Wire feeding structure

Specifications of the wire feeding system

Wire feeding speed | 2 mm/s to 100 mm/s |

Maximum wire spool weight supported | 5 kg |

Maximum external diameter of wire spool supported | 200 mm |

Maximum thickness of wire spool supported | 60 mm |

Supported wire diameters | 0.8 mm, 1.0 mm, 1.2 mm, 1.6 mm |

Length of the wire feeding tube | 3 m |

Install wire feeding accessories

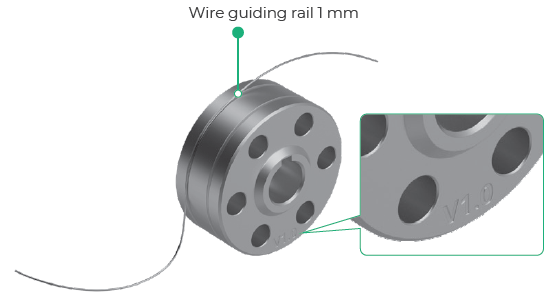

Note: ■ Only wire-filled welding requires the use of welding wire. Other scenarios (including autogenous welding, laser cleaning, and laser cutting) do not use welding wire. ■ This guide exemplifies installing 1 mm welding wire (provided) on the 1 mm guiding rail. |

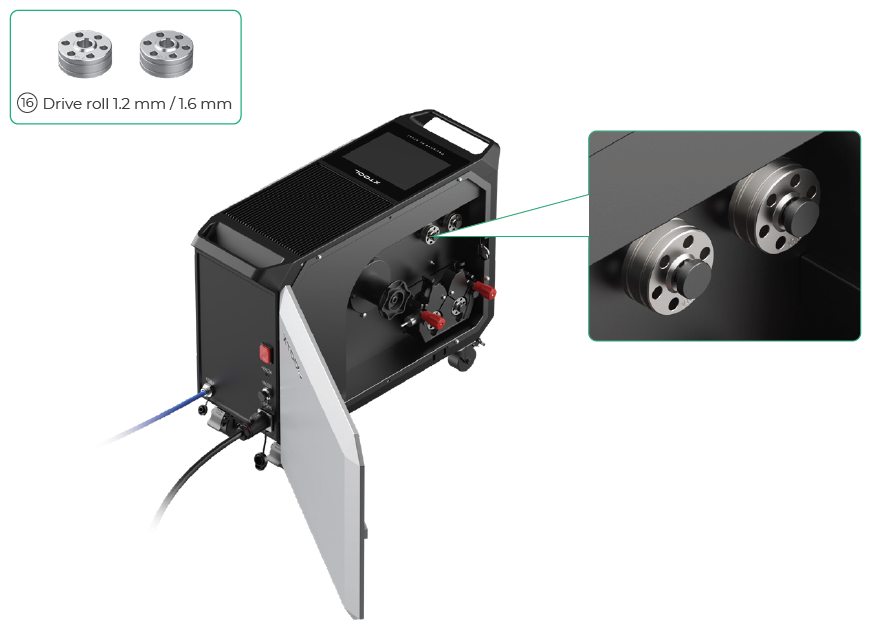

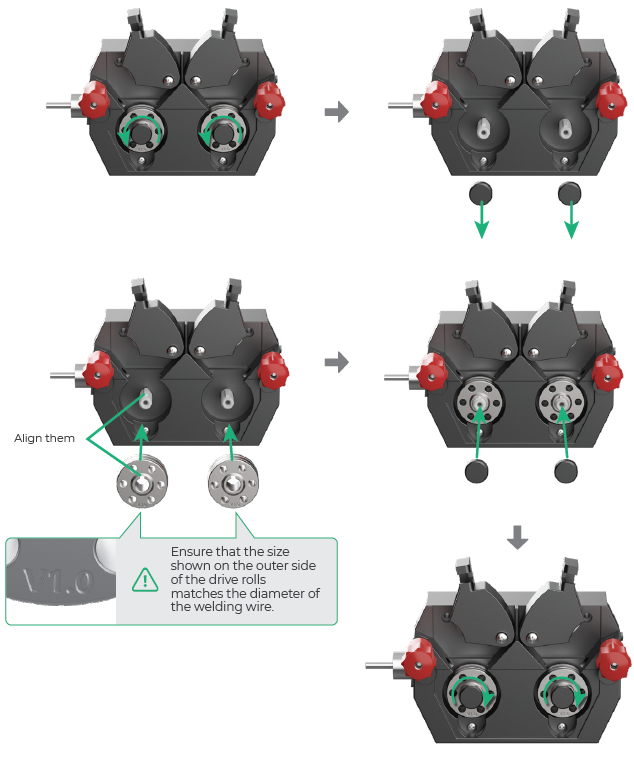

1. Install the drive rolls

Tips: How to check the specifications of the drive roll Each drive roll has two rails, and the size of each rail is marked on the cross-section that is not adjacent to the rail. When the drive roll is installed on the wire feeding driver, its inner rail is used to guide wire, while its outer side shows the rail size.

Determine the specifications of drive rolls based on the diameter of the welding wire to be used. |

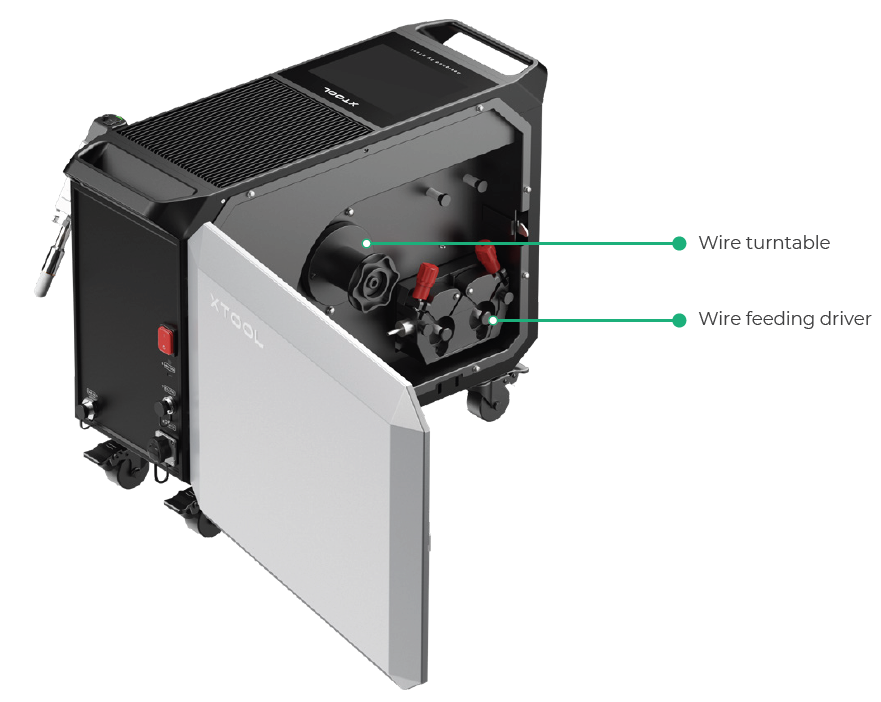

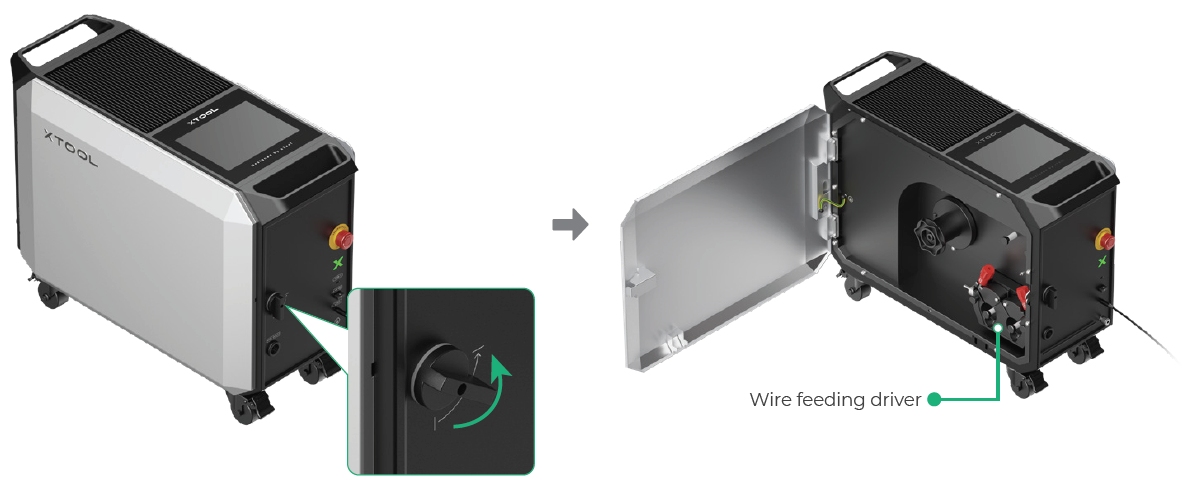

(1) Open the door.

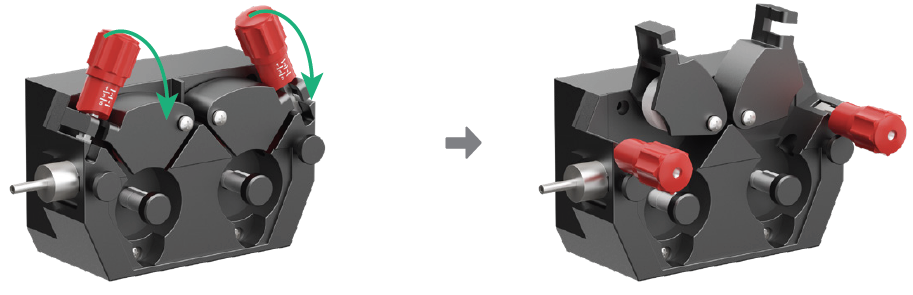

(2) Open the wire feeding driver.

(3) Install the drive rolls.

Tips: The other pair of drive rolls supplied with this product can be stored in the wire feeder for replacement.

|

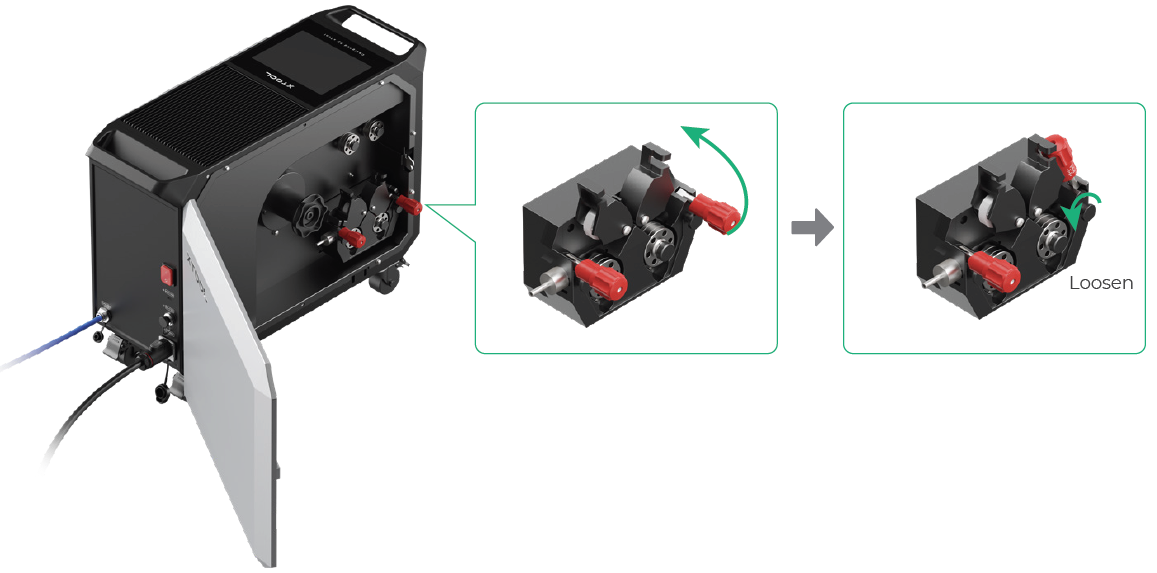

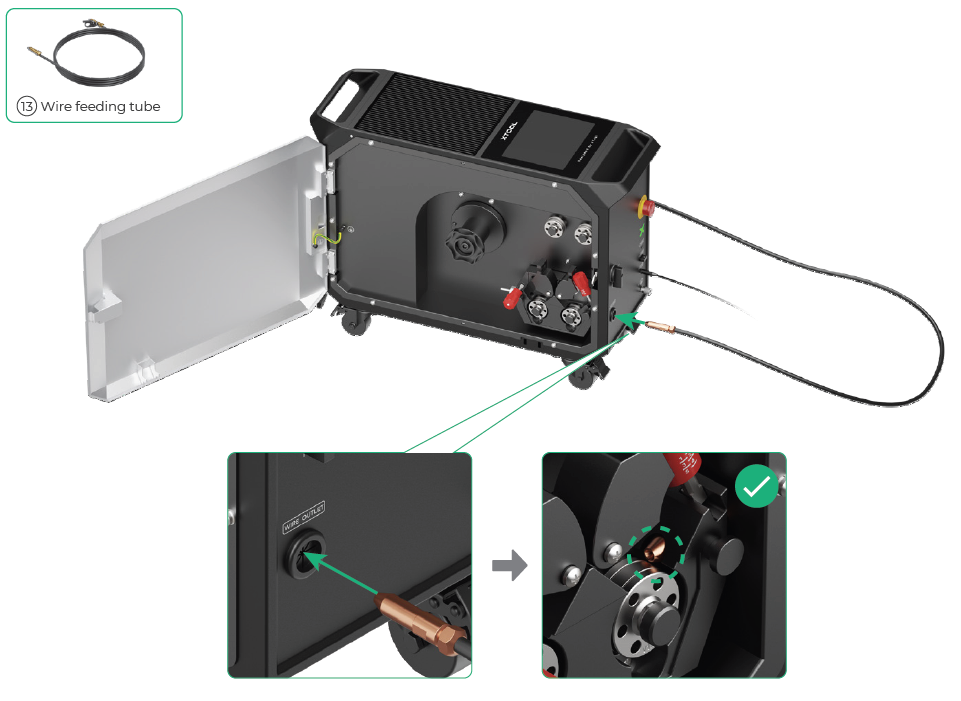

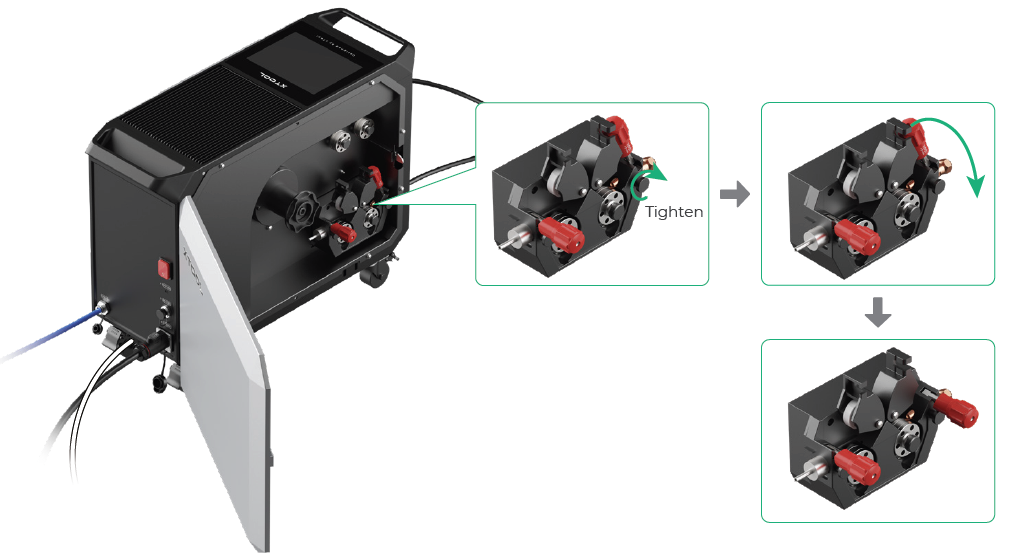

2. Install the wire feeding tube on the main unit

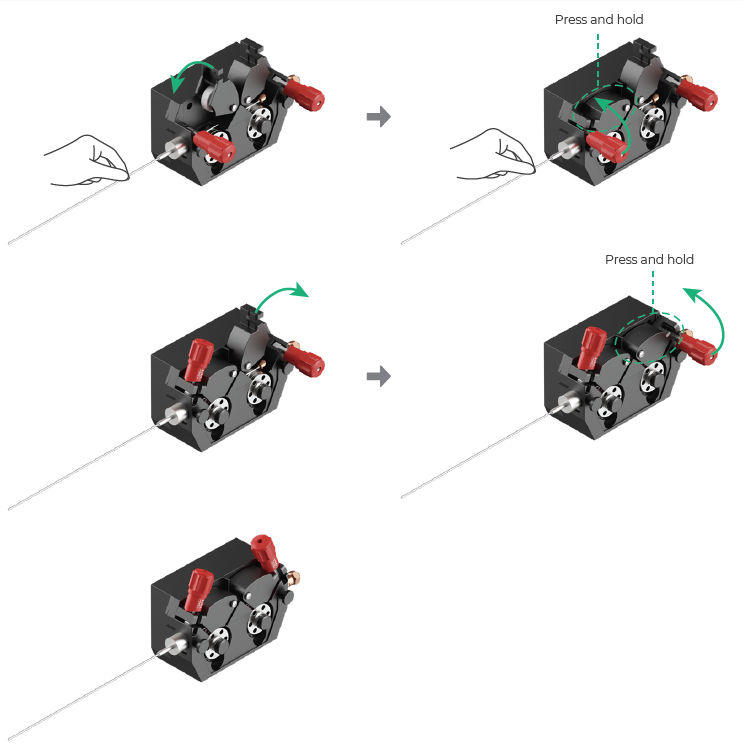

(1) Close the right tensioner, and loosen the screw on the right side of the wire feeding driver.

(2) Insert the end of the wire feeding tube without a fastener to the main unit. Ensure that the wire feeding nozzle shows up at the upper right side of the drive roll.

(3) Tighten the screw to fix the nozzle. Then, open the right tensioner.

3. Load the welding wire

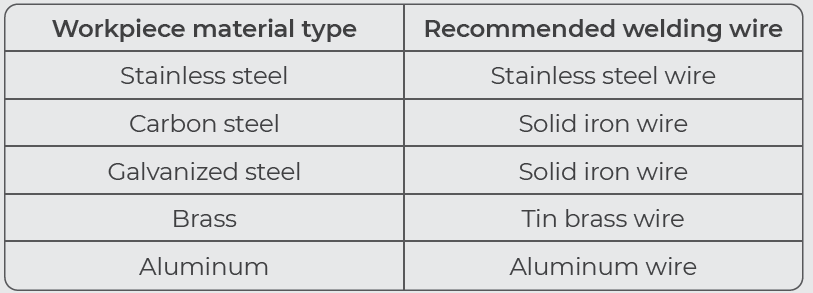

Tips: Select a proper wire Refer to the following table to select a proper wire based on the material type of the workpiece to be welded.

A roll of 1 mm stainless steel wire is included with this product. Use it as needed. Caution: For aluminum welding, use wire thicker than 1.0 mm. Thinner wires (0.8 or 1.0 mm) are too soft and may cause clogging. |

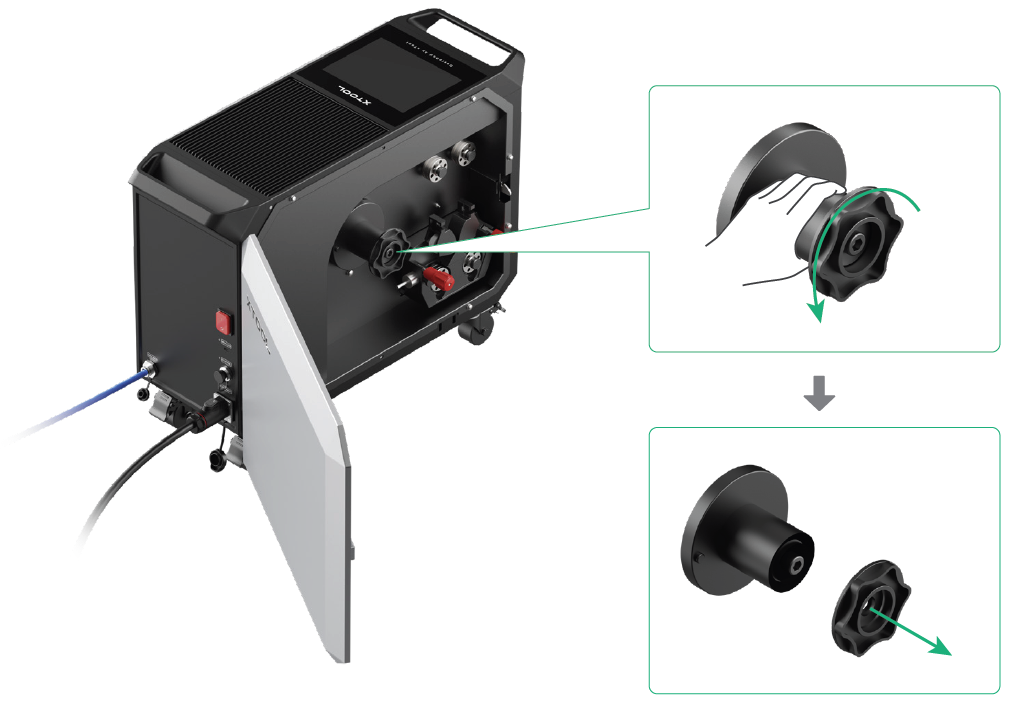

(1) Unscrew the cap of the wire turntable.

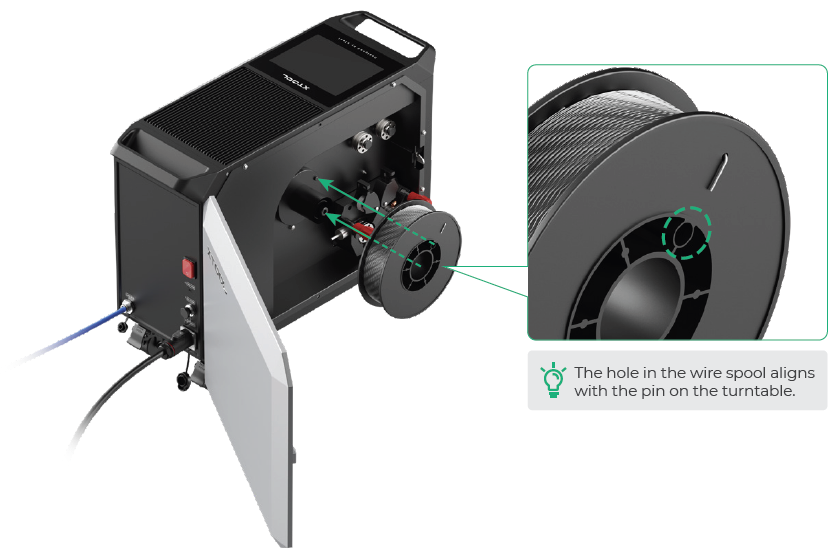

(2) Install the wire spool to the turntable.

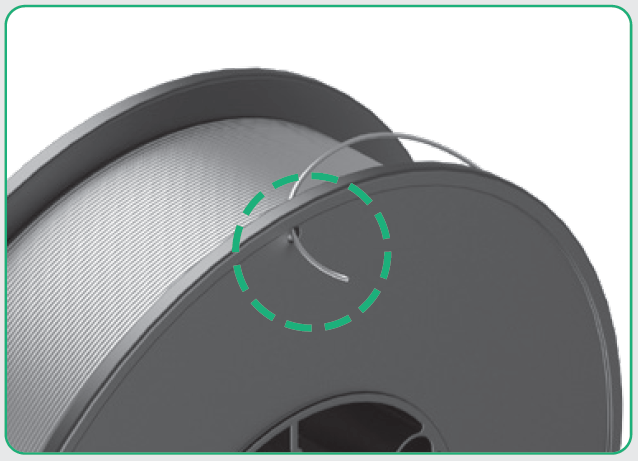

Caution: ■ When installing the wire spool, keep the end of the wire fixed. Do not release the wire yet, as it may unravel and become unusable.

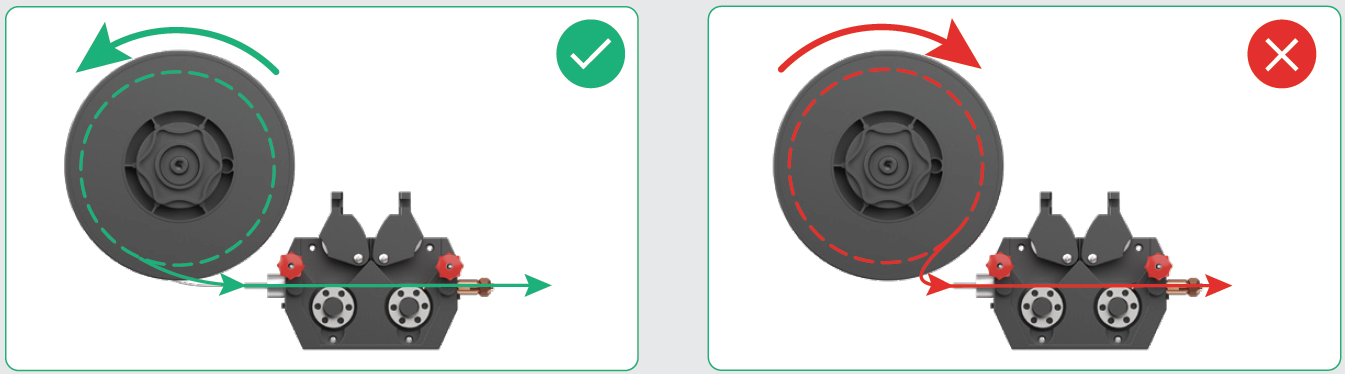

■ Ensure that the wire spool is installed in the correct direction. After released, the wire comes out from the bottom of the wire spool to enter the wire feeding driver. During wire feeding, the wire spool rotates counterclockwise.

|

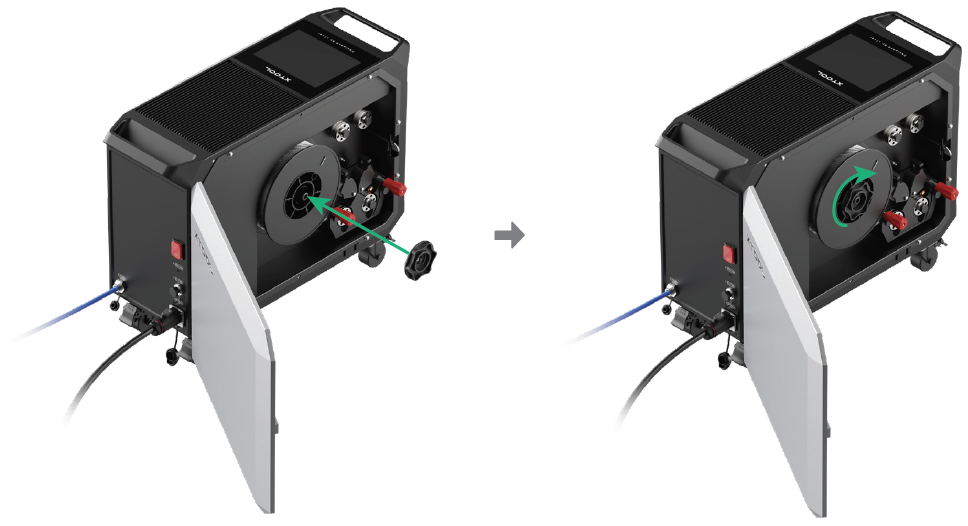

(3) Screw the cap back.

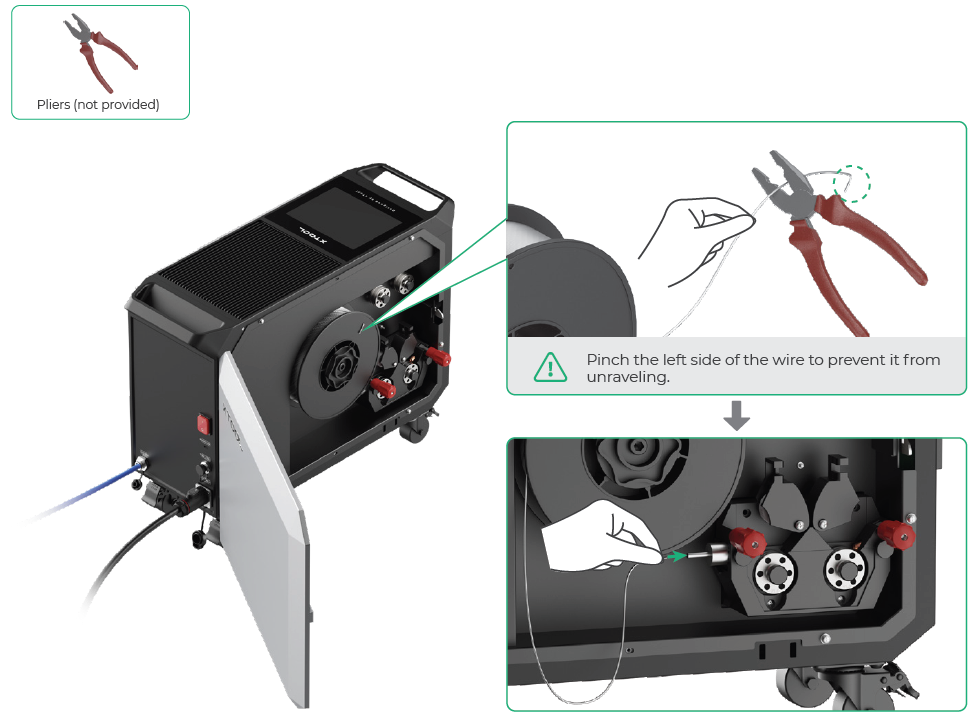

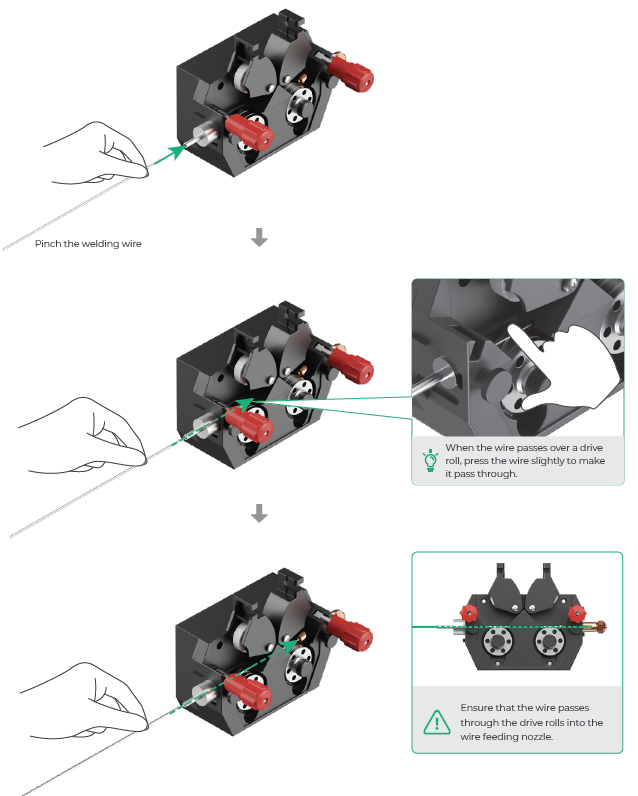

(4) Take out the wire end, cut off the bent part, and thread the wire into the wire feeding driver.

Caution: When inserting the wire, pinch the wire to prevent it from moving backward and unraveling. |

Caution: Pinch the wire until you close a tensioner. |

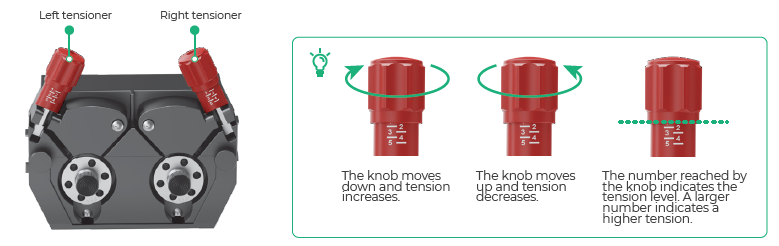

(5) Rotate the tensioners' knobs to adjust the wire feed tension.

Adjust the roller tensioners based on the wire diameter by referring to the table below. Then, fine-tune the tension according to the actual situation.

Welding wire diameter (mm) | Left tension level | Right tension level |

0.8 | 2.5 | 2 |

1 | 2.5 | 2 |

1.2 | 2 | 1.5 |

1.6 | 2.5 | 2 |

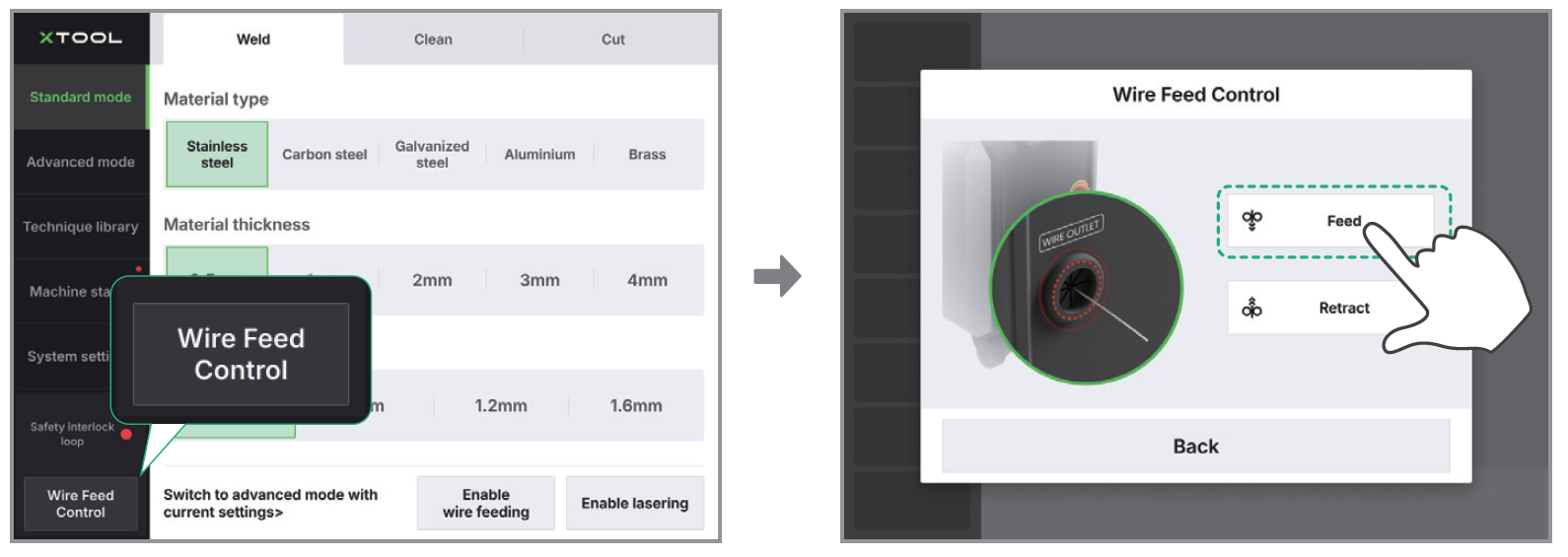

4. Feed the welding wire

Note: To feed wire electrically, ensure that the main unit is turned on. |

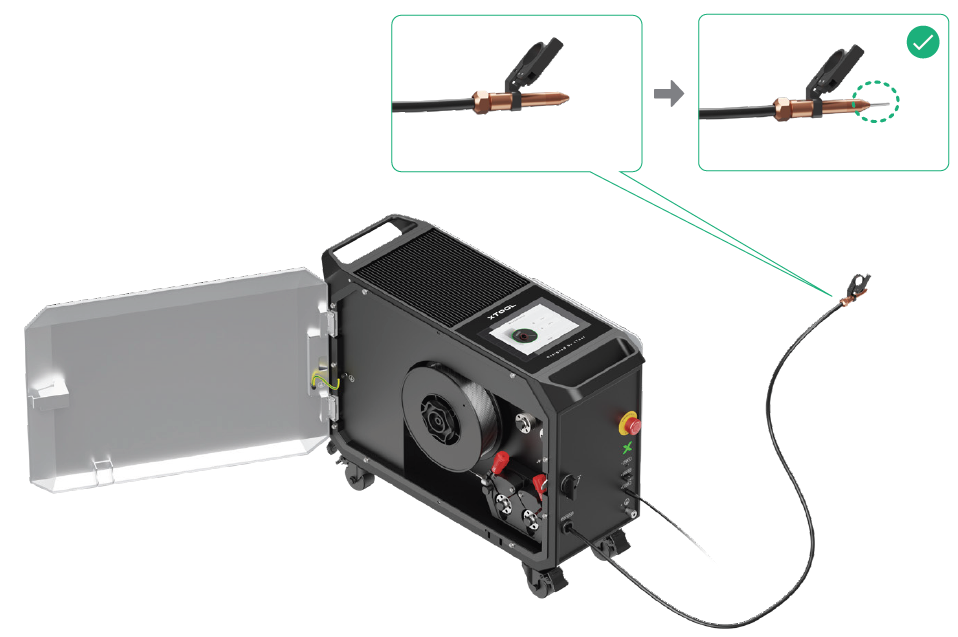

(1) Based on the table below, check if the wire feeding nozzle is of the right size to feed the wire you use.

Wire feeding nozzle | Supported wire diameter |

| 0.8 mm / 1.0 mm |

| 1.2 mm / 1.6 mm |

Note: When delivered, the wire feeding tube is installed with a 0.8 mm / 1.0 mm nozzle at the end with a fastener, and can feed either 0.8 mm or 1.0 mm wire. If you use a 1.2 mm or 1.6 mm wire, please replace the 0.8 mm / 1.0 mm nozzle with the provided 1.2 mm / 1.6 mm wire feeding nozzle. For more replacement instructions, see Replace the Wire Feeding Nozzle for xTool MetalFab Laser Welder. |

(2) On the touchscreen, tap Wire Feed Control. Press and hold the Feed button until the wire extends out of the nozzle.

Caution: When feeding the wire, observe the inside of the wire feeder. If the wire spool rotates counterclockwise at a constant speed, the wire feeder is working properly. |

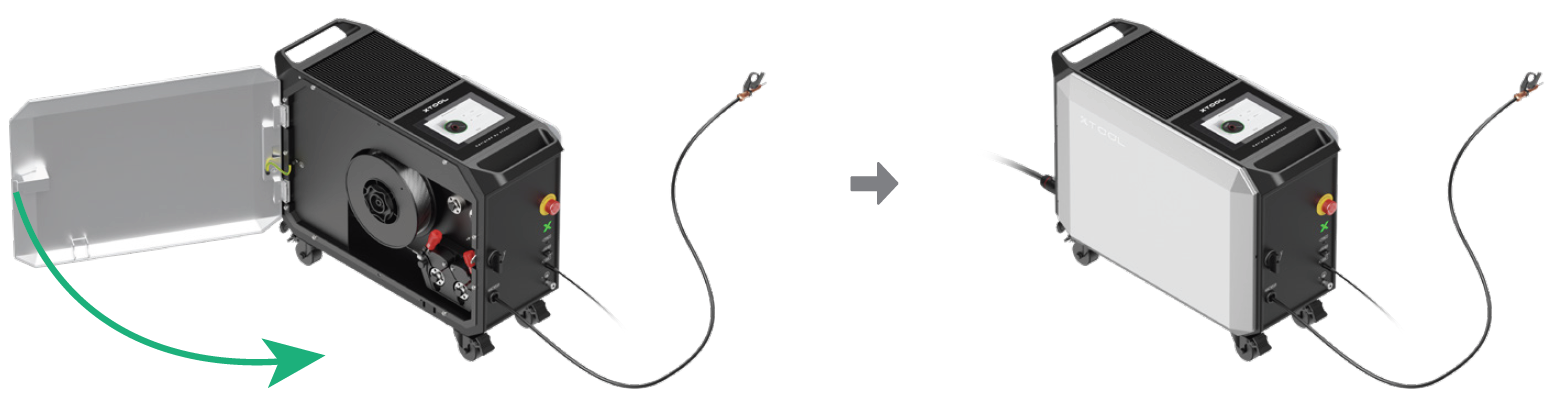

(3) Close the door.

5. Install the wire feeding tube on the welding head

Caution: To prevent accidentally triggering laser emission, ensure that Enable lasering is off on the touchscreen before operations. |

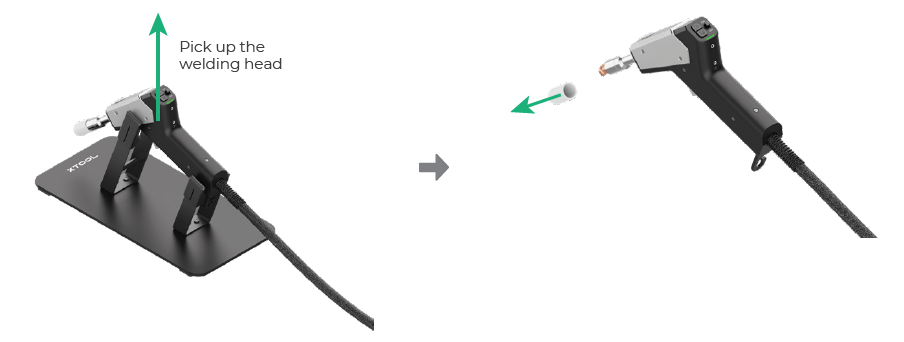

(1) Pick up the welding head and remove the dustproof cap.

Caution: Keep the dustproof cap properly. When you are not using the welding head, cover the welding tip with the cap to prevent dust from getting inside and damaging the welding head. |

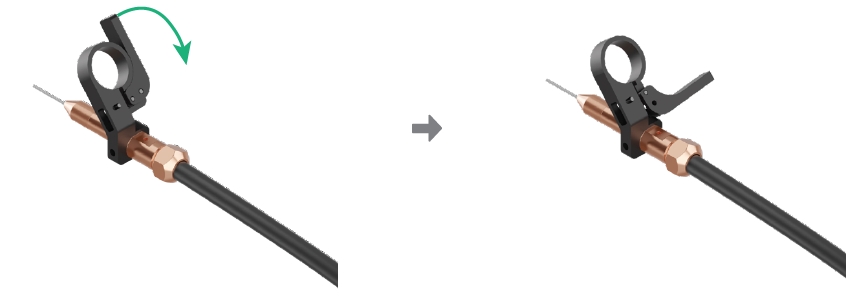

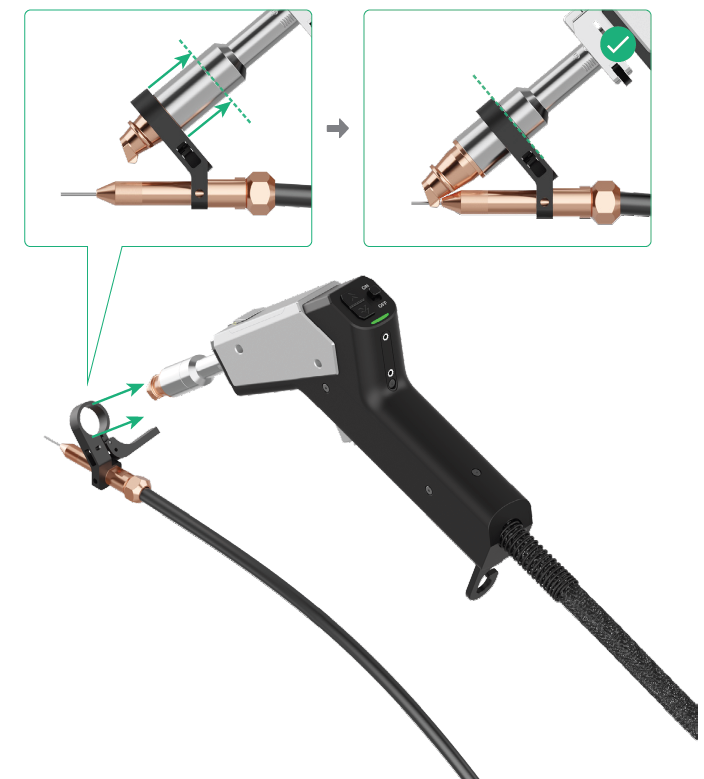

(2) Open the fastener on the wire feeding tube.

(3) Slide the fastener onto the welding head until the ring reaches the marking line. (You can further fine tune its position as needed.)

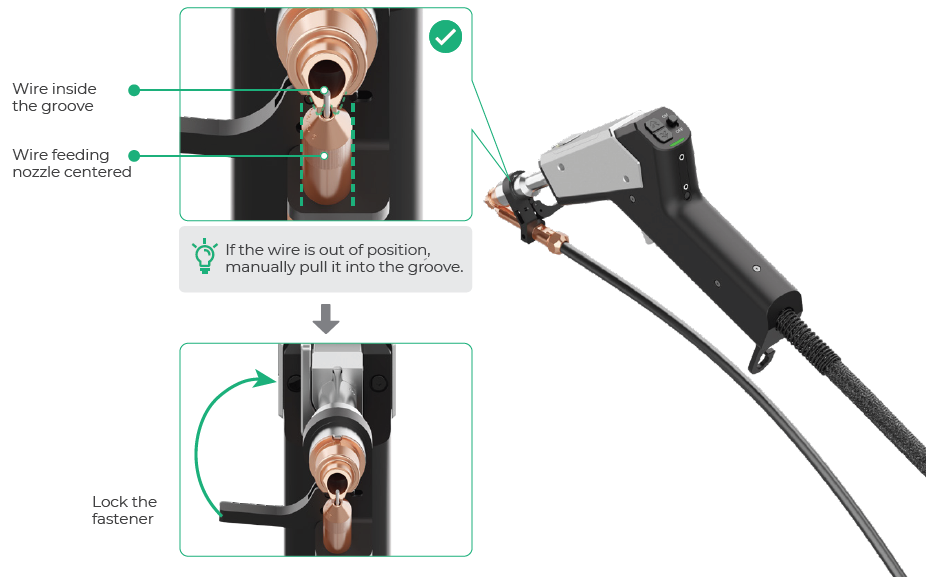

(4) Ensure that the wire feeding nozzle is centered and that the wire comes out from the groove of the welding nozzle. Then, lock the fastener.

(5) Secure the wire feeding tube in the wire clamp of the welding head. Then, place the welding head back to the cradle.

Replacement & maintenance

For instructions on part replacement for the wire feeding system, refer to the following documents:

- Replace the Welding Wire for xTool MetalFab Laser Welder

- Replace the Wire Feeding Nozzle for xTool MetalFab Laser Welder

If you encounter any exceptions related to welding wire, refer to the following documents for troubleshooting:

- Troubleshoot Wire Feeding Failure for xTool MetalFab Laser Welder

- Troubleshoot Erratic Wire Feeding for xTool MetalFab Laser Welder

- Troubleshoot Improper Wire Melting and Filling for xTool MetalFab Laser Welder

Note: For more information on how to use the laser welder, see Support for xTool MetalFab Laser Welder. |

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.