Issue description

When using xTool Apparel Printer, you may encounter a "Printer film jam" error message displayed on either xTool Creative Space (XCS) software or the LCD control panel of the printer.

- This comprehensive guide will help you diagnose and resolve this issue efficiently.

Possible causes:

- There is an actual physical jam of the film.

- The film jam sensor inside xTool OS1 Automatic Shaker Oven Machine is dirty, triggering false readings.

- The film roll is skewed or unevenly wound.

- The film is not correctly aligned with the right white guide line on the processing area of the printer.

- The printer and OS1 Oven are not assembled or connected correctly.

Troubleshooting

STEP1: Check for actual film jam

- Listen for Strange Sounds:

- An actual film jam typically produces distinctive "clicking" or "crashing" sounds from the shaker oven.

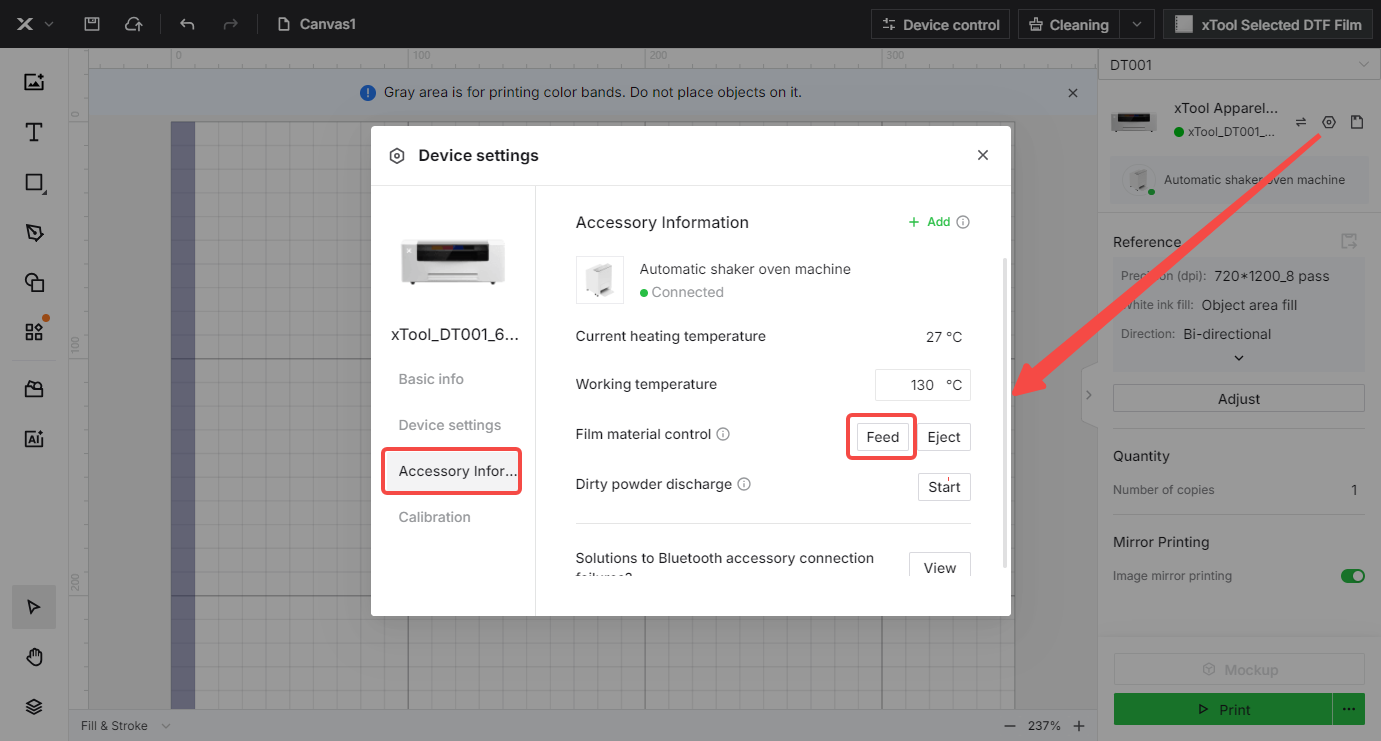

- Use the Film Feed Function:

- Navigate to: xTool Creative Space > Device settings > Accessory information > Film material control

- Click the "Feed" button to force the jammed PET film out of the delivery slot.

- Manual Removal (if needed):

- If automatic feeding fails, allow the shaker oven to cool completely.

- Open the maintenance door and carefully remove the jammed film by hand.

|

- No Actual Jam:

- If you determine that there is no material jam, the error may be a false alert from the device. Proceed to Step 2.

STEP2: Clean the film jam sensor

Tools required: Cleaning brush (Included in your package)

Sensor contamination is a common cause of false "film jam" errors.

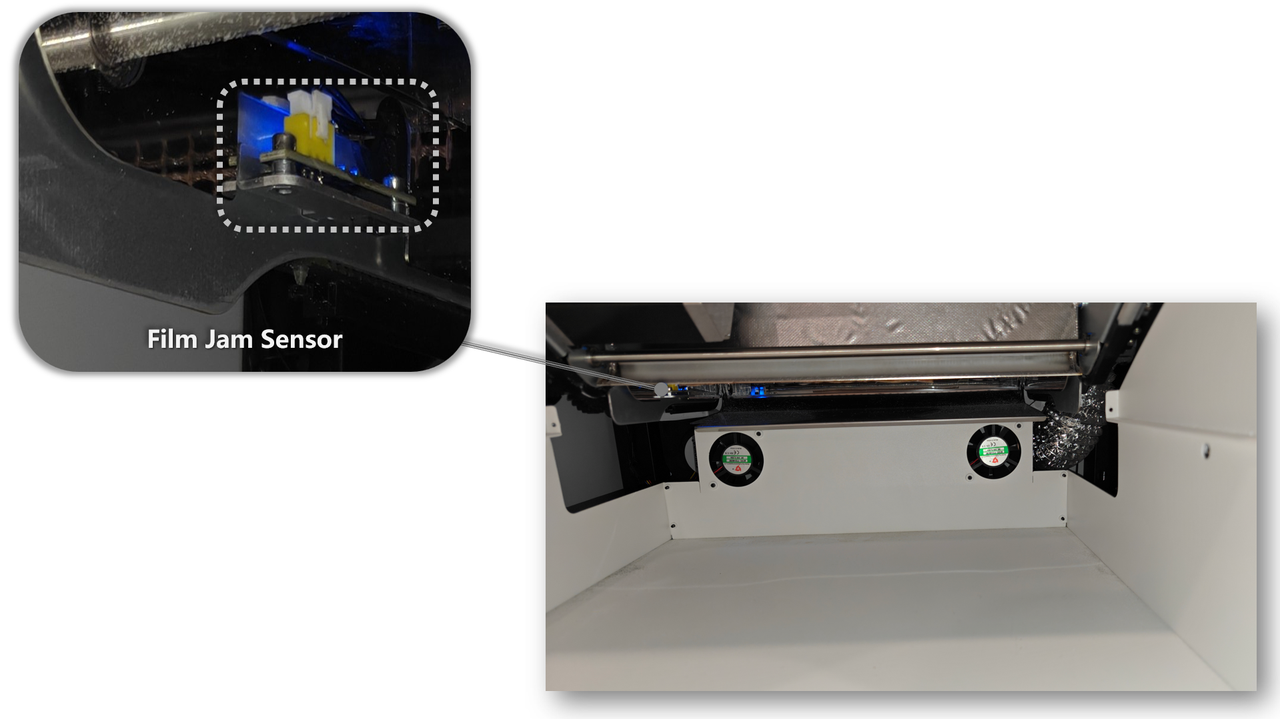

- Access the Sensor:

- Slide out the used powder bin of the oven machine to access the film jam sensor; locate the sensor as illustrated in the image below.

- Brush the Sensor:

- Using a cleaning brush, gently brush away any dust or debris from the sensor.

- Reassemble & Test:

- Reinstall the waste powder container securely.

- Try operating the machine again. If the error message persists, continue to the next step.

|  |

STEP3: Verify film-roll alignment

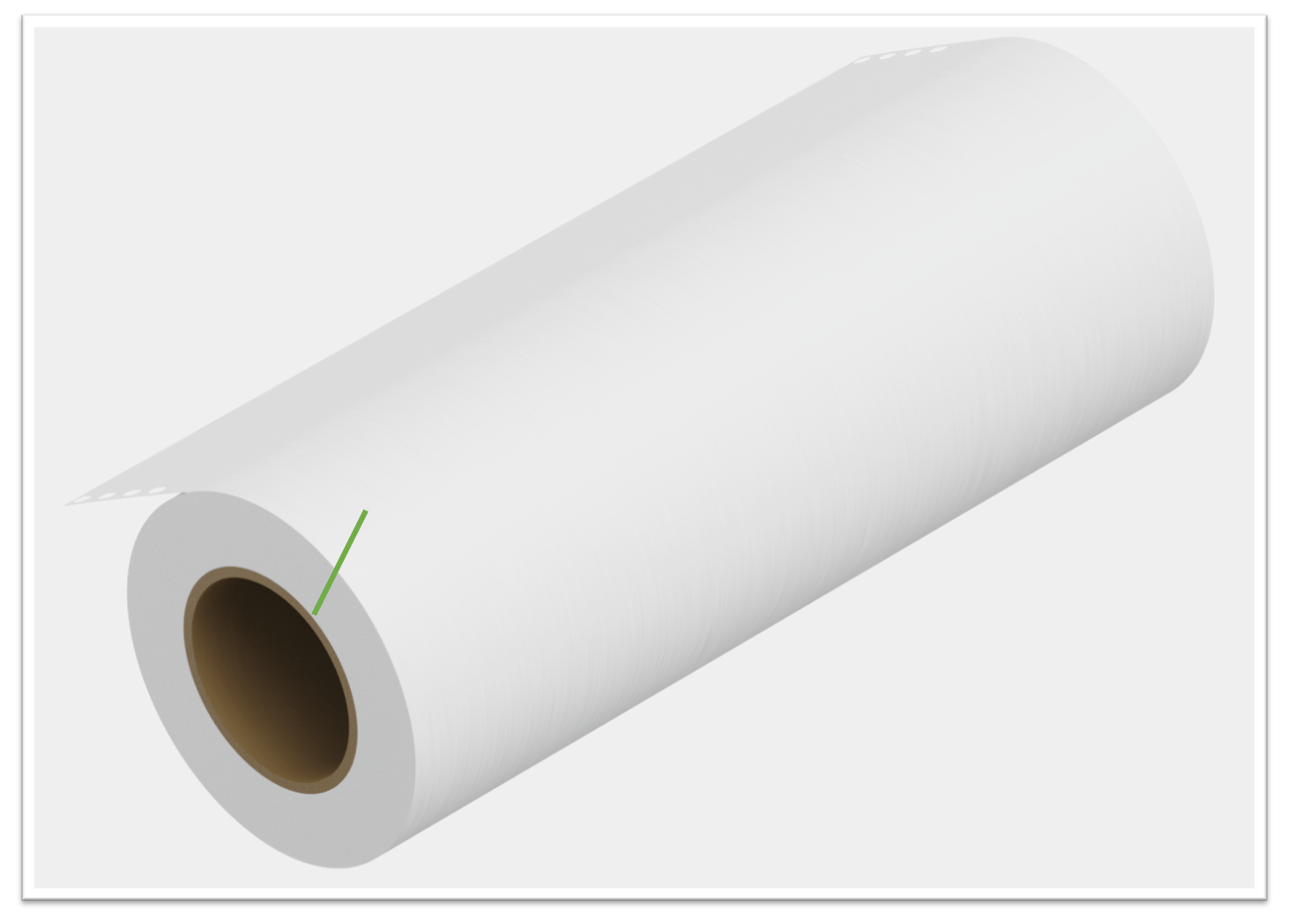

- Check for misalignment:

- An unevenly wound film roll or improper loading can trigger the jam sensor or cause feeding problems.

- Visually inspect the film roll currently loaded onto the printer from the side to check for uneven winding, telescoping, or skewing.

|  |

- If the roll appears uneven/skewed:

- Carefully remove the film roll from the printer.

- Place it on a clean, flat surface (e.g. a table).

- Gently tap the ends of the roll flat against the surface to help even out the winding.

- Reinstall and test.

- Proper Film Alignment:

- When reinstalling the film holder and roll, align the film edge precisely with the white marking line.

- The film must not overlap the white marking line.

- The film edge must remain within ≤1 mm of the line (not shifting left or right).

- If you cannot adjust the telescoped film roll or prefer not to attempt adjustment, please proceed to the "Still experiencing issue" section.

- If the film roll appears to be wound correctly and loaded properly, proceed to the next step.

STEP4: Perform “Device self-check”

- Restart both devices:

- Power off the printer and oven; await 30 seconds before rebooting.

- Run “Device self-check”:

- On the control panel of the printer, tap Maintenance > Device self-check > Start and follow on-screen prompts.

- If the detection test fails:

- Refer to: Troubleshoot "Device Self-Check" Failure for xTool Apparel Printer & xTool OS1 for troubleshooting.

- If the error remains unresolved after following the previous steps, it might be necessary to replace one or more components. Proceed to the "Still experiencing issue" section to contact xTool Customer Service for further assistance.

Still experiencing issues?

Should the issue persist after completing the preceding steps, submit a ticket via the "Submit a Ticket" button in the "Help Ticket" section below. The standard response time for xTool Customer Service is one business day.

For a prompt resolution, please include the following details:

- Issue Description: A detailed explanation of the observed problem.

- Video Evidence: Attach a video demonstrating the issue, where applicable.

- Troubleshooting Performed: Any troubleshooting steps you have already attempted, along with their results.

This information is crucial for xTool technical support engineers to provide timely assistance.

Documentation feedback

Help improve this content by providing feedback. If this content did not meet your requirements, select "No" in the "Was this page helpful?" section below. Include specific details about what was unclear or missing in the pop-up suggestion box. Feedback submissions are reviewed by xTool technical writers to enhance future documentation.

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.