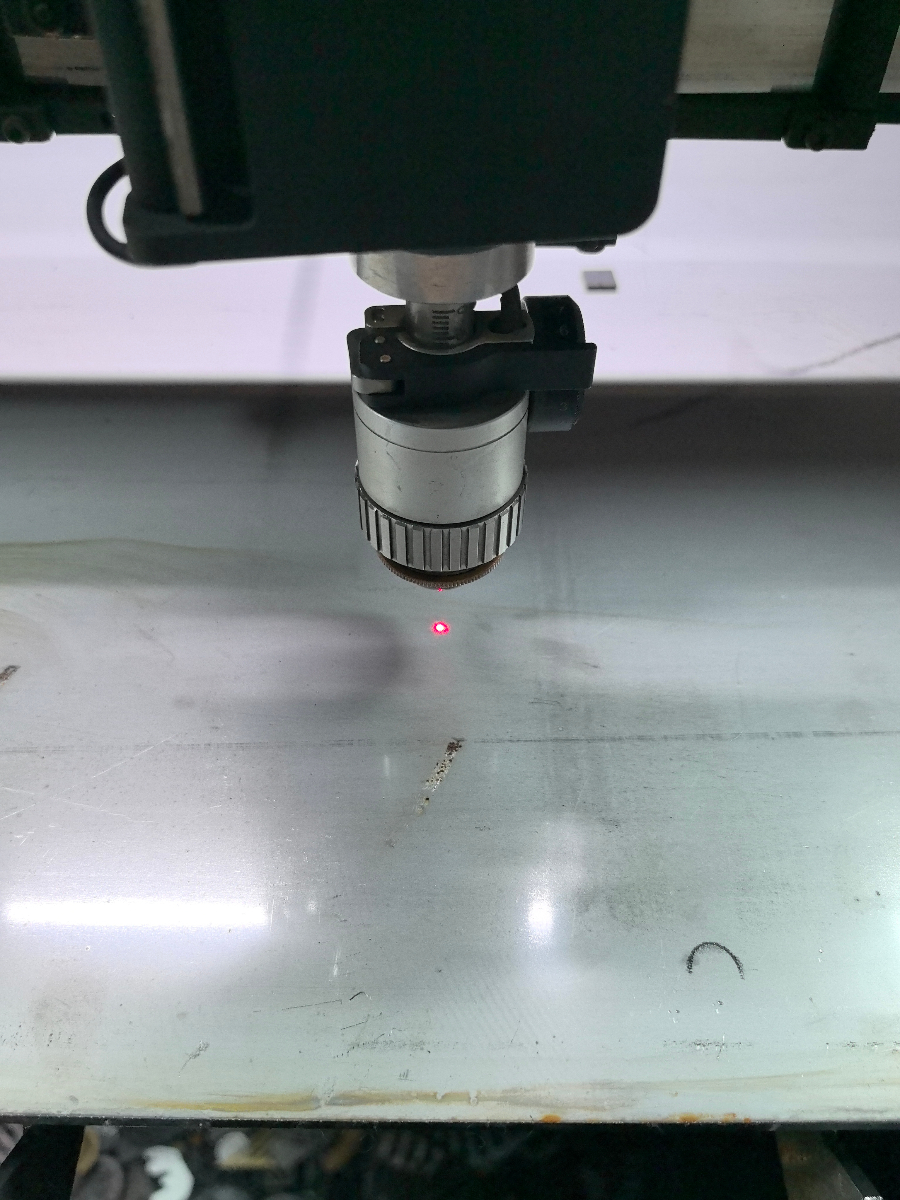

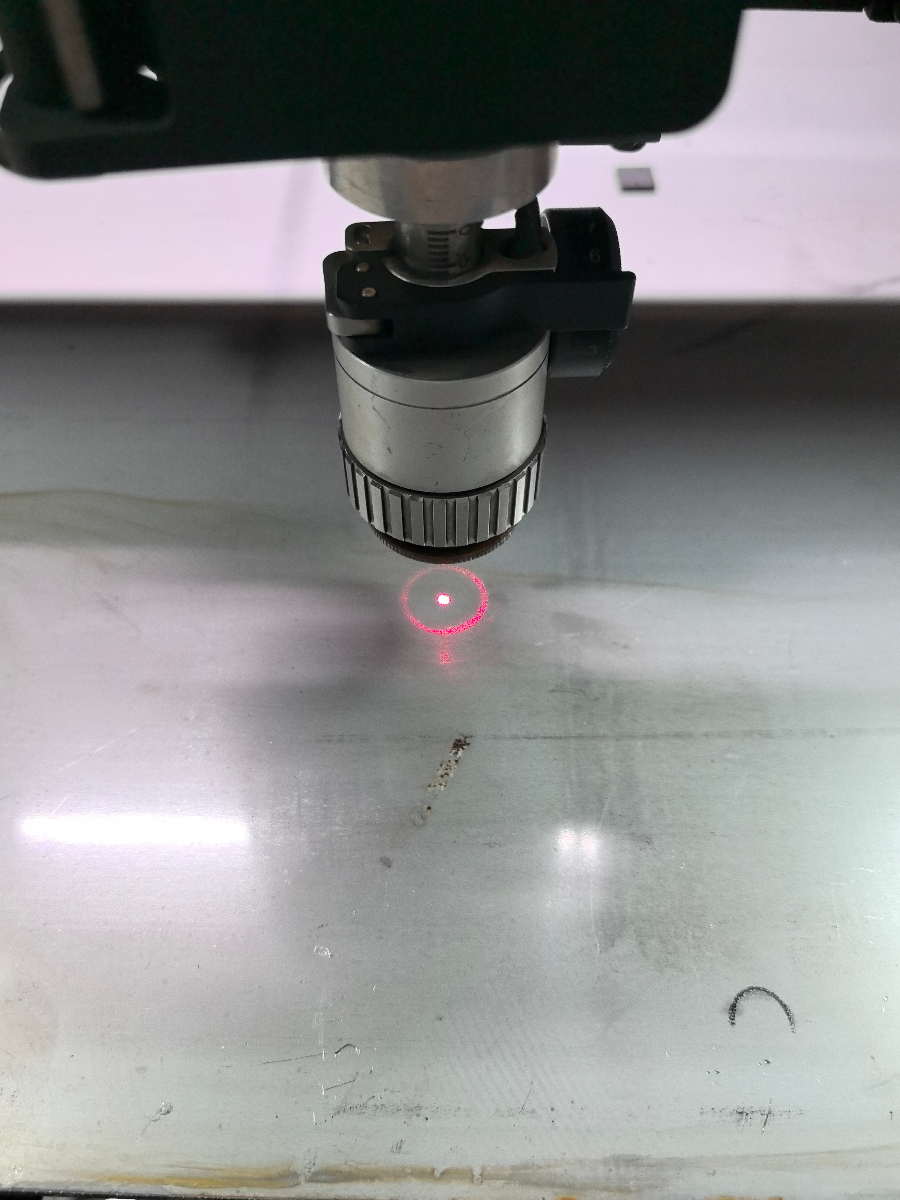

Q4: How to distinguish whether the lens inside the welding head is a cleaning lens or a lens protector for welding?

A: Please follow the steps below to identify and take the correct action:

- Post-Cleaning Action: After using and dismantling the MaxClean Accessory, promptly replace the cleaning lens with a lens protector.

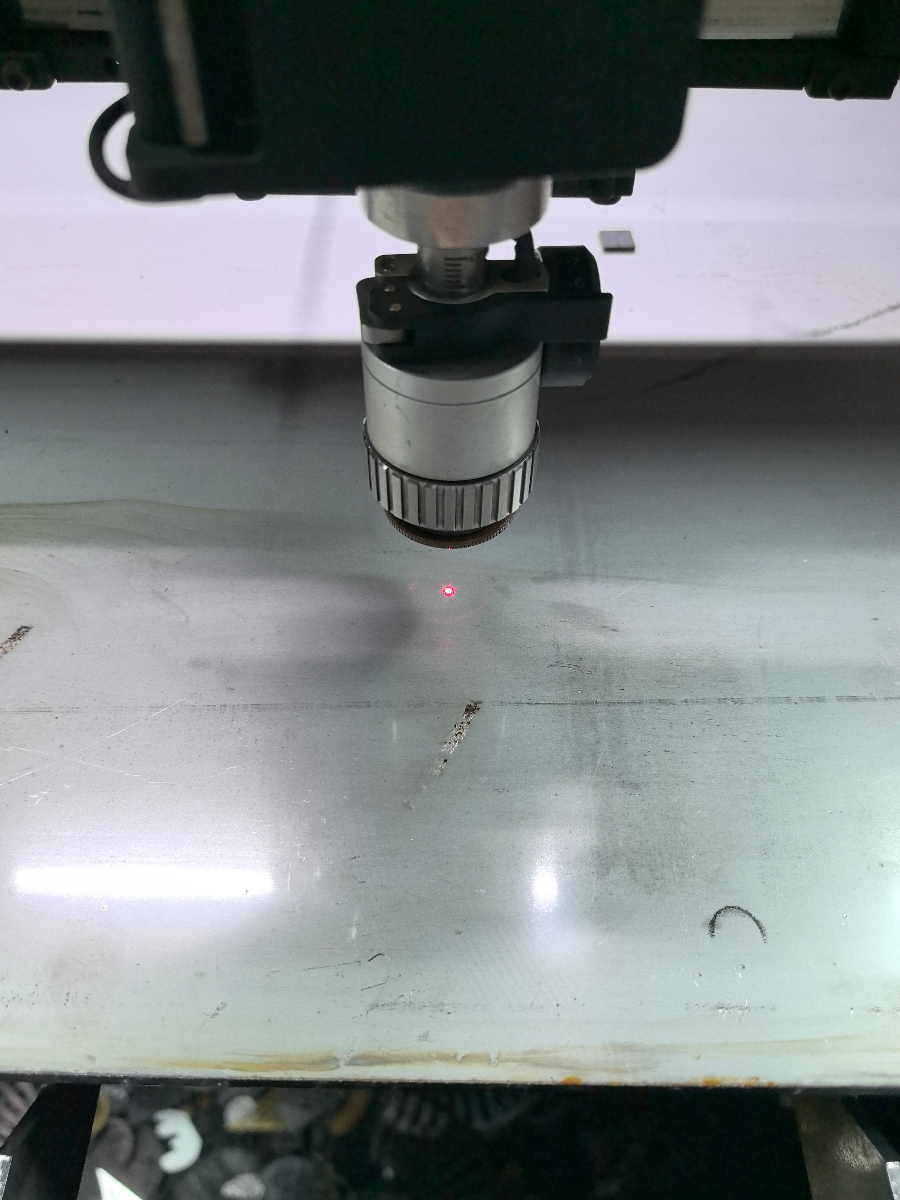

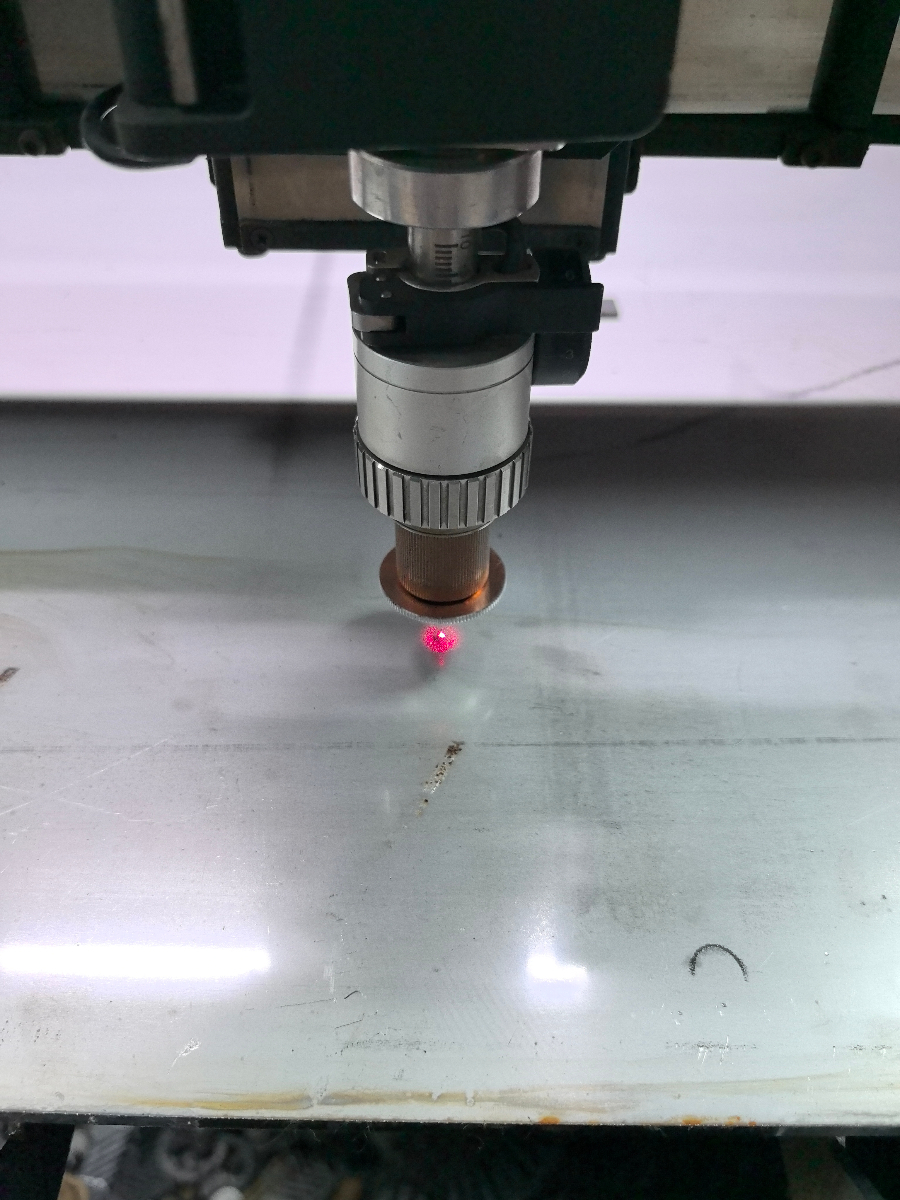

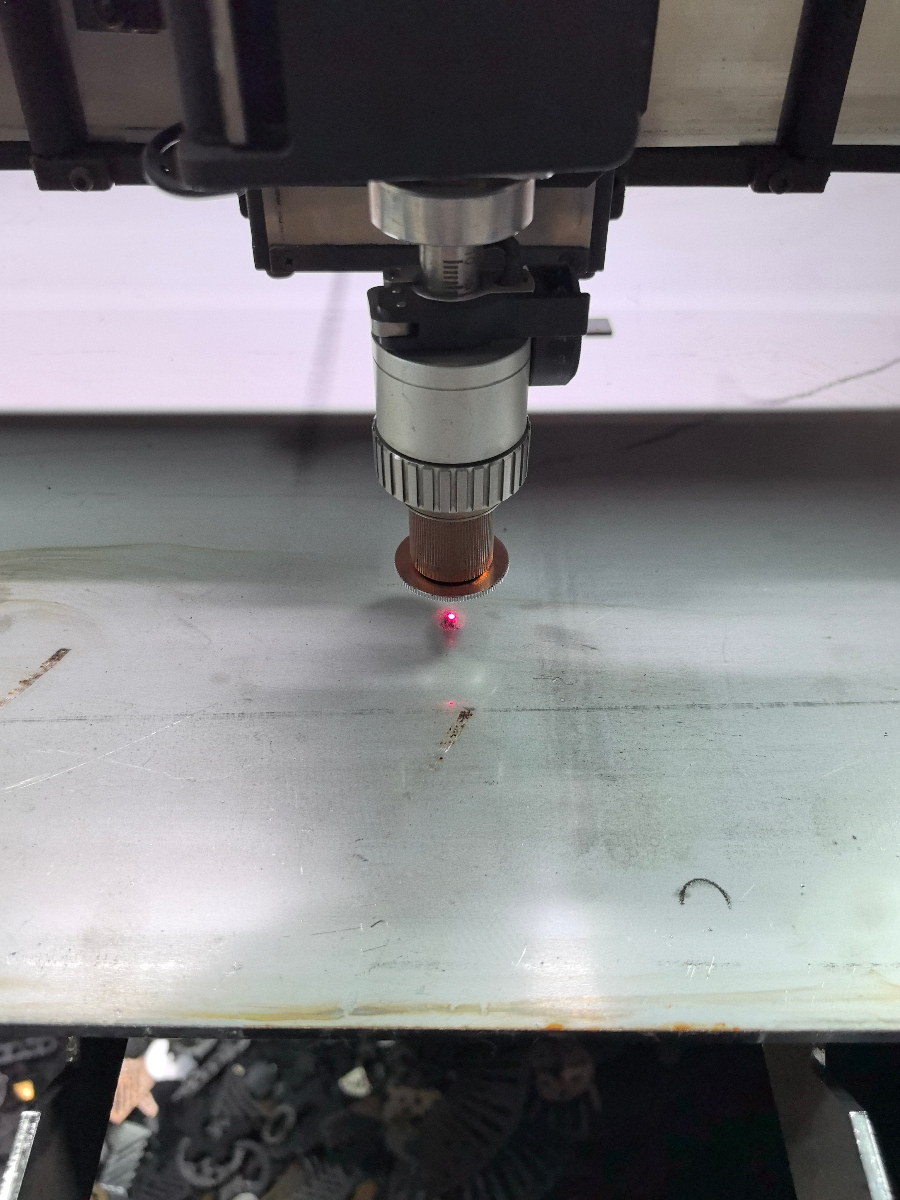

- Pre-Welding/Cutting Check: Before starting any welding or cutting operation, check the red spot emitted from the welding head: if it appears large and blurry, a cleaning lens may have been mistakenly installed. Replace it with a lens protector.

Warning: If a cleaning lens is used for welding or cutting (especially CNC cutting), there may be a risk of equipment damage. Therefore, after using the MaxClean Accessory, the lens must be replaced first before using other functions.

Key distinctions:

Spot shape with cleaning lens | Spot shape with lens protector | |

Welding nozzle |

|

|

Telescopic cutting nozzle (SaveGas™ nozzle) (Descending distance: 40 mm) |

|

|

2 mm cutting nozzle (for CNC use) (Descending distance: 40 mm) |

|

|

1 mm double-layer nozzle + extension tube (Descending distance: 30 mm) |

|

|

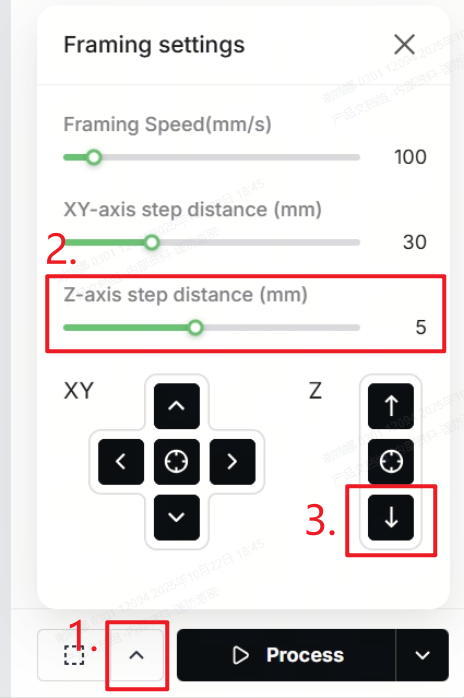

How to set the descending distance?

- In xTool software, click Framing settings.

- Set Z-axis step distance to 10 mm.

- To move the welding head down by 30 mm, click the down arrow 3 times. (To descend 40 mm, click the down arrow 4 times.)

Operation & processing tips

Q1: Do I need a license or certification to operate MetalFab Laser Welder?

A: No additional certification is required. However, we strongly recommend users complete our basic safety training about laser welding operations to ensure using the machine safely.

Q2: Is prior welding experience required?

A: No. The machine is beginner-friendly and easy to operate.

Q3: Can xTool MetalFab Laser Welder be used in wet environments or underwater?

A: Yes, but immerse only the copper nozzle of the welding head can be submerged. Keep the rest of the welding head dry, as it is not waterproof.

Q4: Can xTool MetalFab Laser Welder be used for marking or engraving?

A: Yes, it can. But it is not recommended to mark or engrave on highly reflective materials. Metal materials are often highly reflective, especially brass and aluminium. They can reflect laser beams and cause permanent damage to the machine.

You are recommended to mark or engrave on materials like stainless steel, carbon steel, and galvanized sheet, which do not reflect too much light. For a detailed list of the supported materials, please refer to Materials Supported by xTool MetalFab.

Q5: Can xTool MetalFab Laser Welder detect defects like cracks in real time during welding?

A: No, real-time defect detection is not supported.

Q6: What shielding gas should I use, and what’s the recommended flow rate?

Supported gas type:

- Nitrogen (gas purity ≥ 99.99%)

- Argon (gas purity ≥ 99.99%)

- Compressed air

Processing mode | Gas setting | Notes |

|---|---|---|

Laser Welding | Flow rate: 15 L/min – 30 L/min Pressure: 0.1 MPa – 0.2 MPa |

|

Laser Cleaning | Flow rate: 15 L/min – 30 L/min Pressure: 0.1 MPa – 0.2 MPa | |

Laser Cutting | Gas pressure: 600 kPa – 800 kPa |

Q7: How do I set the Scan width for the welding head?

A: Set the Scan width based on material characteristics and joint requirements:

- Material Properties

- High thermal conductivity (Aluminum, Copper): Use wider oscillation (typically 1.0-2.0mm) to distribute heat and prevent localized overheating

- Low thermal conductivity (Stainless Steel): Narrower oscillation (0.3-0.8mm recommended) concentrates energy for proper penetration

- Joint Gap Requirements

- Narrow joints (<0.5mm gap): Small scan width (0.5-1.0mm) maintains focused energy density

- Wide joints (>1.0mm gap): Wider oscillation (1.5-3.0mm) ensures full coverage and uniform fusion

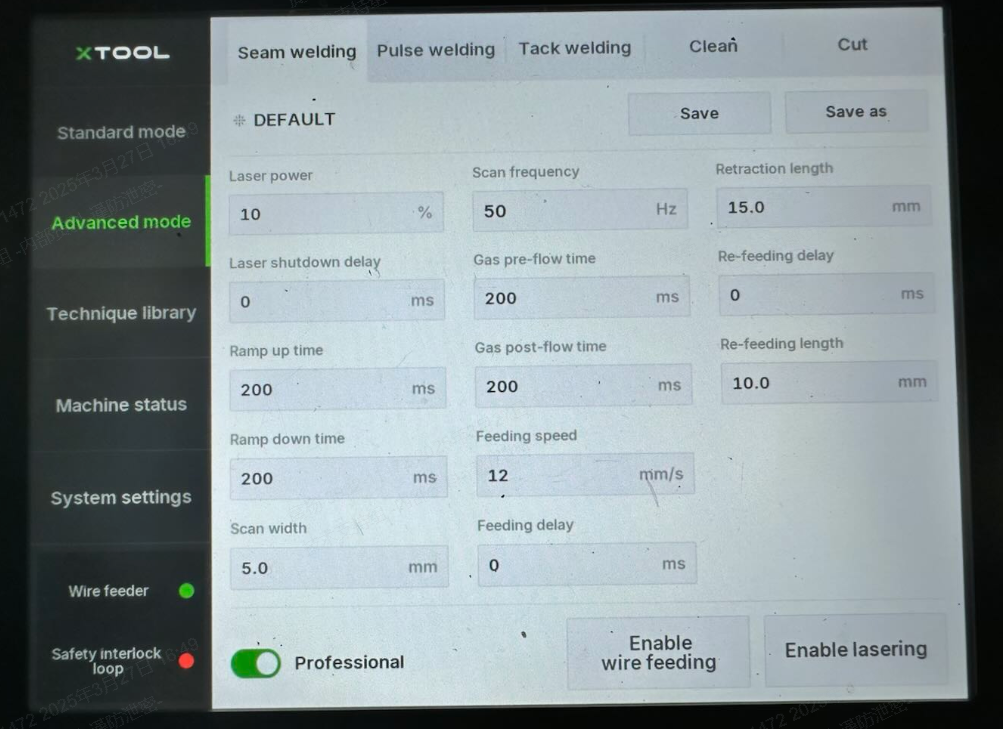

Q8: What should I do if filler wire sticks during welding?

To resolve filler wire adhesion, you can:

- Increase the laser shutdown delay time;

- Or decrease the Re-feeding delay.

Q9: Why does black smoke appear during welding?

A: Black smoke during welding can result from several factors:

- Material Properties: Some materials—especially aluminum alloys—are more prone to generating smoke due to their sensitivity and composition.

- Surface Contamination: Oil films, grease, or oxide layers on the material's surface can increase smoke production during welding.

- Welding Wire: Standard welding wires not designed for laser welding may produce more fumes. Low-fume wires are recommended for cleaner welds.

- Welding Technique: Incorrect torch angles, inadequate shielding gas flow rates, or improper power settings can lead to incomplete gas coverage, leading to more smoke.

- Damaged Lens: A damaged lens can scatter the laser beam or arc energy, increasing smoke and reducing overall weld quality.

Q10: Can I manually fine-tune welding parameters?

A: Yes, xTool MetalFab Laser Welder 1200W allows users to manually fine-tune welding parameters. For more control, switch to Advanced Mode and enable the Professional option to customize settings according to your specific requirements.

Q11: Will continuous use cause laser power to drop due to overheating?

A: No, xTool MetalFab Laser Welder 1200W is designed to maintain stable power output for extended periods under normal operating conditions. Power degradation will not occur during processing.

Q12: Does Metalfab Laser Welder support remote diagnostics and fault alerts?

A: No, these features are not supported.

Q13: Can I import design files like SVG or DXF?

A: No. This is a handheld tool with its own operating system and does not support external file imports.

Q14: Can Metalfab Laser Welder export logs or processing data?

A: No, the machine does not support data export.

Welding different materials

Q1: What materials can the welder process? What is the thickness?

Material | Maximum thickness | Remarks |

|---|---|---|

Stainless steel | 5 mm | The maximum thickness refers to the maximum depth that can be fully penetrated (welded through). It does not mean that only sheets of this thickness can be welded. |

Carbon steel | 5 mm | |

Galvanized steel | 5 mm | |

Aluminum | 4 mm | |

Brass | 3 mm |

Q2: Is laser welding as strong as traditional arc welding (TIG/MIG)?

A: Laser welding typically matches or exceeds the strength of traditional TIG or MIG methods. It creates a smaller heat-affected zone, produces deeper and narrower welds, and forms finer-structured seams. These characteristics result in superior performance and structural integrity compared to conventional welding techniques.

Q3: How can I find the best settings for welding materials of different thicknesses?

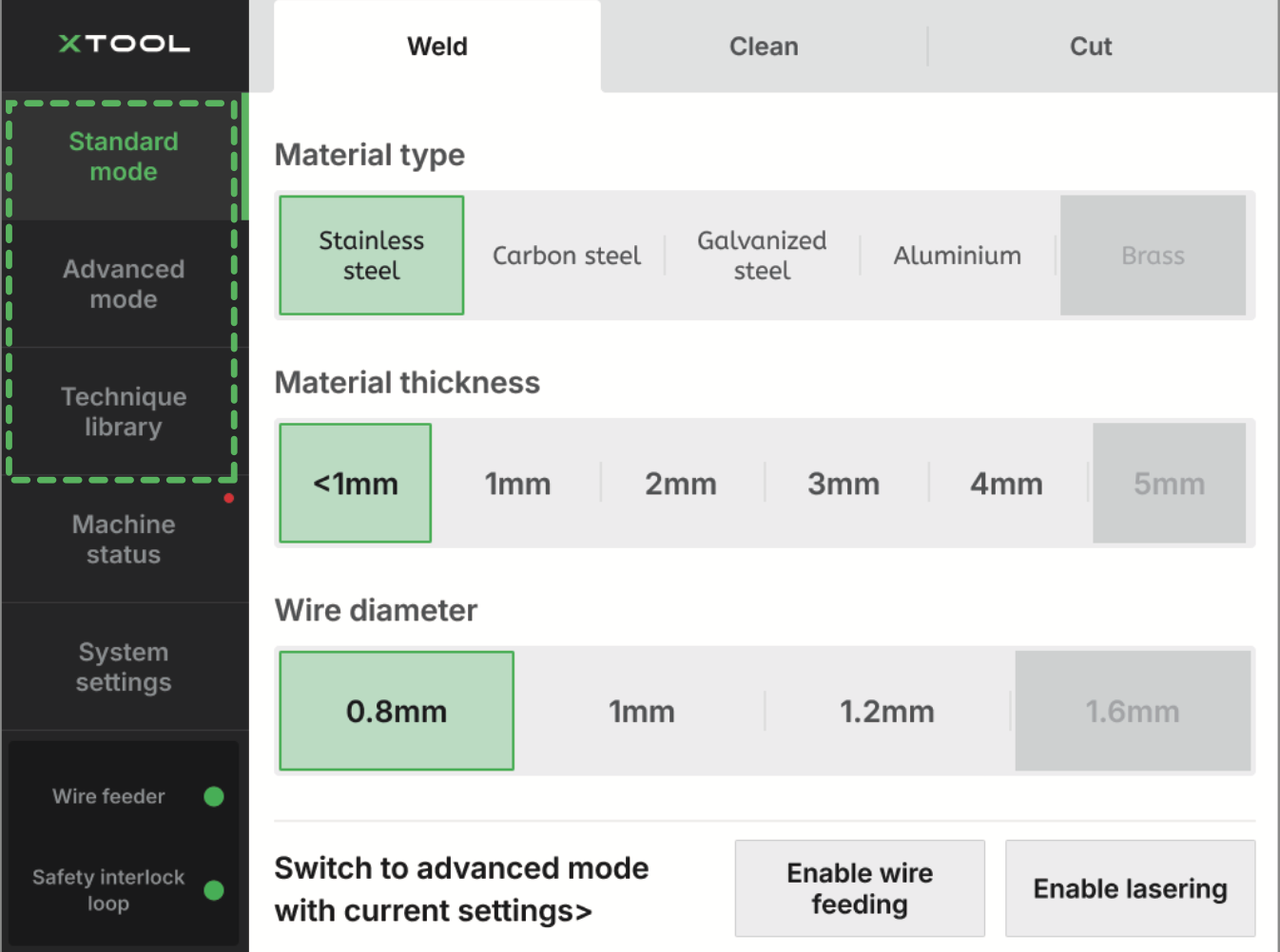

A: xTool MetalFab Laser Welder 1200w defaults to Standard mode upon startup. In this mode, users can simply select material type, thickness, and wire diameter to begin welding--ideal for quick setup. For more experienced users seeking greater control, switching to Advanced mode unlocks additional parameter settings, allowing fine-tuning based on specific welding needs.

Q4: Can laser welding achieve the same penetration depth as traditional methods when welding 5 mm stainless steel?

A: With appropriate process parameters, xTool MetalFab Laser Welder 1200W can typically achieve a penetration depth of 5mm or even deeper. The specific penetration depth depends on factors such as the set laser power, welding speed, and focal position.

Q5: How can I prevent porosity when laser welding aluminum alloys?

A: To avoid porosity, you should pay attention to these things:

- Material Preparation: Thoroughly clean the aluminum surface to remove oxide layers and contaminants. Ensure the material is completely dry before welding.

- Parameter Settings: Increase wire feed speed as needed to optimize the welding process and prevent gas entrapment.

- Gas Selection: Use argon as the preferred shielding gas for welding aluminum. While nitrogen can be used under normal conditions, argon is more effective in reducing porosity in this application.

Q6: Can xTool MetalFab Laser Welder weld or cut titanium and magnesium alloys?

A: Yes, and you will need argon gas when processing titanium.

Q7: How do I prevent zinc layer evaporation and contamination when welding galvanized steel?

A: To minimize zinc vaporization and contamination during welding, implement these measures:

- Laser power and welding parameters control

- Reduce laser power: Use appropriately lowered power settings

- Optimize welding speed: Maintain proper speed to avoid heat concentration

- Shielding Gas Protection

- Use Argon/Nitrogen: These inert gases prevent oxidation and reduce zinc fumes

- Adjust gas flow: Ensure sufficient, stable coverage of the weld zone

- Zinc Layer Pre-treatment

- Local zinc removal: Mechanically grind or chemically strip zinc from weld areas

- Laser ablation: Pre-clean with low-power laser to remove zinc coating

- Ventilation & Safety

- Install fume extraction: Effectively remove hazardous zinc oxide particles

- Wear proper PPE:

- Respiratory protection (NIOSH-approved masks)

- Laser safety goggles

Upgrades & integration

Q1: Can I upgrade the laser power or firmware? What are the costs?

A: MetalFab Laser Welder's laser power cannot be increased, but you can freely update the firmware using xTool Creative Space (XCS).

Q2: Can I use Metalfab Laser Welder on the same circuit as other welding machines?

A: To ensure safety and prevent electrical overload, we recommend operating this laser welder on a separate circuit from other welding equipment.

Q3: Does MetalFab Laser Welder support multi-axis synchronization, such as with robots?

A: Currently, MetalFab Laser Welder 1200W only supports MetalFab CNC Cutter, and is not compatible with third-party multi-axis systems.

Q4: Will future versions support multiple laser heads working together?

A: No, there are currently no plans to support this feature.

Security

Q1: Is MetalFab Laser Welder safe to use?

A: MetalFab Laser Welder includes multiple safety features such as a safety circuit loop, USB key lock, emergency stop button, and the Grip sensing button on the welding head to ensure safe and controlled operation.

Q2: Is MetalFab Laser Welder environmentally compliant?

A: Yes. It meets all required certifications and offers greater environmental benefits than traditional welding due to its cleaner laser process.

Q3: Does MetalFab Laser Welder exceed typical industrial noise levels?

A: When operating at full power, MetalFab Laser Welder generates noise levels above 90 dB, which exceeds standard industrial thresholds. Prolonged exposure at this level may affect hearing, so we strongly recommend wearing hearing protection during operation.

Q4: Is the emergency stop mechanism reliable?

A: xTool MetalFab Laser Welder 1200W features a certified emergency stop button. Once pressed, it immediately cuts off power to the laser for enhanced operational safety.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.