xTool Creative Space (XCS) provides recommended processing settings for most xTool machines to engrave the fast-engrave screens.

Unlike other materials, you need to set the processing parameters for the screens with caution to ensure that the coating (photosensitive emulsion) in the processed area is removed while the screen wires are not burnt out.

The recommended settings, however, are tested in labs and may not work the best due to laser power attenuation or other machine differences. Therefore, you are advised to test processing settings in the test screen to find out the best settings for your machine before creating your works.

The testing steps are as follows:

For xTool P2 and P2S

Method 1

- Download the following file and open it on XCS.

Test array for xTool P2 and P2S

Note: This file is made in XCS V2.3. If your XCS is an earlier or later version, the file may not work properly.

- Start processing.

Method 2

- Download the following file and open it on XCS.

Test array image for xTool P2 and P2S

- Select the object and click Ungroup on the top bar.

- Set Power and Lines per cm according to the values indicated in the object.

- Start processing.

For other xTool machines

Step 1: Download the test file and open it on XCS

The test file is as follows:

Step 2: Configure processing settings

- Click the object and set the processing type to Engrave.

- Set the Lines per cm by referring to the following table.

- For fast-engrave screens with 100 meshes

Model | Lines per cm | |

Series | Laser power | |

D1 Pro | 5 | 200 |

10 | 180 | |

20 | 160 | |

40 | 100 | |

F1 | 10 | 300 |

F1 Ultra | 20 | 220 |

M1 | 5 | 200 |

10 | 120 | |

M1 Ultra | 10 | 180 |

20 | 140 | |

S1 | 10 | 180 |

20 | 160 | |

40 | 120 | |

- For fast-engrave screens with 200 meshes

Model | Lines per cm | |

Series | Laser power | |

D1 Pro | 5 | 200 |

10 | 180 | |

20 | 180 | |

40 | 140 | |

F1 | 10 | 300 |

F1 Ultra | 20 | 300 |

M1 | 5 | 120 |

10 | 140 | |

M1 Ultra | 10 | 160 |

20 | 160 | |

S1 | 10 | 180 |

20 | 200 | |

40 | 180 | |

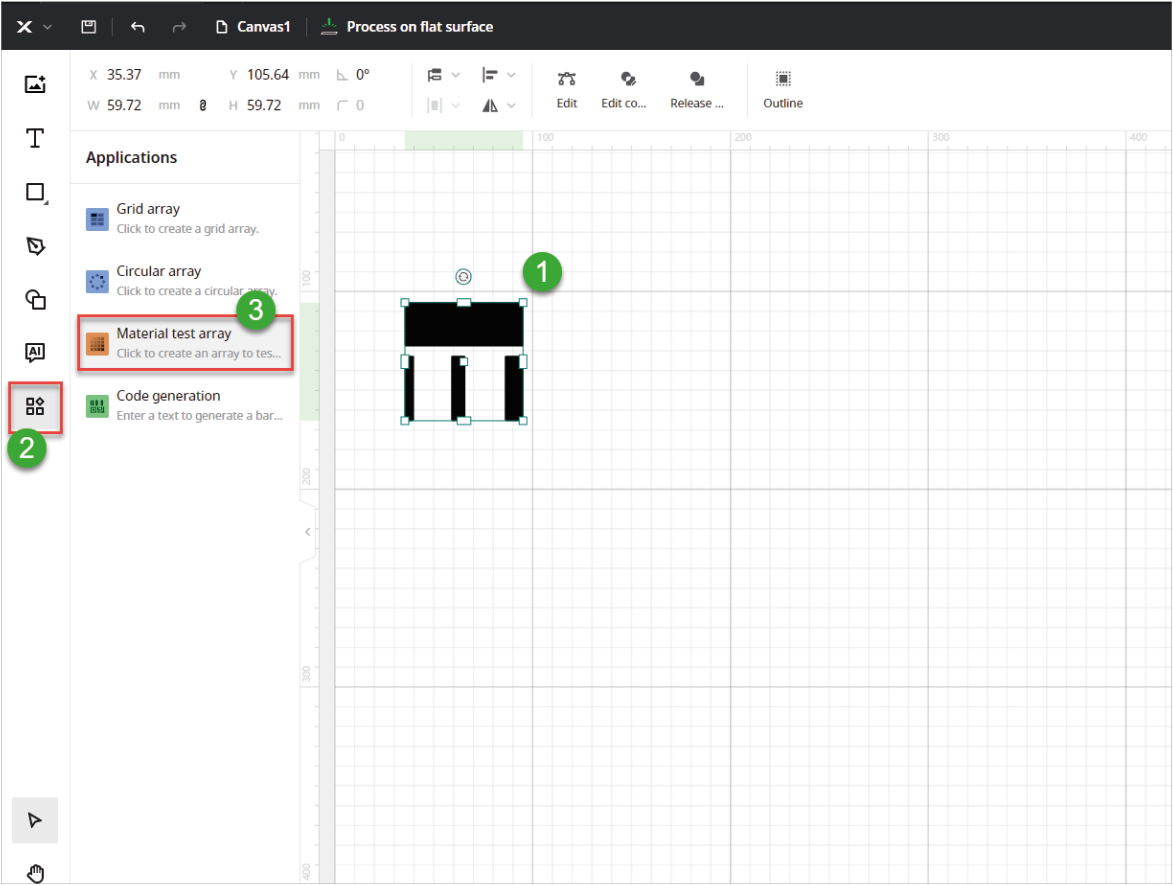

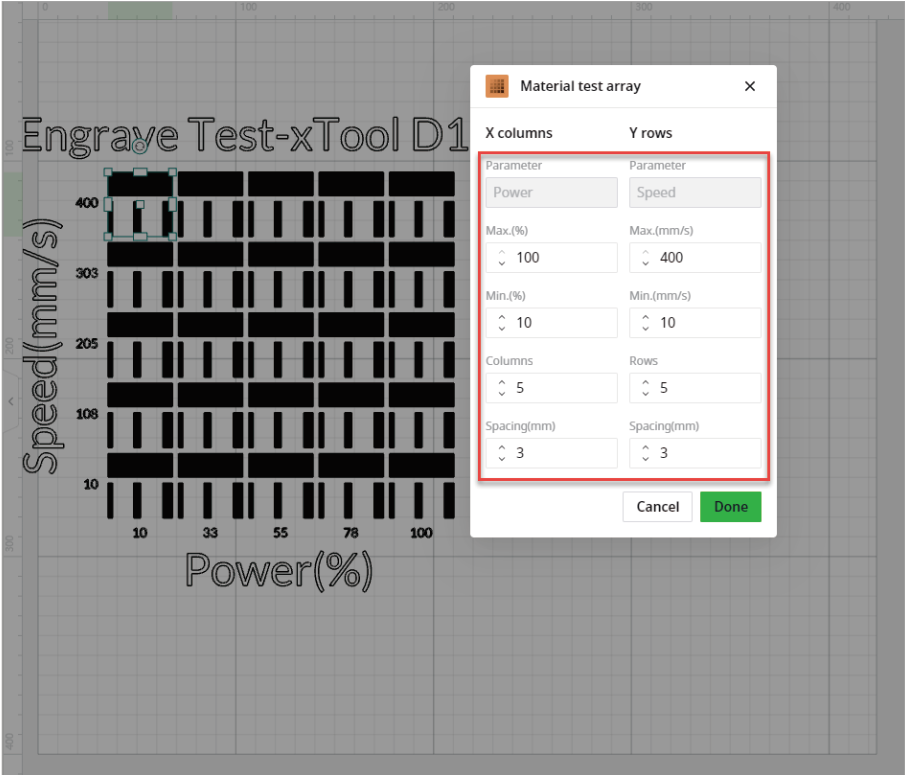

- Select the object and choose Applications > Material test array.

- Set the array parameters for your machine by referring to the following table.

- For fast-engrave screens with 100 meshes

Model | Power setting for the array | Speed setting for the array | |||

Series | Laser power | Max. (%) | Min. (%) | Max. (mm/s) | Min. (mm/s) |

D1 Pro | 5 | 40 | 20 | 210 | 190 |

10 | 25 | 5 | 260 | 240 | |

20 | 25 | 5 | 290 | 210 | |

40 | 30 | 10 | 410 | 390 | |

F1 | 10 | 40 | 20 | 910 | 890 |

F1 Ultra | 20 | 35 | 15 | 1510 | 1490 |

M1 | 5 | 40 | 20 | 210 | 190 |

10 | 27 | 7 | 260 | 240 | |

M1 Ultra | 10 | 25 | 5 | 260 | 240 |

20 | 22 | 2 | 410 | 390 | |

S1 | 10 | 30 | 10 | 260 | 240 |

20 | 30 | 10 | 510 | 490 | |

40 | 35 | 15 | 510 | 490 | |

- For fast-engrave screens with 200 meshes

Model | Power setting for the array | Speed setting for the array | |||

Series | Laser power | Max. (%) | Min. (%) | Max. (mm/s) | Min. (mm/s) |

D1 Pro | 5 | 40 | 20 | 210 | 190 |

10 | 25 | 5 | 260 | 240 | |

20 | 30 | 10 | 310 | 290 | |

40 | 25 | 5 | 310 | 290 | |

F1 | 10 | 50 | 30 | 2100 | 1990 |

F1 Ultra | 20 | 30 | 10 | 1110 | 990 |

M1 | 5 | 50 | 30 | 210 | 190 |

10 | 30 | 10 | 260 | 240 | |

M1 Ultra | 10 | 25 | 5 | 410 | 390 |

20 | 30 | 10 | 410 | 390 | |

S1 | 10 | 35 | 15 | 410 | 390 |

20 | 40 | 20 | 410 | 390 | |

40 | 30 | 10 | 510 | 490 | |

After testing

After processing the test screen with the recommended test array, check the burnt-out situation of your screen wires. If the parameter setting for the processed area helps to remove the coating properly while no wire is burnt out, you can use it as the optimal setting for your screen processing.

|  |  |

❌Wires burnt out | ❌Coating not properly removed | ✅ Coating properly removed while no polyester wire burnt out |

The preceding processing results are for reference only. You can observe your processed screen area as follows:

- Observe the processed screen area under light.

- Use a mobile phone or camera to shoot the processed screen area with a zoom range of 5 to 10 times and observe the picture.

If there're multiple settings fit for your machine, choose the one with the largest value of lines per cm. Because the higher the lines per cm, the clearer the processing result and the better coating removing result.

Note: After deciding the best settings, center the object to be processed as much as possible in XCS. If the object is close to the edges, the processing result may be poor and the screen may be worn out due to tension issues.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.