This content is tailored for the operatation of xTool S1 with xTool Rotary Attachment 2 or xTool Conveyor Feeder.

Issue description

When using your xTool S1, you may encounter an issue where your laser device itself works properly under the "Process on basedplate" mode, but when using an accessory like the xTool Rotary Attachment 2 (RA2) or the xTool Conveyor Feeder, mechanical movement-related issues arise. Specially:

- When switching to xTool RA 2, you encounter:

- Irregular rotation or stuttering;

- Complete failure to rotate;

- Abnormal noise during movement.

- Similar issues may occur when using xTool Conveyor Feeder:

- Jerky forward/backward motion;

- No movement at all;

- Grinding or abnormal sounds.

This guide provides systematic steps to diagnose and resolve this problem.

System overview

Understanding the connection pathway helps identify potential failure points:

Signal Path:

xTool Rotary Attachment 2/Conveyor Feeder Motor → Accessory Connection Cable

→ Front Interface Board → Front Interface Board Connection Cable

→ Laser Device Main Control Board → Rear Interface Board Connection Cable

→ Rear Interface Board → (Connected Devices: Air Assist Set or Fire Safety Set)

Any failure in this chain could result in malfunctions.

Common causes

- Failure within xTool Rotary Attachment 2 or xTool Conveyor Feeder itself;

- Rear Interface Board failure;

- Front Interface Board or Front Interface Cable failure;

- Mainboard failure;

Troubleshooting procedures

Step 1: Check accessory hardware

Purpose: Determine if the accessory itself has mechanical issues causing stuttering or blockage.

Test A: Power-off manual operation

- Power down your xTool S1 main unit completely.

- Test manual operation:

- For xTool RA 2: Manually rotate the attachment by hand.

- For xTool Conveyor Feeder: Manually push/pull the conveyor belt.

- Evaluate results:

- Stiff, blocked, or jerky movement: The accessory hardware is experiencing failures and needs replacement*.

- Smooth movement: Proceed to Test B/C.

*To request a replacement, please contact xTool Customer Service by submitting a request in the Help Ticket section below. Select Buy after-sales materials under the After-sales Issue tab to place your replacement order.

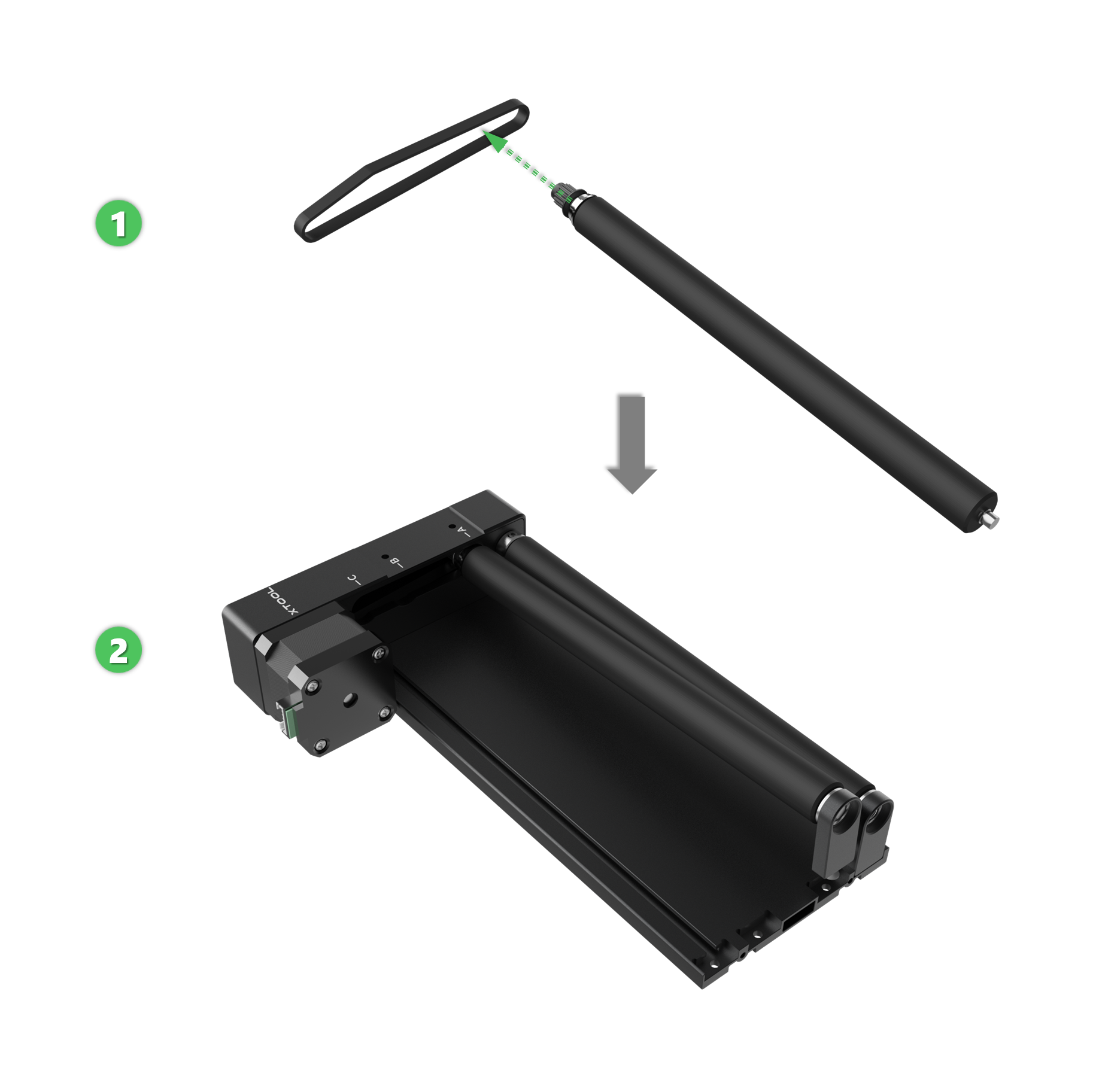

Test B: Assembly verification (RA 2 Only)

If you have previously disassembled the Rotary Attachment 2:

- Verify correct assembly:

- Check that all roller shafts and clamps are properly installed.

- Reference installation guide:

- Compare your assembly with the official installation steps.

- If uncertain, take clear photos of your roller chucks/clamps and send them to xTool Customer Service for verification.

- Reassemble if necessary:

- If assembly appears incorrect, carefully reassemble following the installtion diagram below.

Test C: Power-on manual operation

- Power on your xTool S1 main unit.

- Connect your accessory (xTool RA 2 or xTool Conveyor Feeder).

- Test manual operation:

- For xTool RA 2: Manually rotate the attachment by hand.

- For xTool Conveyor Feeder: Manually push/pull the conveyor belt.

- Evaluate results:

- Stiff, blocked, or jerky movement: Try replacing the accessory connection cable.

- Smooth movement: Proceed to Step 2.

- If you don't have a replacement cable available, proceed to Step 2.

Step 2: Isolate rear interface board

Purpose: Identify if the rear interface board or connected accessories are causing issues.

Note: A short circuit or failure in the rear interface board (where accessories like the Air Assist Set or Fire Safety Set connect) is a common cause of this problem.

Test A: Disconnect Air Assist & Fire Safety Set (If applicable)

- Disconnect all accessories:

- Unplug xTool Air Assist Set (if connected).

- Unplug xTool Fire Safety Set (if connected).

- Test accessory operation:

- Run a test operation with your xTool RA2 or Conveyor Feeder.

- Observe if there are stuttering, blocking, or unusual noises.

- Evaluate results:

- Problem resolved: The disconnected accessory has a failed connection cable and needs connection cable replacement.

- Problem persists: Proceed to Test B.

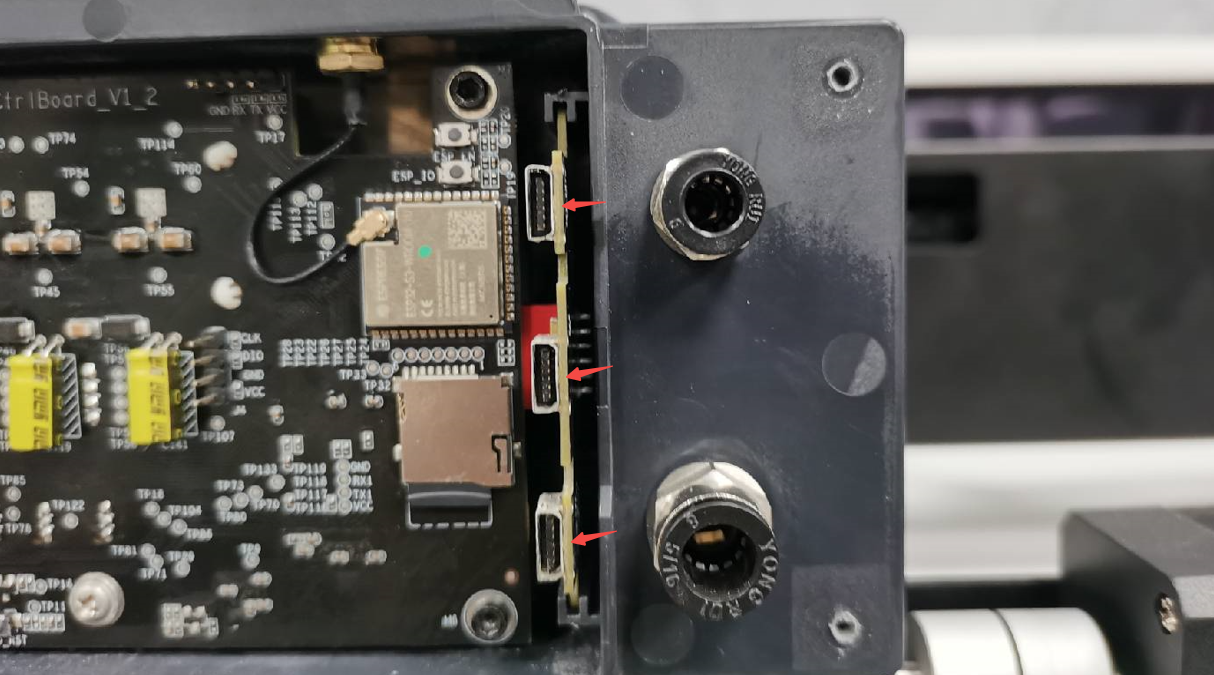

Test B: Inspect rear interface board

- Access the main board:

- Follow the video guide below to remove the main control board protective cover.

- Visual inspection:

- Examine the 3 accessory extension connection ports on the rear interface board.

- Check for signs of deformation, burning, or physical damage.

- Evaluate results:

- Visible damage or deformation: Replace the rear interface board.

- No visible damage: Proceed to Test C.

Test C: Disconnect rear interface board

- Disconnect the rear interface board:

- Unplug the rear interface board from the main control board.

- Test attachment operation:

- Run a test operation with your xTool RA2 or Conveyor Feeder.

- Observe if there are stuttering, blocking, or unusual noises.

- Evaluate results:

- Problem resolved: Replace both the rear interface board and its connection cable.

- Problem persists: Proceed to Step 3.

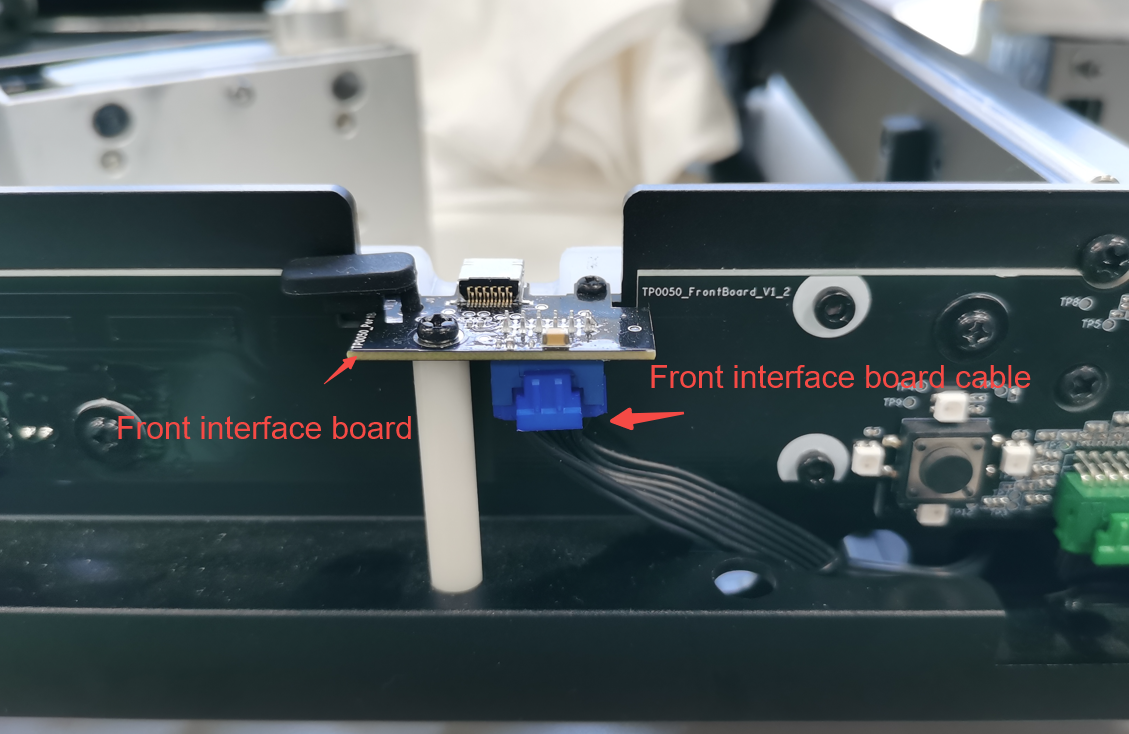

Step 3: Check front interface board & cable

Purpose: Identify issues with the front interface board or its connection cable.

Prerequisites: You have completed Step 2 and disconnected the rear interface board, but the problem persists.

Remove xTool S1 outer casing

‼️ Electrical Safety: Exercise caution when handling internal components.

- Power off your xTool S1 main unit.

- Remove the outer casing to access internal components.

Check A: Inspect front interface board cable

- Visual inspection:

- Examine the front interface board connection cable for:

- Cracked or damaged insulation;

- Broken or exposed wires;

- Loose connections;

- Examine the front interface board connection cable for:

- Evaluate results:

- Cable damage found: Replace the front interface board connection cable or contact xTool Customer Service for a replacement unit.

- Cable appears normal: Proceed to Check B.

Check B: Replace front interface board

- If the connection cable appears normal:

- The front interface board itself may be experiencing failure.

- Contact xTool Customer Service to obtain a replacement front interface board.

- Install the new board and test accessory operation again.

Step 4: Check main control board

Purpose: Determine if the main control board of xTool S1 is causing the issue.

Note: Main control board failure is uncommon and typically a last-resort diagnosis.

Prerequisites

- All previous steps have been completed.

- The problem persists despite component replacements.

Solution

- Contact xTool Customer Service to obtain a replacement main control board.

- Follow the replacement guide below to replace the failed board.

- Test accessory operation with the new main control board.

Still experiencing issues?

Should the issue persist after completing the preceding steps, submit a ticket via the "Submit a Ticket" button in the "Help Ticket" section below. The standard response time for xTool Customer Service is one business day.

For a prompt resolution, please include the following details:

- Issue description: A detailed explanation of the observed problem.

- Video evidence: Attach a video demonstrating the issue, where applicable.

- Troubleshooting performed: Any troubleshooting steps you have already attempted, along with their results.

This information is crucial for xTool technical support engineers to provide timely assistance.

Documentation feedback

Help improve this content by providing feedback. If this content did not meet your requirements, select "No" in the "Was this page helpful?" section below. Include specific details about what was unclear or missing in the pop-up suggestion box. Feedback submissions are reviewed by xTool technical writers to enhance future documentation.

Services & Help

Learn & Community

Copyright © 2025 xTool All Rights Reserved.