Download PDF files (multi-language)

|  |  |

|  |  |

|  |  |

|  |

|

List of items

xTool P2S |  Power cable |

USB cable (Type-C) |  Key |

Smoke exhaust pipe components |  Antifreeze |

Funnel |  Basswood 3 mm |

Transparent acrylic |  Screwdriver |

Hex key |  Material clamp |

Screw M3*6 (spare parts) |  Screw M3*22 (spare part) |

Self-Check Guide |  Quick Start Guide |

Safety Instructions |

|

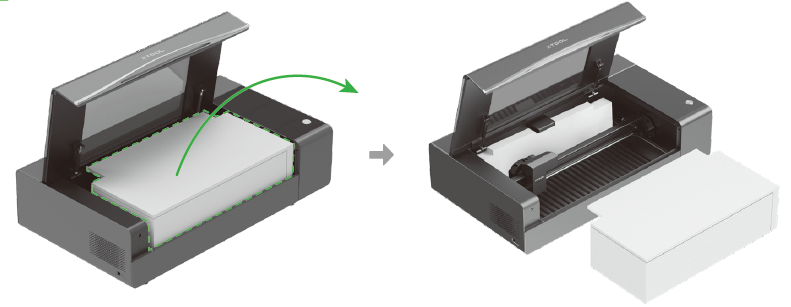

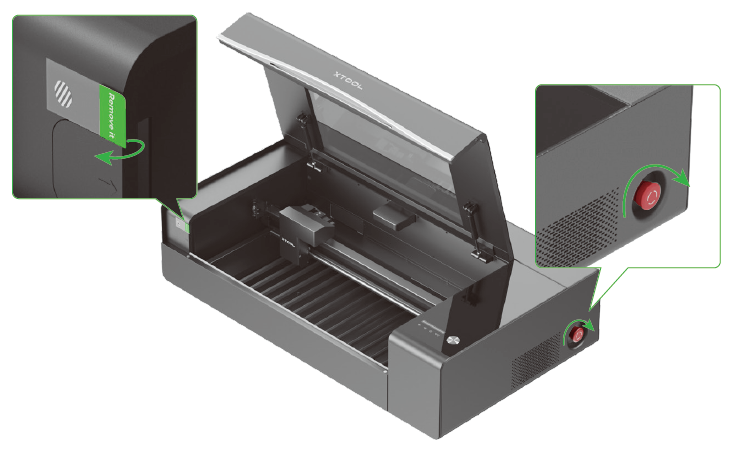

Open the box and take out all the items

1. Open the lid and take out the items.

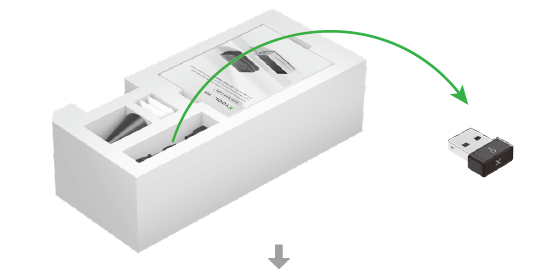

2. Take out the key and insert it into the machine.

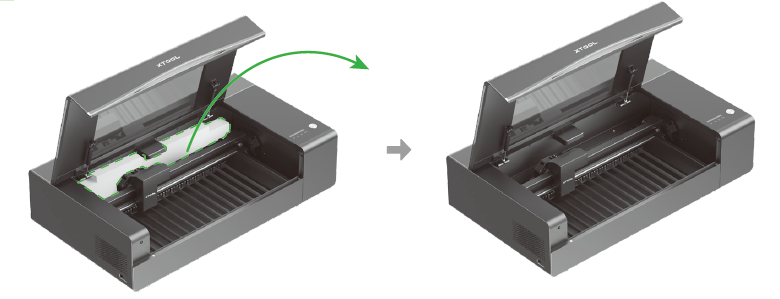

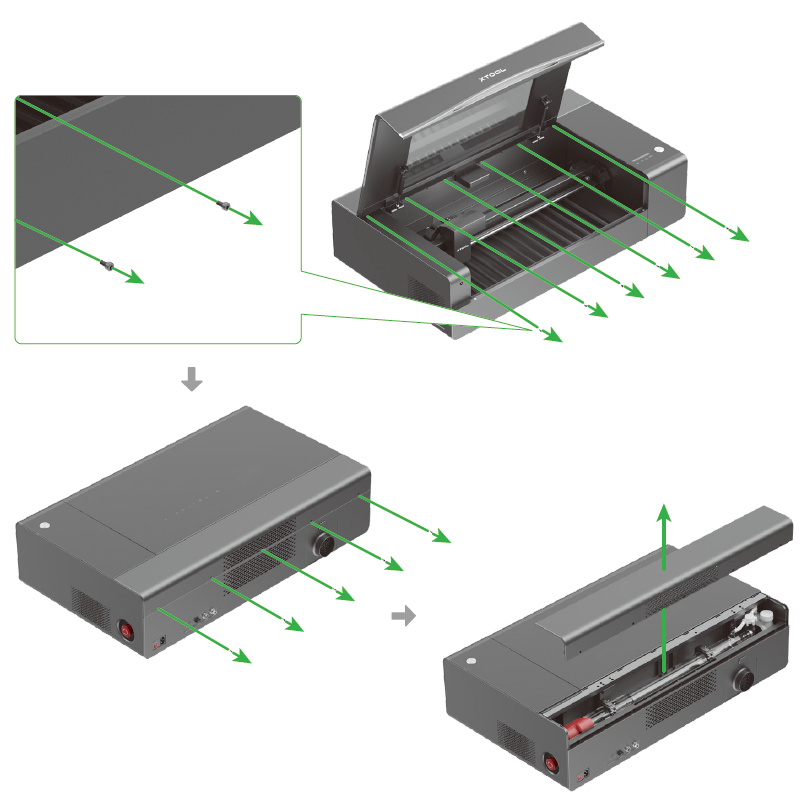

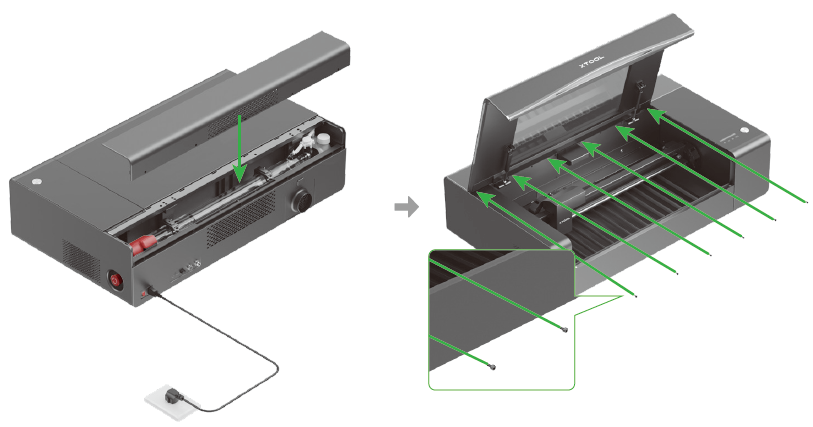

3. Remove the thumb screws and brackets at the left and right ends of the x-axis guide rail.

4. Move the x-axis guide rail forward and take out the foam.

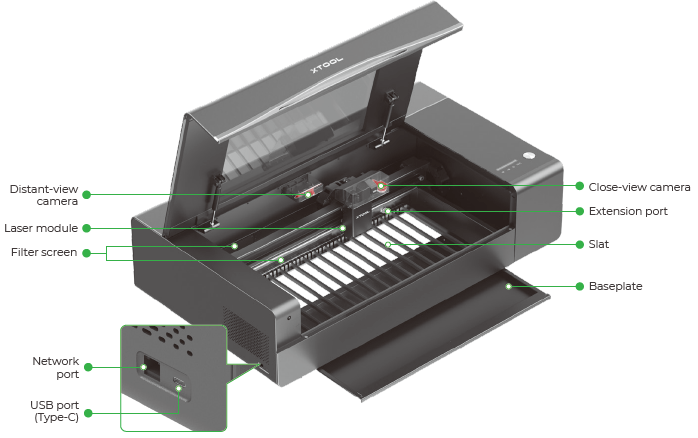

Meet your xTool P2S

Understand the indicator and state display screen

Annular indicator | Screen | Device |

Blinking white | / | Starting |

Solid white | Displays the temperature and lid locked/unlocked state | Standby, not connected |

Solid white | Displays the icon of the connection mode | Standby, connected |

Breathing green | / | Sleeping |

Blinking blue and then solid blue | / | Ready to work |

Solid blue | Progress bar blinks and moves | Performing a task |

Solid blue | Progress bar stops moving | Task paused |

Solid green | / | Task completed |

Solid white | / | Task canceled |

Solid purple | / | Firmware updating |

Solid red | Fault indicator lit up | Exceptions occur |

/ | H or L lit up | Liquid temperature alarm H: Temperature too high L: Temperature too low |

Breathing blue | / | Calibrating or image recognizing |

Solid red | / | Calibration or recognition failed. You can open and then close the lid or use XCS to bring the device back to the standby state. |

Solid yellow | / | Waiting for AP network setting. You can hold down the button on xTool P2S for 5 seconds to start AP network setting. If no network is set within 2 minutes, the device goes back the standby state. Name of the AP hotspot: XTOOL-P2S-Last 6 digits of MAC address |

Note: "/" indicates no state change.

State display screen

| 1. Progress bar, where you can see the progress of a processing task 3. The machine is connected through Wi-Fi. H: lighting up indicates that the temperature is too high L: lighting up indicates that the temperature is too low. |

Preparations

| 💡 Do not connect the machine to a power supply until you are instructed to. |

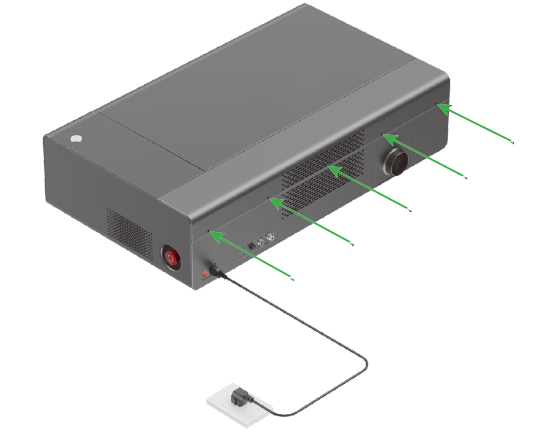

1. Check the casing of the machine. If it is severely damaged, do not use the machine and contact xTool after-sales services.

2. Remove the sticker used to prevent the lid from locking and turn the emergency stop switch to reset it.

3. Check the access-control key. Ensure that it is inserted in place.

| 💡 The key can function as both an access control key and an interlock connector. Go to xTool Access Control Key to learn more. |

4. Manually move the laser module to check whether it can move properly. If it can't, do not use the machine and contact xTool after-sales services.

5. Check the laser tube. If it is cracked or damaged, do not use the machine and contact xTool after-sales services.

(1) Unscrew the screws that fix the rear cover and remove it.

(2) Check whether the laser tube is cracked or damaged.

6. Fill the water tank with antifreeze.

You need to prepare a measuring glass to measure purified water.

If you can't find a measuring glass at home, you can store the antifreeze in another container and use the bottle of the antifreeze to measure purified water.

Note: ■ Determine the volume of antifreeze to be used according to the annual lowest temperature in your region first. ■ Ensure that you use purified water to prepare the antifreeze. Tap water contains impurities and bleach, which may cause too many bubbles, affecting the working of the laser tube and even damaging the laser tube. ■ You need to fill the water tank twice. Strictly follow the steps to fill the water tank, using the recommended volume of antifreeze and avoiding overflow. |

(1) Determine the volumes of antifreeze and purified water to be used.

- If the annual lowest temperature in your region >0°C

Annual lowest temperature in your region (℃) | Concentration (%) | First filling | Second filling | |

Antifreeze (ml) | Purified water (ml) | Purified water (ml) | ||

T >0 | 0 | 0 | 1100 | 300 |

- If the annual lowest temperature in your region ≤ 0°C

Annual lowest temperature in your region (℃) | Concentration (%) | First filling | Second filling | |

Antifreeze (ml) | Purified water (ml) | Purified water (ml) | ||

–10 ≤ T ≤ 0 | 20 | 280 | 820 | 300 |

–20 ≤ T ≤ –10 | 35 | 490 | 610 | 300 |

–30 ≤ T ≤ –20 | 45 | 630 | 470 | 300 |

–40 ≤ T ≤ –30 | 50 | 700 | 400 | 300 |

–50 ≤ T ≤ –40 | 60 | 840 | 260 | 300 |

(2) Open the cap of the water tank and insert the funnel into the opening.

(3) Complete the first filling.

Pour the required volume of antifreeze into the water tank, and then slowly pour the required purified water in. Observe the water level during the filling to avoid overflow.

(4) Connect the machine to a power supply and turn on the machine.

(5) Complete the second filling.

Wait 30s for the water level to descend in the water tank, pour the required purified water in, and then close the cap of the water tank. Observe the water level during the filling to avoid overflow.

(6) Fit the rear cover back to the machine and tighten the screws.

(7) Install the smoke exhaust pipe.

| 💡 If you have purchased a smoke purifier, follow the instructions to connect it to xTool P2S. |

Use xTool P2S

You can use the xTool official software xTool Creative Space (XCS) to operate xTool P2S. For details, see Use XCS to operate xTool P2S.

Services & Help

Learn & Community

Contact Us

Copyright © 2025 xTool All Rights Reserved.