Read and get familiar with all safety precautions and procedures before using the machine. When the machine is turned on, carefully read the safety instructions displayed on the touchscreen. Strictly follow all safety precautions. Ensure that the machine is properly assembled and is working properly.

1. Laser safety

Lasers are categorized into several different classes depending on the extent of the potential hazard associated with the laser, with Class 1 being the least dangerous and Class 4 the most dangerous. The United States Food and Drug Administration has indicated that Class 4 lasers may pose an “immediate skin hazard and eye hazard from exposure to either the direct or reflected beam; may also present a fire hazard.”

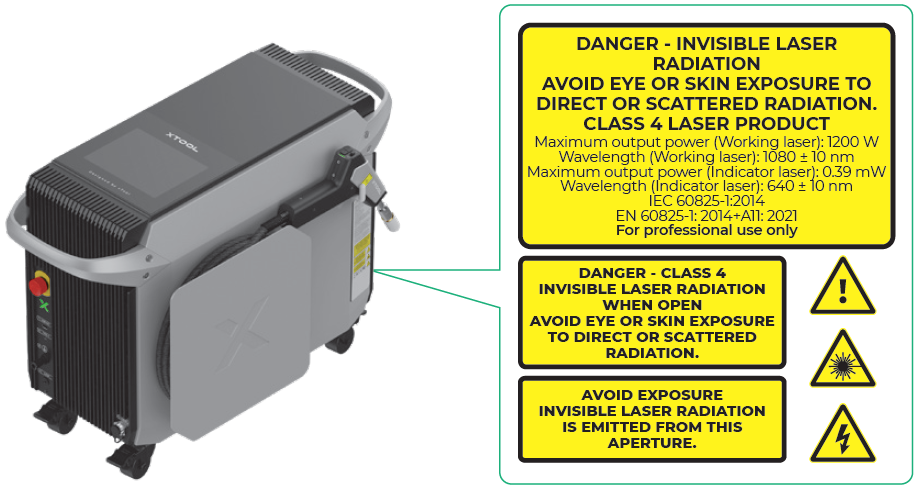

The product is classified as a Class 4 laser machine. It includes a Class 4 working laser and a Class 1 indicator laser. The working laser emits invisible light at a wavelength of 1080 ± 10 nm with a high power. Direct exposure to this level of light can cause severe eye or skin damage. Reflected or scattered laser radiation can also cause severe retinal and/or corneal damage, resulting in permanent eye damage. Moreover, the interaction between the high-power laser beams and the material being welded may generate ultraviolet light, heat, and sparks, which can also lead to a risk of eye and skin damage. The product is intended for professional use only, and extra care should be taken during use to ensure safe operation.

Follow the safety precautions:

Follow the safety precautions:

■ ONLY personnel who have received professional training in welding and laser safety are allowed to use this product. A qualified Laser Safety Officer (LSO) must be appointed and the product shall be operated by or under the guidance of the LSO. LSO is obliged to evaluate laser safety risks to ensure the safety of operators, and set up safety control mechanisms to prevent untrained persons from entering the laser radiation hazard area.

■ For the first time using this product, please go to s.xtool.com/doc/hj/si to watch the Laser Safety Awareness Training Video and the safety training videos on laser welding. Only after watching the videos can you obtain the unlock code for the product. Ensure that all users watch all the videos before using the product. You shall also visit support.xtool.com/article/1171 to read the LSO training documentation for this product and understand the uses and potential hazards of Class 4 lasers. In the workplace, you shall also receive adequate safety training on Class 4 laser products as set forth in ANSI Z136.1 and on welding operations as set forth in ANSI Z49.1, which is the responsibility of the employer to provide.

■ Establish a laser controlled area, and use the product only within this area. You can use the remote interlock function of the USB key to establish such an area. For operational instructions, visit support.xtool.com/article/1367.

■ Only professionally trained personnel wearing necessary personal protective equipment (PPE) are allowed to enter the laser controlled area. You can visit support.xtool.com/article/1444 to learn about the Maximum Permissible Exposure (MPE) and Nominal Ocular Hazard Distance (NOHD) of the product, and determine the safety precautions you need to take.

■ All personnel entering the laser controlled area must wear laser safety goggles or a laser safety face shield that provides shielding against laser beams at the wavelength range of 1080 ± 10 nm, with an optical density greater than 6.

■ In the laser controlled area, it is recommended that all personnel wear the following PPE: (1) the specified laser safety goggles, (2) welding helmet with appropriate filters, (3) laser and heat resistant gloves, (4) laser and heat resistant clothing, and (5) laser and heat resistant aprons.

■ Within the laser controlled area, the laser is hazardous when the device is powered on and the access-control key is inserted. Adequate precautions must be taken because the laser may fire at any time.

■ Do not use the product in residential areas, public places, or on other occasions where untrained persons or children are present.

■ Do not operate the product when any part of it is removed. Removing any part may expose the laser system and cause damage to the product.

■ Never look directly into the laser outlet or point the outlet at any body part.

■ You are advised to use xTool materials and recommended parameters for processing. You can visit easyset.xtool.com and choose your device to find applicable xTool materials and the recommended parameter settings. If you are not using xTool materials or parameters recommended by xTool, or if you are not sure whether the material is applicable to your device, please contact our customer service at support@info.xtool.com for help to ensure safe operation and optimal processing results.

■ Do not use this product to process highly reflective and heat-conductive materials, such as copper (pure copper). The processing may fail and may even damage the product due to the following two reasons: (1) highly reflective materials cannot effectively absorb laser energy; (2) high thermal conductivity makes it hard to form a weld pool on the material being welded, resulting in poor welding performance.

■ During laser processing, the operator and nearby personnel must wear the required PPE against laser, including the specified laser safety goggles and a welding helmet with appropriate filters. The laser safety goggles and welding helmet must be able to withstand a specular laser reflection of full power and nominal working distance for a sufficient period of time to avoid injury.

■ If your skin gets burned by laser beams, disinfect the skin with a povidone-iodine solution immediately and apply burn ointment to the wound. If you are severely burned, go to a hospital and see a doctor as soon as possible.

2. Welding safety

The following hazards may exist during the laser welding process:

Secondary radiation hazards

Visible and invisible radiation is generated during the welding process. The interaction between the high-power laser beams and the material being welded may generate plasmas that produce ultraviolet emissions and “blue light”. Exposure to invisible ultraviolet light without proper protection can result in permanent eye damage and a sunburn-like reaction to the skin, and will increase the risk of skin cancer and accelerate skin aging. Even brief exposure to invisible ultraviolet light during welding can result in blurred vision, burning, tearing, eye pain, and irritation (feeling of sand in the eyes). Therefore, for laser welding, you shall wear PPE that protects you from not only the infrared laser beams, but also the secondary radiation hazards.

Heat and sparks

During the welding process, the interaction between the high-power laser beams and the material being welded may generate sparks, posing the risks of eye and skin injury. Laser processing transfers a large amount of energy to the welded material, making it extremely hot. Thermal radiation and hot particles may also be generated. Contact with a hot surface or exposure to thermal radiation or hot particles may cause severe skin burns. Even after the welding process is complete, some parts of the welding head and the welded material can remain hot for a while. Ensure that proper PPE is used to prevent potential burns.

Laser reflection

Highly reflective metals such as aluminum may cause laser reflection from the welding site. Therefore, additional precautions are needed.

Follow the safety precautions:

Follow the safety precautions:

■ During laser welding, the operator and nearby personnel must wear the required PPE, including: (1) the specified laser safety goggles, (2) a welding helmet with appropriate filters, (3) laser and heat resistant gloves, (4) laser and heat resistant clothing, and (5) a laser and heat resistant apron.

■ In the welding area, all personnel should have their sleeves and collars buttoned.

■ Do not touch hot areas, including the welded workpiece and the hot parts of the welding head (such as the nozzle and the graduated tube), without protection shortly after laser emission.

■ To process highly reflective metals such as aluminum, you shall understand the expected cone of specular reflection for each part to be processed. Do not attempt to look at the workpiece part being welded and do not place any part of your body within the expected specular reflection cone. In addition, observers must also be aware of laser reflections at all times.

■ Follow the operational instructions to select a proper processing mode based on the material type and thickness, and set the processing parameters correctly. If the processing parameters are incorrect, the target object may fail to melt and more reflections will be produced.

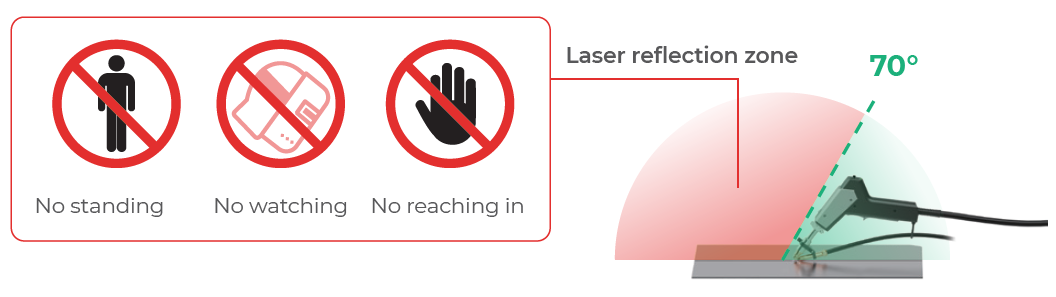

■ During processing, always maintain a 30° to 70° angle between the welding head and the welding plane.

■ During welding, ensure that no one stands in the laser reflection zone, watches from the reflection zone, or places a hand to the reflection zone.

■ When observing the welding process, stay at a safe place and watch out for the danger of multiple laser reflections.

Laser beams can reflect from multiple surfaces. Always be aware of the potential danger of multiple reflections during welding.

3. Gas cylinder safety

If cylinders containing shielding gas are damaged or placed near the welding area, they may explode, causing injury and property damage. Injury is also possible if a cylinder tips over.

Follow the safety precautions:

Follow the safety precautions:

■ Use gas cylinders that meet the requirements for using this product. The gas type should be nitrogen or argon, with a purity of more than 99.99%. For laser welding and laser cleaning, the gas flow rate should be between 15 L/min and 30 L/min. For laser cutting, the gas pressure should be between 600 kPa and 800 kPa.

■ Use gas cylinders of up-to-standard quality. Ensure that the cylinders have valid inspection certificates and clear markings. Do not use expired or obsolete cylinders.

■ Before using a gas cylinder, please carefully read and strictly follow all safety and operational instructions for the cylinder. The user is responsible for determining the suitability of the cylinder and the Company shall not be liable for cylinder products or services provided by third parties.

■ Place gas cylinders away from heat sources, sparks, flames, and laser beam deflection.

■ Do not place gas cylinders in direct sunlight.

■ Store or place gas cylinders upright and secure them with proper devices.

■ Do not strike or crash gas cylinders. When transporting and storing cylinders, use proper tools for protection, such as protective caps and shockproof rings.

■ Check the gas cylinders regularly for leaks and damage.

■ Do not use damaged gas cylinders.

■ Use a proper gas regulator to meet the flow rate and gas pressure requirements.

4. Chemical safety

For laser welding, the high-energy laser beams cause the welding wire and the welded workpieces to melt rapidly, forming a mixed molten pool, which then cools down and forms a strong connection between the workpieces. For laser cutting, the high-energy laser beams cut the material by vaporizing it. Whether it is laser welding or laser cutting, the temperature of the material will rise sharply, generating toxic and harmful fumes and gases that are hazardous to human health.

In addition, the ultraviolet light produced during welding can react with the oxygen and nitrogen in the air to produce ozone and nitrogen oxides, which are harmful to human health and can be fatal in high concentrations. Shielding gas used in welding may also have an impact on human health. High concentrations may cause suffocation.

Follow the safety precautions:

Follow the safety precautions:

■ Ensure that the working area is well-ventilated. Welding in poorly ventilated confined spaces is extremely dangerous, as the concentration of toxic fumes and gases can increase rapidly, causing unconsciousness or death from suffocation.

■ Install proper exhausting and purifying equipment in the working area to absorb toxic fumes and gases and purify them before exhausting them to the outdoor environment.

■ Do not process any material that contains PVC or vinyl. (Processing plastics is prohibited.) These materials (and other materials containing chlorine/chloride) can generate corrosive vapor that is extremely harmful to the human body and can cause damage to the product.

■ Do not process any unknown materials. Vaporization or melting of many materials, which include but are not limited to PVC and polycarbonate, may release harmful smoke.

■ Before processing a material, ensure that you fully understand the material’s properties. Please carefully read and strictly follow the material's safety data and precautions for use. In addition, you shall also know the possible by-products of the material (including the impurities, fillers, and coatings it may have) at high temperatures. Assess their potential health hazards and take necessary precautions to ensure safety.

■ During material processing, wear a dust mask and/or other necessary PPE.

■ To avoid inhaling toxic and harmful fumes and gases, do not get too close to the material during processing.

■ Monitor the air quality regularly to determine the level of toxic and hazardous fumes and gases in the working area.

■ Exhaust emissions should comply with the local laws, regulations, and standards.

5. Fire safety

During laser processing, high-energy laser beams hit on the material and generate a large amount of heat and even sparks. If there are flammable or explosive objects placed around the working area, the energy generated by the laser may cause the objects to burn or explode.

Follow the safety precautions:

Follow the safety precautions:

■ Familiarize yourself with fire safety knowledge.

■ Equip your workspace with fire extinguishing equipment, including CO2 extinguishers and sprinklers, and perform regular inspection and maintenance on them. Keep the CO2 extinguishers on hand, and all personnel should be trained in the usage of the extinguishers.

■ Within 10 meters of this product, do not place flammable, explosive, or volatile materials (including paper, acetone, alcohol or gasoline). They may cause the spread of flames and increase the risk of material ignition.

■ Ensure that the area around the product is clean and neat and that the workspace is well-ventilated so that the generated smoke can be discharged in time.

■ Do not leave the product unattended when it is working. If the product works with setting errors and is left unattended for a long period of time, or if a mechanical or electrical fault occurs, a fire may be caused.

■ Never process containers that contain flammable or combustible materials.

■ Place and use the product in locations where children are not likely to be present.

■ Each time after you finish processing, immediately remove the processed material, carefully inspect the working area of the machine to ensure no flames remain, and then clean the processing area. Otherwise, the accumulation of residues and chippings from cutting and engraving would pose a fire risk.

6. Electrical safety

Use of non-compliant power supplies can cause damage to the device and the power circuit, resulting in property damage or injury. Touching live parts of the device directly or indirectly can cause injury or even death.

Follow the safety precautions:

Follow the safety precautions:

■ Ensure that the power supply meets the requirements:

xTool MetalFab Laser Welder 1200W: individual branch circuit, 200 V – 240 V AC, 4200 W rated power, current-carrying capacity ≥ 25 A

xTool MetalFab Laser Welder 800W: individual branch circuit, 220 V – 240 V AC, 3 kW full load power, current-carrying capacity ≥ 20 A

■ When using xTool MetalFab Laser Welder 1200W, ensure that the current-carrying capacity of your circuit meets the requirements. Do not connect the product to a standard household circuit, as it may damage both the product and the circuit.

■ Ensure that the product is properly grounded. If the circuit you are connecting to is not grounded, please use the earth cable to connect the product to the ground.

■ Wiring operations should be performed by professional electricians. Wiring shall comply with national and local regulations.

■ It is recommended to install an air circuit breaker between the product and the power supply:

xTool MetalFab Laser Welder 1200W: Install a 25A air circuit breaker

xTool MetalFab Laser Welder 800W: Install a 20A air circuit breaker

■ Do not disassemble the product or change its structure in any way without authorization.

■ Ensure that the wiring is correct and the product is properly grounded before you turn it on.

■ Do not open any access panel on the product when the product is connected to the power supply. Accidental contact with the power supply may cause injury.

■ Do not touch any electronic area with your hands or other tools when the product is connected to a power supply.

■ Turn off the device after the processing is completed.

7. Noise level

This product can produce sound up to 90 db(A) in some conditions of use. This level may be considered hazardous by some authorities.

Follow the safety precautions:

Follow the safety precautions:

■ The sound pressure level should be measured in conditions of actual use.

■ If necessary, wear protective ear plugs and/or use other noise reduction devices such as barriers or baffles.

■ Follow local regulations and laws to deal with the noise.

8. Use and maintenance

Intended use

This product is designed to be used only by professionally trained personnel within the laser controlled area. It cannot be used in residential areas. Proper PPE must be worn during use.

The product is applicable for metal welding, cleaning of metal surfaces, and metal cutting. Supported materials include stainless steel, carbon steel, galvanized steel, aluminum, and brass.

Non-intended use (foreseeable misuse)

All users of this product should be trained in welding and laser safety and must comply with all instructions and safety warnings in the Safety Instructions and Quick Start Guide supplied with this product, all safety labels on the product, and all applicable safety standards, laws, and regulations.

The following situations are considered product misuses and should be strictly prevented and prohibited:

![]() Using the product in residential areas.

Using the product in residential areas.

![]() Untrained personnel using the product.

Untrained personnel using the product.

![]() Inadequate safety measures in the working area.

Inadequate safety measures in the working area.

Required safety measures include: (1) establishing a laser controlled area with an interlocked entrance; and (2) providing proper PPE (including laser safety goggles, welding helmets with appropriate filters, laser and heat resistant gloves, clothing, and aprons) for all people within the laser controlled area.

![]() Modification or conversion of the product by the user or others without the express written authorization of the Company.

Modification or conversion of the product by the user or others without the express written authorization of the Company.

![]() Intentionally disabling or bypassing product safety systems.

Intentionally disabling or bypassing product safety systems.

![]() Using parts and consumables (excluding safety-compliant PPE), such as lens protectors and nozzles, supplied by other manufacturers.

Using parts and consumables (excluding safety-compliant PPE), such as lens protectors and nozzles, supplied by other manufacturers.

![]() Removing or defacing safety labels and hazard notices.

Removing or defacing safety labels and hazard notices.

![]() Using the product to process materials that are not included in the intended applications.

Using the product to process materials that are not included in the intended applications.

![]() Processing on containers containing flammable, combustible, or unknown materials.

Processing on containers containing flammable, combustible, or unknown materials.

![]() Holding the workpiece in your hand during processing or pointing the welding head in any other way towards any individual's body parts.

Holding the workpiece in your hand during processing or pointing the welding head in any other way towards any individual's body parts.

Please use this product for its intended purpose and follow the operating principles:

Please use this product for its intended purpose and follow the operating principles:

■ Never attach the clamp of the workpiece sensing cable to the graduated tube of the welding head.

■ The device works properly at the temperature of –10°C to +40°C and at the humidity of 10% to 85%, and can be stored properly at the temperature of –10°C to +60°C.

■ Place and use the product on a stable, flat, and non-flammable surface. Keep the workspace clean and neat.

■ Do not disassemble the product or change its structure in any way without authorization. Do not modify or decompile its operating system.

■ Check the product for damage every time before you use it. Do not operate it in any way when any damage or defect is found.

■ If a consumable part of the device is damaged, follow the operational instructions to replace the part.

■ Do not leave the product unattended during operation. When the product is working, pay attention to its working status, the light of the status indicators, and the information displayed on the touchscreen controller.

■ Keep the laser processing area clean. Excessive accumulation of residues and chippings from material processing would increase the risk of fire. Please clean them immediately after each operation.

■ Cut off the power before maintaining the product.

■ This product is not user-serviceable. It must be returned to the factory or repaired by authorized professionals.

■ Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

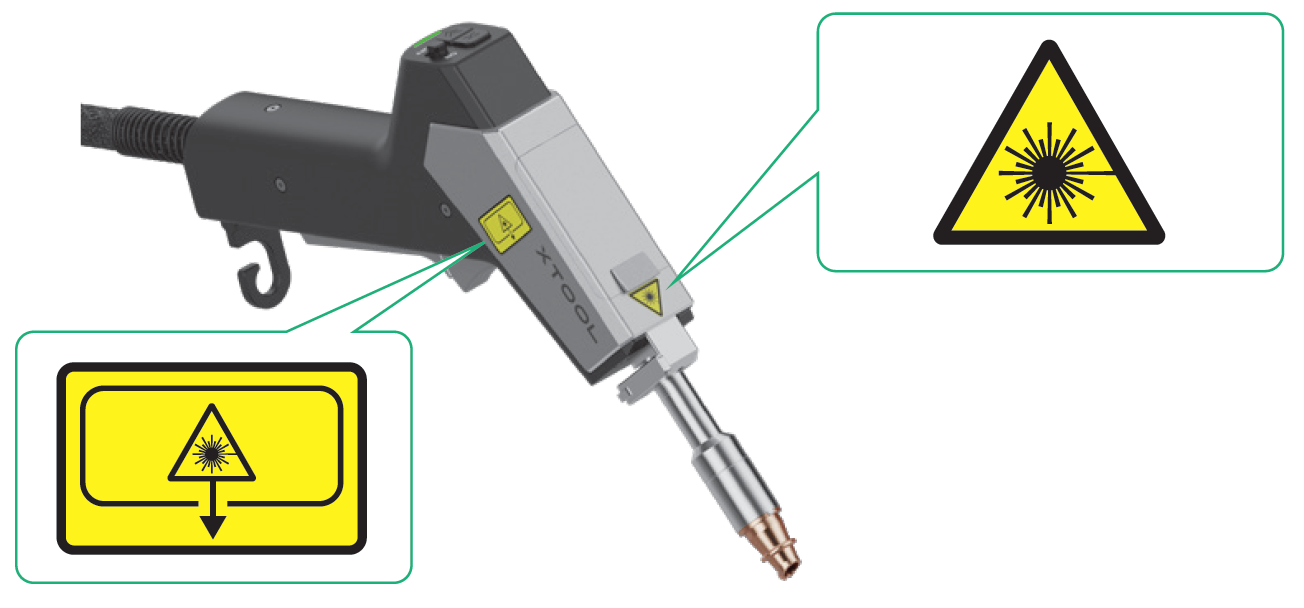

9. Warning and instruction signs

On the product, the warning and instruction signs are labeled where physical injuries or damage to the product may be caused before and/or during operation. If a sign is damaged or lost, replace it immediately. You can use the following template to print the sign you need.

- xTool MetalFab Laser Welder 1200W:

- xTool MetalFab Laser Welder 800W:

Laser specifications

Laser type | Laser safety level | Wavelength | Maximum power output |

Working laser | Class 4 | 1080 ± 10 nm | 1200 W (For xTool MetalFab Laser Welder 1200W) 800 W (For xTool MetalFab Laser Welder 800W) |

Indicator laser | Class 1 | 640 ± 10 nm | 0.39 mW |

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.