Issue description

You may encounter an "Exceptions occur" error in your xTool Creative Space (XCS) software, which indicates a significant airflow obstruction within the system. The symptoms vary depending on how your laser machine is connected to the xTool Air Purifier 2 (AP2).

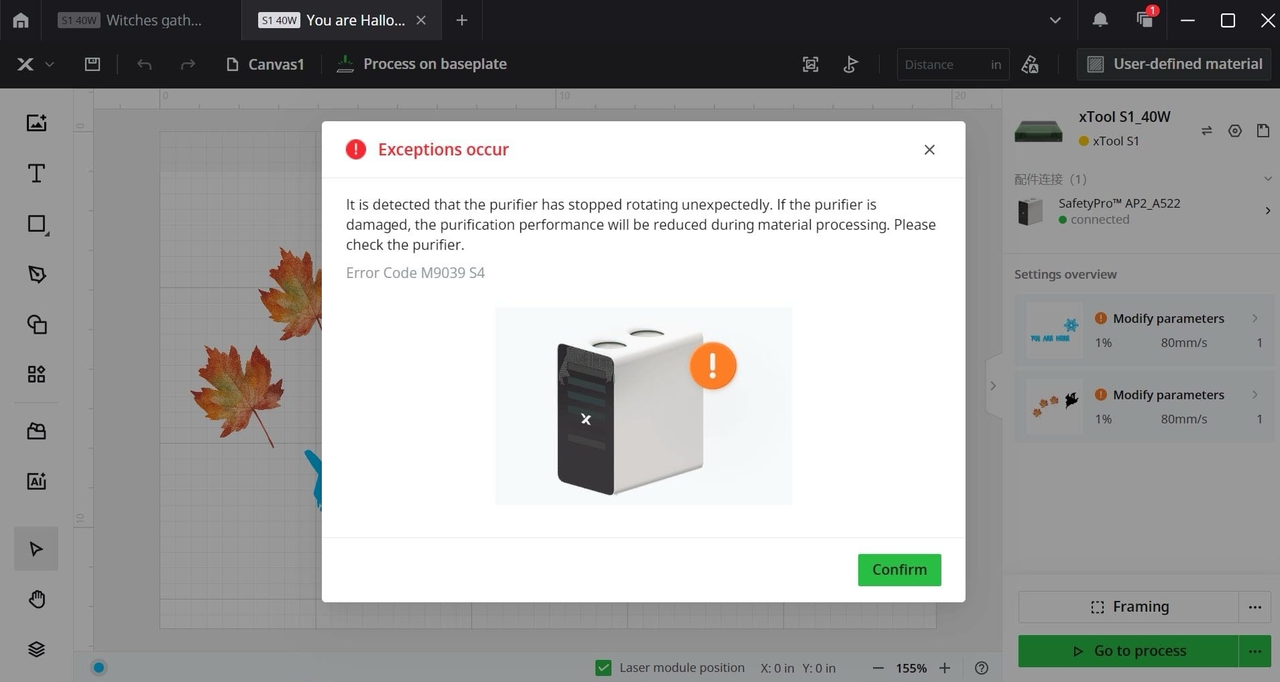

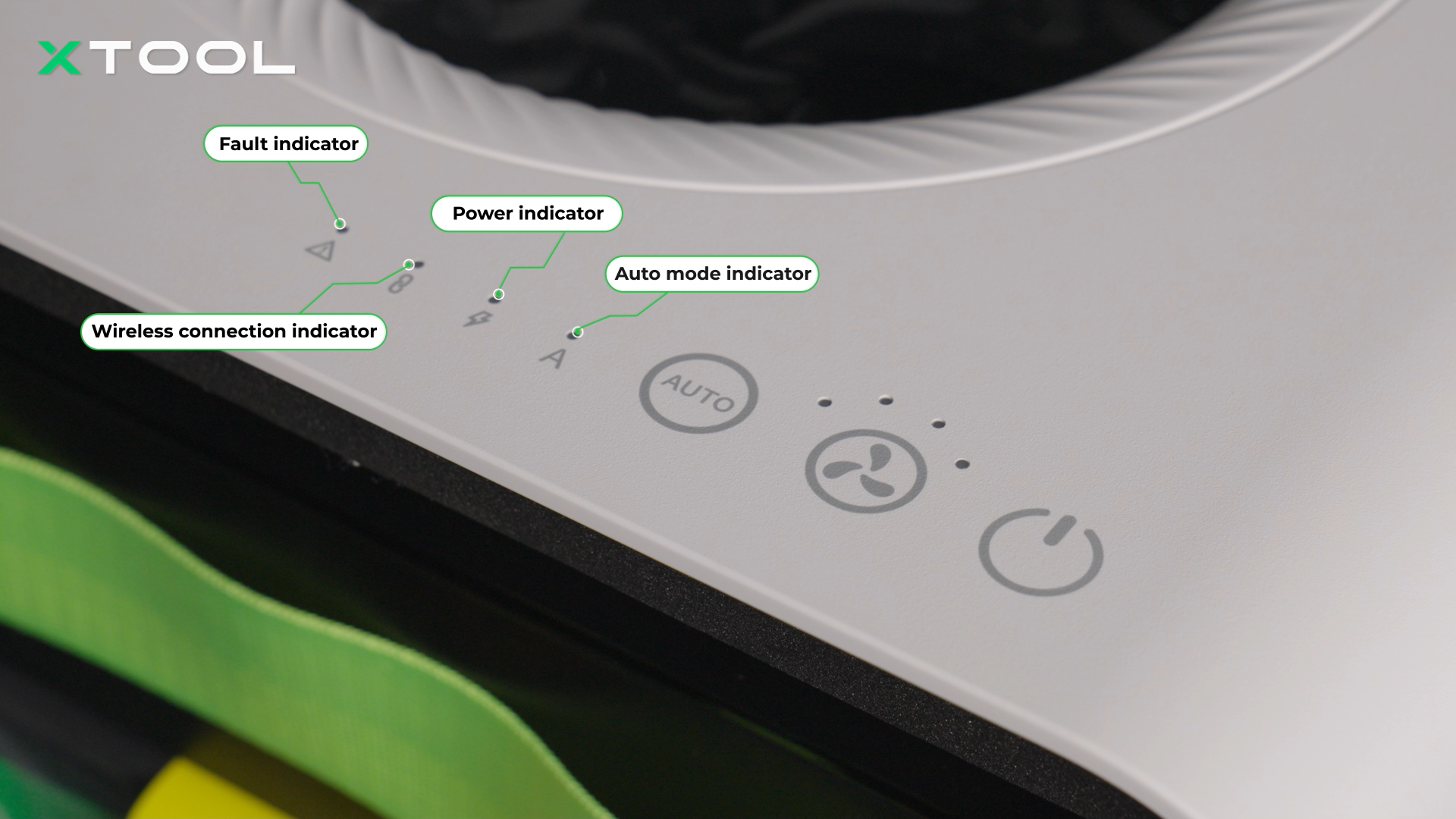

- For Bluetooth Dongle Connection Laser Devices (e.g., M1 Ultra, S1): A pop-up message stating "Exceptions occur" with the error code M9039 S4 appears in the xTool Creative Space (XCS) software. The AP2 will stop running, and its fault indicator light will turn solid red.

- For Non Bluetooth Dongle Connection Laser Devices (e.g., P2, F1): The XCS software will not display an error pop-up. But you may encounter an unexpected operation halt where the AP2 will stop running mid-operation, and its fault indicator will turn solid red.

|  |

Potential causes

- The exhaust system of the connected laser device is clogged.

- The air inlet or outlet on the AP2 is blocked.

- The Cyclone tray or the filter cartridge(s) inside the AP2 are clogged.

Troubleshooting procedures

Step 1: Clean/remove engraver's exhaust system

Only xTool S1, F1 Ultra, M1 Ultra, and P2S models are compatible with Bluetooth dongle connection.

For Bluetooth dongle connection models:

xTool M1 Ultra:

- When using AP2 with M1 Ultra, you must remove the built-in exhaust fan from your xTool M1 Ultra and the filter cotton inside the smoke exhaust module.

- Refer to the video tutorial below for detailed fan removal instructions.

|  |

xTool P2S:

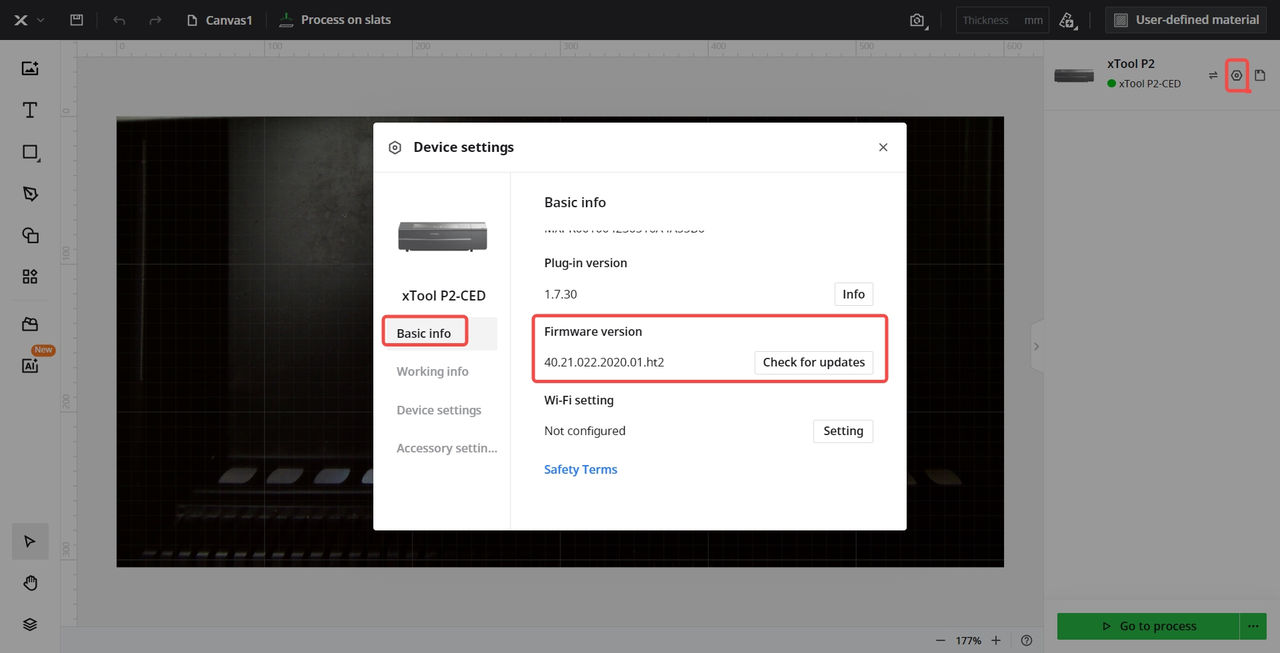

- Ensure the firmware of your xTool P2S is up-to-date.

- In XCS, navigate to Device settings > Basic info > Firmware version and click Check for updates.

- Inspect the P2S filter screens (located above the internal processing area) for blockages.

- Clean the filter screens if necessary according to the video tutorial: How to Clean the Filter Screens of P2S

|  |

xTool S1:

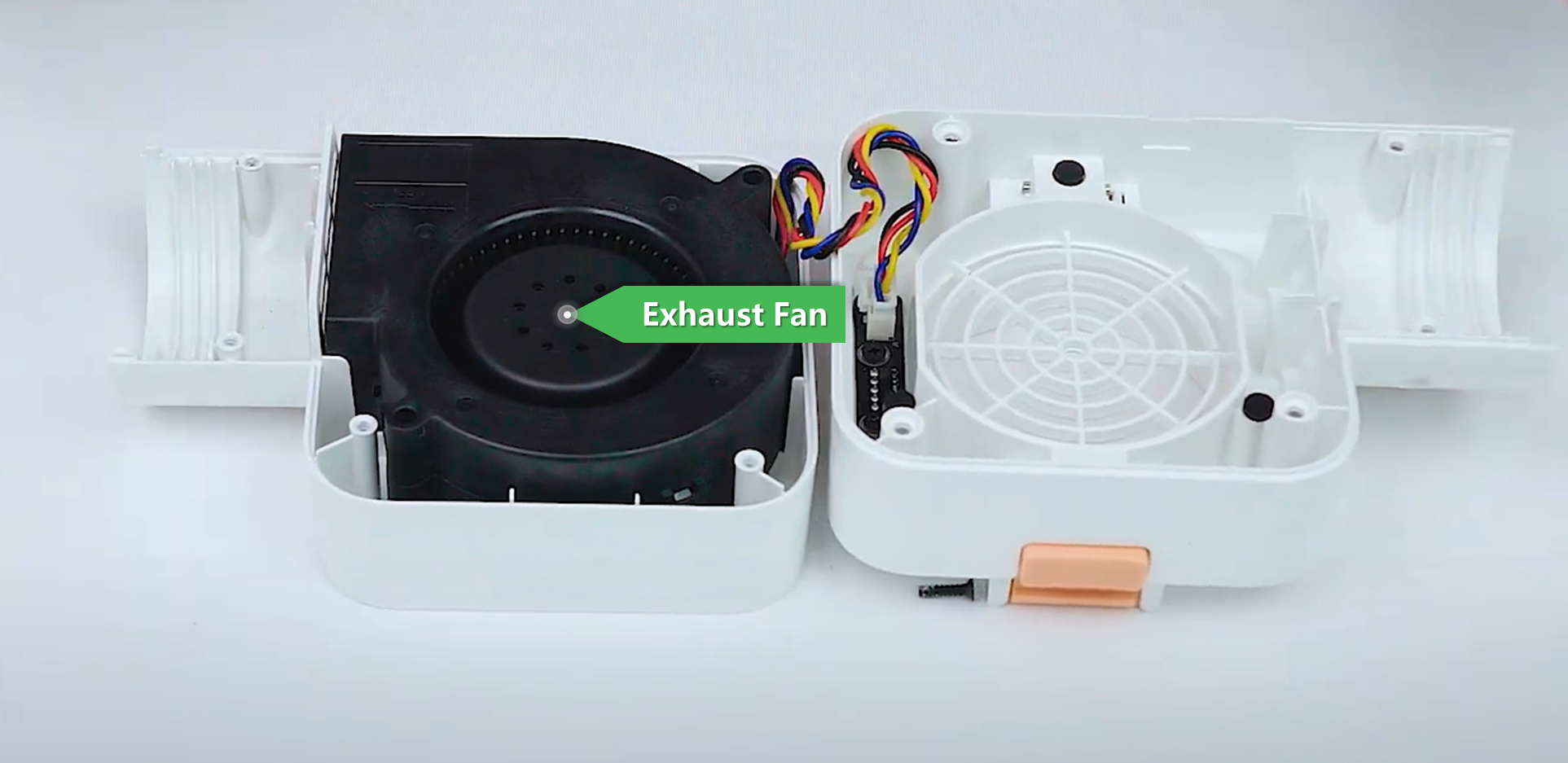

- Inspect the exhaust fan of your xTool S1 for dirt buildup.

- Clean the fan if necessary according to the video tutorial below.

xTool F1 Ultra:

- Inspect the exhaust fan of your xTool F1 Ultra for dirt buildup.

- Clean the fan if necessary according to the video tutorial below.

For other models:

xTool P2:

- Inspect the exhaust fan of your xTool P2 for dirt buildup.

- Clean the fan if necessary according to the video tutorial below.

xTool F1/F1 Lite:

Inspect the exhaust fan of your xTool F1/F1 Lite for dirt buildup.

- Clean the fan if necessary.

- Use a cotton swab dampened by anhydrous ethanol to clean the fan and outlet

- Slightly tilt the device while cleaning to avoid dust falling into the internal.

If the issue persists after cleaning or removing the laser engraver's exhaust fan, proceed to the next step.

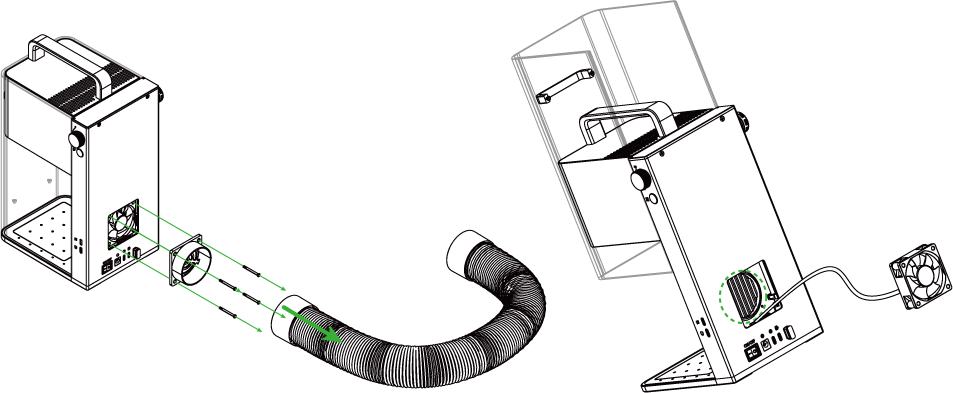

Step 2: Inspect & clean air inlet and outlet

- Disconnect the exhaust pipes from both the airflow inlet and airflow outlet on your xTool AP2.

- Inspect the pipes and the outlets themselves for any blockages or accumulated debris.

- Clean the inlet and outlet ports thoroughly

- After cleaning, restart the AP2 and test if the issue is resolved. If not, proceed to the next step.

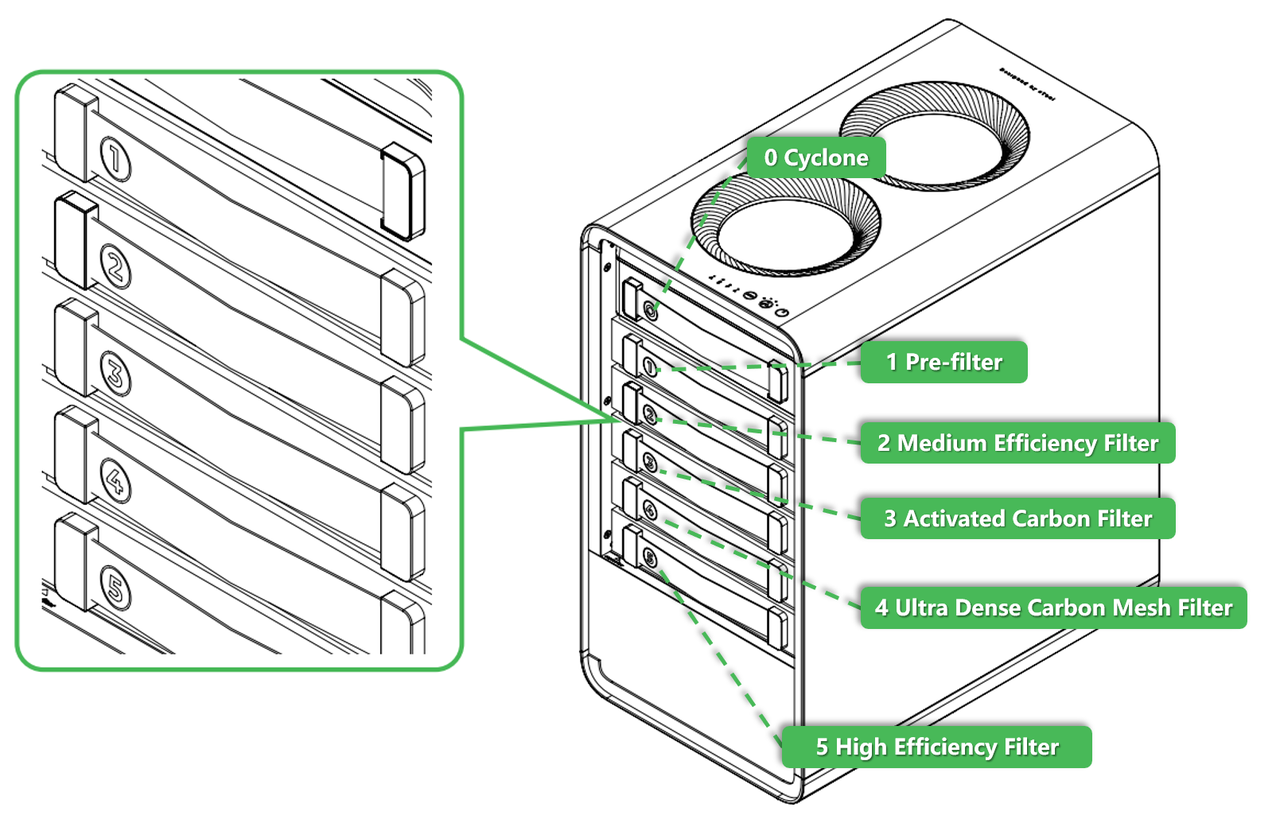

Step 3: Inspect & clean the AP2 Cyclone and filters

Clean the Cyclone tray:

- The cyclone tray separates larger particles. If clogged, it will severely restrict airflow.

- Remove and clean the cyclone tray. After washing, ensure it is completely dry before re-installing.

- Refer to the unboxing video at approximately 1:20 - 1:49 for Cyclone tray cleaning guidance.

- ‼️ Important: When re-installing the cyclone tray, ensure the side with the mesh screen is facing upwards.

- If the issue persists after cleaning the cyclone, continue to the next sub-step.

Clean the Pre-filter:

- Remove the Pre-filter (Filter #1).

- Take it outdoors. Gently tap it on a solid surface to dislodge loose dust and debris.

- If the issue persists, proceed to the next sub-step.

Test filter performance:

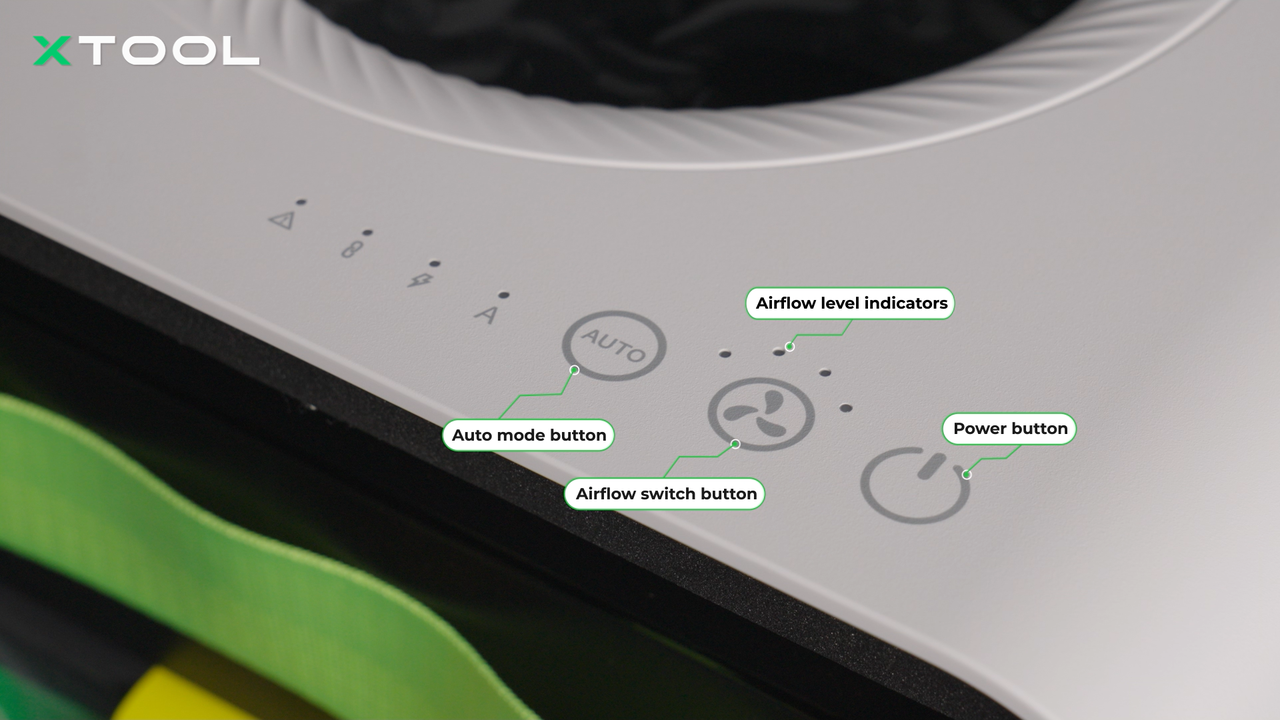

- Switch the AP2 to manual mode by tapping the airflow switch button.

- Select the appropriate setting based on your processing needs (four settings available).

- In manual mode, remove the #1 Pre-filter and set the AP2 airflow to level 4.

- Observe the AP2 operation for 2-5 minutes.

- If the AP2 runs continuously without stopping: This confirms that the No. 1 Pre-filter is clogged and needs to be replaced. You can purchase a new pre-filter from the xTool official website to resolve the issue.

- Pre-filter purchaser link: Filters for SafetyPro™ AP2

- IMPORTANT: Always swtich the website to your country/region before placeing an order.

- If the AP2 still stops with the error: The issue lies elsewhere. Proceed to the "Still experiencing issues?" section to contact xTool Customer Service.

- If the AP2 runs continuously without stopping: This confirms that the No. 1 Pre-filter is clogged and needs to be replaced. You can purchase a new pre-filter from the xTool official website to resolve the issue.

Still experiencing issues?

Should the issue persist after completing the preceding steps, submit a ticket via the "Submit a Ticket" button in the "Help Ticket" section below. The standard response time for xTool Customer Service is one business day.

For a prompt resolution, please include the following details:

- Issue description: A detailed explanation of the observed problem.

- Video evidence: Attach a video demonstrating the issue, where applicable.

- Troubleshooting performed: Any troubleshooting steps you have already attempted, along with their results.

This information is crucial for xTool technical support engineers to provide timely assistance.

Documentation feedback

Help improve this content by providing feedback. If this content did not meet your requirements, select "No" in the "Was this page helpful?" section below. Include specific details about what was unclear or missing in the pop-up suggestion box. Feedback submissions are reviewed by xTool technical writers to enhance future documentation.

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.